Bucket and Arm Movement: They power the hydraulic cylinders responsible for raising, lowering, and tilting the excavator's bucket and arm.

Boom Movement: They facilitate the extension and retraction of the excavator's boom, allowing for reaching and digging at various distances.

Swing Mechanism: They enable the rotation of the excavator's upper structure, allowing it to pivot and maneuver for digging in different directions.

Traveling: They drive the hydraulic motors that propel the excavator's tracks or wheels, enabling it to move across terrain.

Auxiliary Functions: They may also power auxiliary attachments and functions, such as hydraulic thumbs, hydraulic hammers, or hydraulic couplers for quick attachment changes.

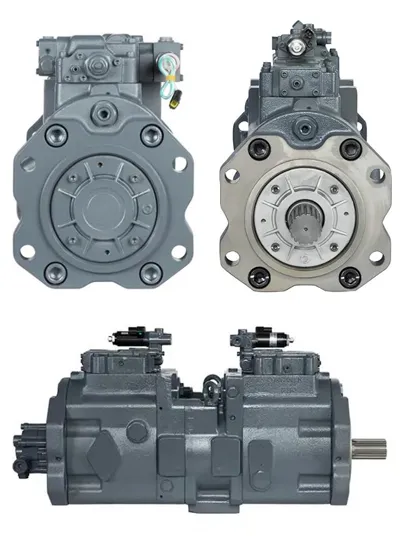

The hydraulic pump in an excavator is responsible for converting mechanical power into hydraulic power. Its main function is to generate the necessary hydraulic pressure to operate various hydraulic components, such as cylinders, motors, and valves, allowing the excavator to perform tasks such as lifting, digging, and moving materials efficiently. Essentially, the hydraulic pump powers the hydraulic system of the excavator, enabling it to perform a wide range of functions with precision and power.

There are a pair of gears or plungers that mesh with each other inside the hydraulic pump body, forming a certain volume inside the pump body. When the transmission shaft of the hydraulic pump rotates, the gear or plunger rotates accordingly, thereby changing the volume of the pump chamber.

When the volume of the pump chamber increases, the pressure inside the pump decreases, and hydraulic oil enters the pump chamber through the suction port; When the volume of the pump chamber decreases, the pressure inside the pump increases, and hydraulic oil flows out of the pump chamber through the pressure port.

Through this working principle, the hydraulic pump can continuously suck in and discharge hydraulic oil, forming stable hydraulic energy

Common signs of hydraulic pump failure in excavators include loss of hydraulic power, unusual noises, fluid leaks, erratic operation, overheating, increased fuel consumption, contaminated hydraulic fluid, and warning lights or alarms.

Smaller excavators, such as mini and compact excavators, often use gear pumps or vane pumps due to their simplicity, compact size, and cost-effectiveness. These pumps provide enough hydraulic power for light to moderate digging and lifting tasks typically performed by smaller excavators.

Medium to large-sized excavators, including standard and heavy-duty excavators, typically use piston pumps. Piston pumps offer higher efficiency, reliability, and the ability to generate higher pressures, making them suitable for heavy-duty digging, lifting, and other demanding tasks.

In addition, many modern excavators, regardless of size, may use a combination of different types of hydraulic pumps, including variable displacement pumps for precise control and fixed displacement pumps for consistent flow rates.

Replacing a faulty hydraulic pump in your excavator can be a complex task and typically requires professional servicing. Hydraulic systems are intricate and critical components of excavators, and improper installation or handling during pump replacement can lead to further damage or malfunction. Professional technicians have the expertise and specialized tools necessary to diagnose hydraulic pump issues accurately and ensure proper installation and calibration of the new pump. Attempting to replace the pump without the appropriate knowledge and experience may result in safety hazards, reduced performance, or additional repair costs. Therefore, it is advisable to seek professional servicing for hydraulic pump replacement in excavators.

The frequency of checking and maintaining the hydraulic pump in your excavator depends on several factors, including the manufacturer's recommendations, the age and usage of the equipment, and the operating conditions. As a general guideline, it is recommended to inspect and maintain the hydraulic pump as part of routine equipment maintenance, which may occur at regular intervals such as every 250 to 500 operating hours or as specified in the excavator's maintenance manual. Additionally, it is essential to monitor the performance of the hydraulic system regularly and address any signs of unusual noise, leaks, or decreased efficiency promptly. Adhering to a proactive maintenance schedule can help prevent costly downtime and extend the lifespan of the hydraulic pump and other critical components of the excavator.

Gear Pumps:Simple and cost-effective.Used in smaller excavators.Noisy operation.

Vane Pumps:More efficient and quieter.Suitable for medium-sized excavators.Medium pressure applications.

Piston Pumps:Most efficient and versatile.Used in large excavators.High pressure capabilities.

Variable Displacement Pumps:Adjustable flow rates and pressure.Energy-efficient.Used in excavators with changing demands.

Fixed Displacement Pumps:Constant flow rate.Simple design and lower cost.Suitable for consistent hydraulic power needs.

To enhance your excavator's hydraulic pump system efficiency, focus on regular maintenance, optimal fluid selection, and minimizing pressure drops. Ensure components are properly sized, and consider upgrading to more efficient ones. Implementing variable speed drives and load-sensing systems can match pump output to demand, while proper operator training can reduce unnecessary idling. Monitor system performance to identify and address inefficiencies promptly, leading to improved productivity and reduced operating costs.

For optimal performance, it's recommended to perform maintenance on your excavator's hydraulic pump according to the manufacturer's guidelines. Typically, this involves regular inspections and servicing at specified intervals, which may vary based on factors such as operating conditions, usage frequency, and environmental factors. A common schedule includes routine checks during scheduled maintenance intervals, such as every 250 to 500 operating hours or annually, along with more frequent inspections for signs of leaks, contamination, or abnormal operation. Adhering to a consistent maintenance schedule helps ensure the longevity and reliability of your excavator's hydraulic pump system.