Excavators are powerful machines commonly used in construction and mining industries. One of the critical components that enable these machines to perform a variety of tasks is the hydraulic system. This blog post will delve into the intricacies of how an excavator hydraulic system works.

Hydraulic systems operate based on Pascal’s Law, which states that pressure applied to a confined fluid is transmitted equally in all directions. This principle is fundamental in converting mechanical energy into hydraulic energy, allowing excavators to perform heavy-duty tasks with precision and efficiency.

An excavator hydraulic system comprises several key components, each playing a crucial role in its operation. These components include:

Each of these components works in unison to ensure the efficient operation of the excavator, allowing it to lift, dig, and move materials effectively.

The hydraulic pump is the primary source of power in an excavator hydraulic system. It draws hydraulic fluid from the reservoir and pressurizes it, creating a flow of fluid that powers the entire system.

There are several types of hydraulic pumps used in excavators, including gear pumps, vane pumps, and piston pumps. Each type has its own advantages and is selected based on the specific requirements of the excavator.

When the excavator’s engine is running, it drives the hydraulic pump, causing it to draw hydraulic fluid from the reservoir. The pump pressurizes the fluid and sends it through the system’s hydraulic lines. This pressurized fluid is then directed to the various hydraulic cylinders and motors, initiating movement.

Hydraulic fluid plays a critical role in the operation of an excavator hydraulic system. It serves as the medium for transmitting power and also performs several other vital functions.

Hydraulic fluid must possess specific properties to ensure the efficient operation of the system. These properties include:

In addition to transmitting power, hydraulic fluid performs several other essential functions, including:

By performing these functions, hydraulic fluid ensures the reliable and efficient operation of the excavator hydraulic system.

Hydraulic cylinders are a crucial component of the excavator hydraulic system, responsible for converting hydraulic energy into mechanical movement. They enable the excavator to perform tasks such as lifting, digging, and pushing.

There are several types of hydraulic cylinders used in excavators, each designed for specific applications. These include:

Hydraulic cylinders consist of a cylinder barrel, a piston, and a piston rod. When pressurized hydraulic fluid is directed into the cylinder, it pushes the piston, causing the piston rod to extend or retract. This movement translates into the mechanical action required for the excavator’s various tasks.

For example, when the operator activates the control valve to lift the boom, pressurized fluid is directed into the boom cylinder, causing it to extend and lift the boom. Conversely, when the operator wants to lower the boom, the control valve directs fluid to the opposite side of the cylinder, causing it to retract and lower the boom.

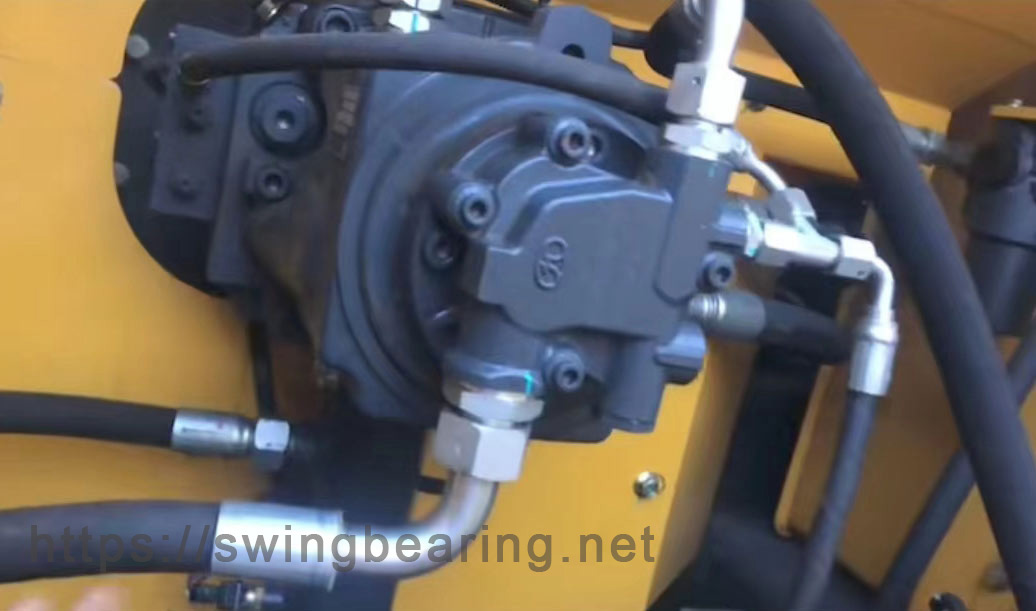

Hydraulic motors are essential components of the excavator hydraulic system, responsible for driving various functions such as the rotation of the cab and the movement of the tracks.

There are several types of hydraulic motors used in excavators, including gear motors, vane motors, and piston motors. Each type has its own advantages and is selected based on the specific requirements of the excavator.

Hydraulic motors convert hydraulic energy into mechanical energy by using pressurized hydraulic fluid. When pressurized fluid is directed into the motor, it causes the motor’s internal components to move, generating rotational motion. This motion is then used to drive the excavator’s various functions.

For example, when the operator activates the control valve to rotate the cab, pressurized fluid is directed into the hydraulic motor responsible for cab rotation. The motor converts the hydraulic energy into rotational motion, causing the cab to rotate.

Control valves are critical components of the excavator hydraulic system, responsible for regulating the flow of hydraulic fluid and ensuring precise control over the machine’s movements.

There are several types of control valves used in excavators, including:

Control valves operate by opening and closing passages within the hydraulic system, directing the flow of pressurized fluid to the desired components. The operator uses the control levers or joysticks in the cab to activate the control valves, initiating the desired movement.

For example, when the operator wants to extend the boom, they move the control lever, causing the directional control valve to open the passage for pressurized fluid to flow into the boom cylinder. This action extends the cylinder, lifting the boom. When the operator wants to lower the boom, they move the control lever in the opposite direction, causing the directional control valve to open the passage for fluid to flow out of the cylinder, lowering the boom.

By regulating the flow of hydraulic fluid, control valves ensure precise and accurate control over the excavator’s movements, allowing the operator to perform tasks with efficiency and precision.

Proper maintenance and timely troubleshooting are essential to ensure the reliable and efficient operation of an excavator hydraulic system. Regular maintenance helps prevent system failures and extends the lifespan of the components.

By following these maintenance tips and addressing common issues promptly, you can ensure the reliable and efficient operation of your excavator hydraulic system.

The excavator hydraulic system is a complex and vital component that enables the machine to perform a variety of tasks with precision and efficiency. Understanding the operation of the hydraulic pump, fluid, cylinders, motors, and control valves is essential for maintaining and troubleshooting the system effectively. By following proper maintenance practices and addressing issues promptly, you can ensure the longevity and reliability of your excavator hydraulic system, allowing it to perform at its best on the job site.