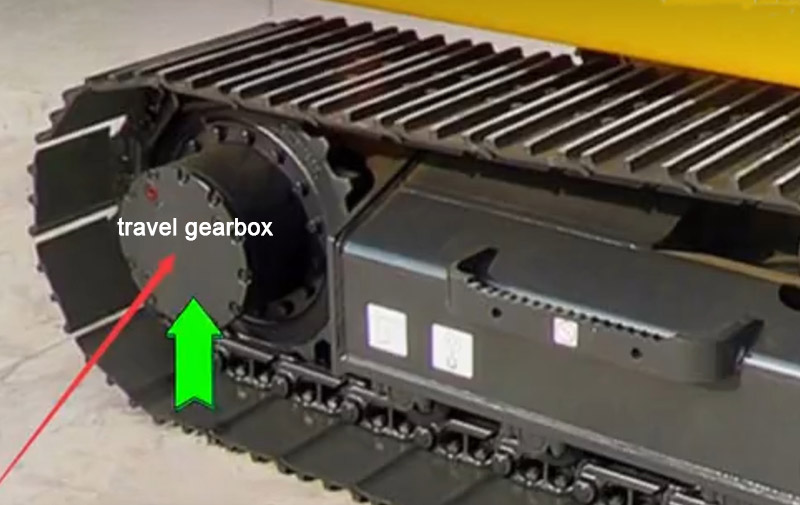

Excavators are essential machines in the construction and mining industries, known for their versatility and ability to handle various heavy-duty tasks. However, due to their complex nature and constant use, excavators can sometimes experience operational issues. One common problem reported by operators is the difficulty in walking or moving the excavator. If your Volvo excavator is experiencing walking difficulties, it is crucial to address the issue promptly to avoid prolonged downtime and potential damage to the machine. In this blog, we will delve into six detailed methods to troubleshoot and resolve walking difficulties in your Volvo excavator, ensuring it continues to perform efficiently and effectively.

Excavators are composed of multiple intricate parts working in harmony. Over time, due to continuous use, some components may develop faults, leading to operational issues such as difficulty in walking or moving. When your Volvo excavator experiences such problems, it is essential to conduct a thorough inspection to identify and resolve the root cause. Here are six comprehensive methods to help you troubleshoot and fix walking difficulties in your Volvo excavator:

Firstly, operate the walking control handle and listen for the sound of the engine refueling. If you do not hear this sound, it may indicate an issue with the engine or the control system. To diagnose further, open the data output of the automatic control system maintenance program, operate the walking control handle, and check if the pressure relay has failed. If the pressure relay is functioning correctly, the issue might lie with the engine, which should be checked and repaired if necessary.

Low travel pilot oil pressure can significantly affect the walking capabilities of your excavator. To diagnose this, check the travel pilot pressure and operate the travel pilot handle. If you notice any abnormalities, the pilot valve might be the culprit. Common issues include insufficient stroke (requiring adjustment), a too-soft pressure regulating spring (needing replacement), or a stuck, damaged, or worn valve stem (requiring cleaning, repair, or replacement).

The mutual injection relief valve plays a crucial role in maintaining the hydraulic pressure required for smooth movement. To check its functionality, connect pressure gauges to the pressure measuring ports of the front and rear pumps, block the crawler tracks, and operate the walking joystick. If the pressure readings are abnormal, you may need to test and adjust the overflow pressure of the mutual injection relief valve to ensure it is within the correct range.

Central rotary joint leakage can lead to significant operational issues, including difficulty in walking. To check for leakage, disassemble the two high-pressure pipe joints and plug them with appropriate plugs. Then, operate the travel joystick and observe if a substantial amount of oil flows out from the oil port of the rotary joint. If there is significant leakage, it indicates a serious issue that needs to be addressed immediately.

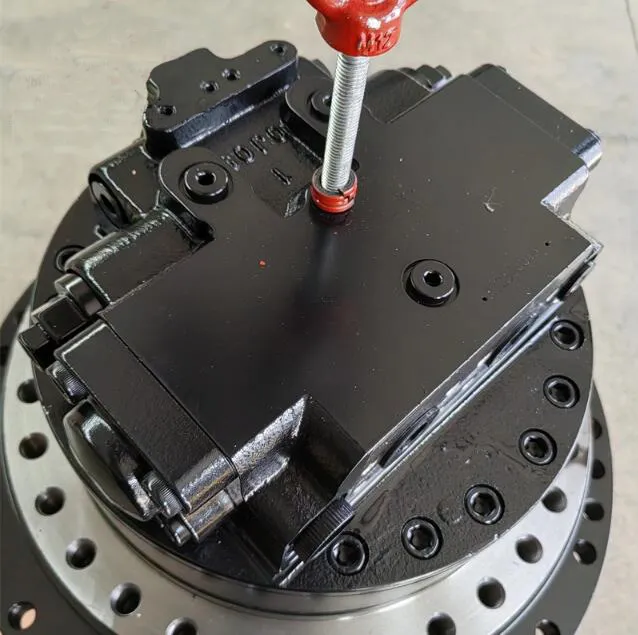

Motor leakage is another potential cause of walking difficulties. To inspect the motor, disassemble the motor drain pipe and check for excessive leakage. If you find serious leakage, it might be necessary to repair or replace the motor to restore proper functionality.

The multi-way valve controls the hydraulic flow to various parts of the excavator. If this valve is stuck in a semi-closed position or has excessive fitting gaps causing severe leakage, the excavator’s movement will be weak. In such cases, the valve stem and valve sleeve need to be repaired to ensure smooth operation.

For an excavator to perform normal and smooth construction activities, every movement must be perfectly coordinated and connected. This requires experienced operators who not only focus on the construction environment but also closely monitor each movement of the excavator to ensure it is functioning correctly. Timely identification and resolution of any operational issues can significantly enhance the efficiency and lifespan of the excavator.

Walking difficulties in Volvo excavators can disrupt construction activities and lead to costly downtime. By understanding the potential causes and implementing the six detailed methods outlined above, operators can effectively troubleshoot and resolve these issues. Regular maintenance and proactive inspections are key to ensuring that the excavator continues to perform optimally. Addressing walking difficulties promptly not only minimizes downtime but also extends the lifespan of the excavator, contributing to more efficient and cost-effective operations.

Q1: What should I do if my Volvo excavator’s walking control handle does not produce the sound of engine refueling?

A1: If you do not hear the sound of engine refueling when operating the walking control handle, you should open the data output of the automatic control system maintenance program, operate the walking control handle, and check if the pressure relay has failed. If the pressure relay is functioning correctly, inspect and repair the engine as needed.

Q2: How can I check for low travel pilot oil pressure in my Volvo excavator?

A2: To check for low travel pilot oil pressure, examine the travel pilot pressure and operate the travel pilot handle. If abnormalities are detected, inspect and repair the pilot valve, checking for issues such as insufficient stroke, a too-soft pressure regulating spring, or a stuck, damaged, or worn valve stem.

Q3: What is the procedure for evaluating the mutual injection relief valve pressure?

A3: To evaluate the mutual injection relief valve pressure, connect pressure gauges to the pressure measuring ports of the front and rear pumps, block the crawler tracks, and operate the walking joystick. If the pressure readings are abnormal, test and adjust the overflow pressure of the mutual injection relief valve as needed.

Q4: How can I detect central rotary joint leakage in my excavator?

A4: To detect central rotary joint leakage, disassemble the two high-pressure pipe joints and plug them with appropriate plugs. Operate the travel joystick and observe if a substantial amount of oil flows out from the oil port of the rotary joint. Significant leakage indicates a serious issue that needs to be addressed immediately.