Hydraulic piston pumps play a pivotal and indispensable role in powering hydraulic systems, serving as the primary source of energy transfer in a wide array of industrial applications. Understanding the intricate technology behind hydraulic piston pumps is paramount for optimizing system performance, efficiency, and reliability. In this comprehensive blog post, we will delve deeply into the complexities of hydraulic piston pump technology, exploring its multifaceted functions, intricate components, diverse types, and cutting-edge advancements in the field of hydraulic engineering.

Hydraulic piston pumps serve as the mechanical workhorses responsible for converting mechanical energy into hydraulic energy, which is then harnessed to drive a myriad of hydraulic actuators, motors, and cylinders in industrial machinery. These precision-engineered pumps generate high-pressure fluid flow that powers the movement of heavy loads, operates hydraulic tools with precision, and facilitates seamless and accurate control in a wide spectrum of equipment operations, ranging from heavy-duty construction machinery to intricate manufacturing processes.

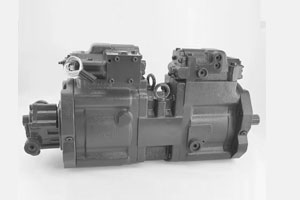

Types of Hydraulic Piston Pumps

Axial Piston Pumps:

Axial piston pumps represent a widely used and highly efficient type of hydraulic pump known for their compact design and exceptional performance characteristics. These pumps feature pistons arranged in an axial or linear fashion within a cylinder block, where the reciprocating motion of the pistons generates hydraulic flow. The unique circular arrangement of the pistons allows for smooth and continuous fluid delivery, making axial piston pumps ideal for applications requiring high pressure and variable flow rates.

One of the key advantages of axial piston pumps is their ability to provide precise control over fluid flow and pressure, enabling operators to adjust output according to specific operational requirements. This level of precision and control is essential in demanding industrial applications where accuracy and reliability are paramount. Additionally, axial piston pumps are known for their high efficiency, as they minimize energy losses and optimize hydraulic system performance.

The compact design of axial piston pumps makes them suitable for integration into a wide range of hydraulic systems, including mobile equipment, industrial machinery, and automotive applications. Their versatility, reliability, and ability to operate at high speeds make them a preferred choice for applications that require dynamic fluid delivery and precise control over hydraulic power. Overall, axial piston pumps are valued for their efficiency, performance, and durability in demanding industrial environments.

Radial Piston Pumps:

Radial piston pumps are another type of hydraulic pump that features pistons arranged in a radial configuration around a central driveshaft. This unique design enables radial piston pumps to deliver exceptional power density, smooth operation, and the ability to handle extreme pressure requirements with unparalleled performance and reliability. The radial arrangement of pistons allows for efficient fluid delivery and high power output, making these pumps well-suited for applications that demand robust performance and operational precision.

One of the defining characteristics of radial piston pumps is their ability to generate high levels of hydraulic pressure, making them ideal for applications where intense force or power is required. The radial configuration of pistons ensures uniform distribution of force, resulting in smooth and consistent fluid flow even under challenging operating conditions. This reliability and performance make radial piston pumps a preferred choice for industrial applications that prioritize power output, operational efficiency, and system reliability.

In addition to their high-pressure capabilities, radial piston pumps are valued for their durability and longevity, making them a cost-effective solution for industries that require reliable hydraulic power sources. The smooth operation and efficient fluid delivery of radial piston pumps contribute to overall system performance and productivity, allowing operators to achieve optimal results in demanding applications. Overall, radial piston pumps are recognized for their exceptional power density, reliability, and performance in challenging industrial environments.

Variable Displacement Capability:

In the realm of hydraulic piston pump technology, significant advancements have been made in the integration of variable displacement capabilities. Modern hydraulic piston pumps are now equipped with cutting-edge variable displacement technology that allows for real-time adjustments of flow rates and pressure levels. This dynamic capability enables hydraulic systems to adapt to the changing demands of complex industrial applications, enhancing overall system efficiency, flexibility, and performance. By offering the flexibility to tailor output to specific operational requirements, variable displacement technology has become a cornerstone of modern hydraulic systems, ensuring optimal performance and precise power delivery in a wide range of industrial settings.

High-Speed Operation:

The continuous evolution of hydraulic piston pump technology has led to remarkable progress in high-speed operation capabilities. Through advancements in pump design, materials, and engineering practices, hydraulic piston pumps are now capable of operating at significantly higher speeds, resulting in improved response times and enhanced productivity in industrial applications. High-speed operation ensures rapid and precise hydraulic power delivery, enabling critical industrial operations to be carried out with efficiency and precision. As a result, the ability to operate at increased speeds has become a key feature of modern hydraulic piston pump technology, empowering industries to achieve higher levels of performance and operational effectiveness.

Integrated Electronics and Smart Pump Technology:

The integration of advanced electronic components, sensors, controllers, and intelligent feedback systems has ushered in a new era of smart pump technology in hydraulic systems. Modern hydraulic piston pumps are now equipped with integrated electronics that enable sophisticated system monitoring, diagnostics, and predictive maintenance capabilities. By leveraging real-time data analysis and intelligent feedback mechanisms, smart pump technology enhances operational efficiency, optimizes system performance, and enables proactive maintenance strategies. This transformative integration of electronics and smart technologies has revolutionized the way hydraulic systems are monitored, maintained, and optimized, leading to enhanced reliability and performance in industrial applications.

Energy Efficiency and Sustainability:

With a growing focus on environmental sustainability, manufacturers are increasingly prioritizing the development of energy-efficient hydraulic piston pumps that align with eco-friendly design principles. Modern hydraulic piston pumps are designed to minimize power consumption, reduce heat generation, and incorporate sustainable features to meet the demand for greener hydraulic solutions in industrial applications. By enhancing energy efficiency and sustainability, these innovative hydraulic pumps not only contribute to environmental conservation but also offer long-term cost savings and operational benefits to industries seeking to reduce their carbon footprint. The emphasis on energy efficiency and sustainability in hydraulic piston pump technology reflects a commitment to delivering high-performance solutions that prioritize both environmental responsibility and operational excellence.

In conclusion, hydraulic piston pumps stand as the indispensable core components of hydraulic systems, embodying precision engineering, advanced technology, and unparalleled performance to drive the operational excellence, productivity, and sustainability of diverse industrial processes and applications. By delving deep into the multifaceted aspects of hydraulic piston pump technology, including functions, types, components, and advancements, we gain invaluable insights into their pivotal role in enhancing operational efficiency, precision, and environmental sustainability across a broad spectrum of industries. This comprehensive understanding empowers engineers, technicians, and operators to harness the full potential of hydraulic piston pumps, implement innovative solutions, optimize system performance, and propel industrial processes towards a more efficient, reliable, and environmentally conscious future.

Question 1: What is a hydraulic piston pump?

Answer: A hydraulic piston pump is a type of positive displacement pump that uses reciprocating pistons to generate hydraulic fluid flow. The pistons move back and forth within cylinders to pressurize the fluid and deliver it to the hydraulic system.

Question 2: What are the main types of hydraulic piston pumps?

Answer: The main types of hydraulic piston pumps include axial piston pumps and radial piston pumps. Axial piston pumps have pistons arranged in a linear fashion, while radial piston pumps have pistons arranged in a radial configuration around a central driveshaft.

Question 3: What are the advantages of hydraulic piston pumps?

Answer: Hydraulic piston pumps offer advantages such as high efficiency, precise control over fluid flow and pressure, compact design, reliability, high power density, and the ability to handle extreme pressure requirements. They are commonly used in industrial applications requiring variable flow rates, high pressure, and operational precision.