Excavator track motors are crucial components that drive the movement of excavators, enabling them to navigate various terrains efficiently. In this comprehensive guide, we will delve into the intricacies of track motors, their types, maintenance methods, and troubleshooting tips to ensure optimal performance and longevity of your excavator.

Track motors, also known as travel motors or final drive motors, are hydraulic components that power the tracks of an excavator, allowing it to move forward, backward, and turn. These motors convert hydraulic energy into mechanical energy, driving the tracks and enabling the excavator to traverse different terrains.

The efficiency and reliability of track motors are critical for the overall performance of an excavator. Properly functioning track motors ensure smooth movement, precise control, and optimal power transmission, contributing to the excavator’s productivity and operational efficiency. 🚜

Hydraulic track motors are the most common type used in excavators. They offer excellent torque, smooth operation, and precise control. Hydraulic motors are highly efficient and can handle heavy loads, making them ideal for demanding construction and excavation tasks.

Electric track motors are gaining popularity due to their energy efficiency and low environmental impact. They provide instant torque, smooth acceleration, and require less maintenance compared to hydraulic motors. Electric motors are ideal for applications where noise reduction and emissions control are essential.

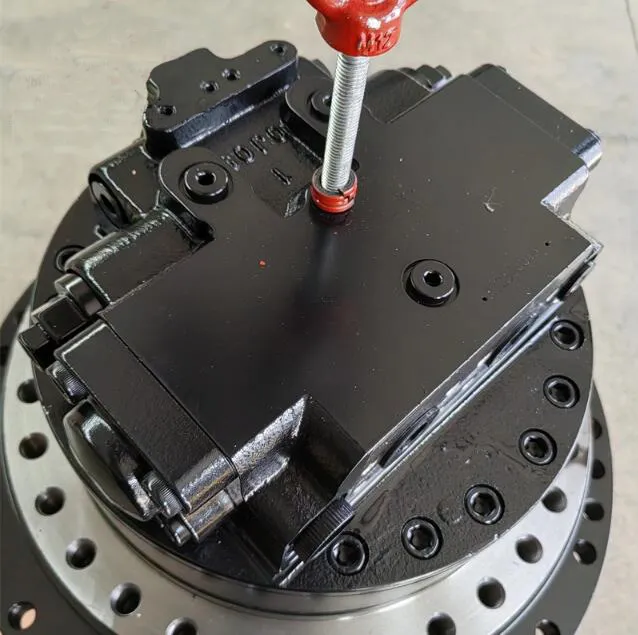

Planetary gear track motors are known for their compact design and high torque output. They use a system of gears to distribute the load evenly, reducing wear and tear and increasing the motor’s lifespan. These motors are ideal for heavy-duty applications that require robust performance.

Track motors work by converting hydraulic or electric energy into mechanical energy. In hydraulic track motors, hydraulic fluid is pumped into the motor, creating pressure that drives the motor’s internal components. This pressure is converted into rotational motion, which powers the tracks.

The hydraulic pump generates the pressure required to drive the hydraulic motor. It is typically powered by the excavator’s engine and is responsible for delivering hydraulic fluid to the motor.

The control valve regulates the flow of hydraulic fluid to the motor, allowing precise control over the excavator’s movement. It ensures that the right amount of fluid reaches the motor, depending on the operator’s input.

The motor housing contains the internal components of the track motor, including gears, pistons, and bearings. It is designed to withstand high pressure and protect the motor’s internal parts from damage.

The final drive is the component that directly powers the tracks. It consists of gears and shafts that transfer the motor’s rotational motion to the tracks, enabling the excavator to move.

Regular inspection and cleaning of track motors are essential to ensure their longevity and optimal performance. Dirt, debris, and contaminants can cause wear and tear, reducing the motor’s efficiency and lifespan.

Proper lubrication is crucial to reduce friction, prevent wear and tear, and ensure smooth operation of track motors. It helps to extend the motor’s lifespan and maintain its efficiency.

Over time, track motors can experience wear and tear, reducing their efficiency and performance. Signs that it may be time to upgrade or replace your track motor include:

When upgrading or replacing your track motor, consider the following factors to ensure you choose the right motor for your excavator:

Excavator track motors are essential components that drive the movement and performance of your excavator. Understanding the different types of track motors, their working principles, and proper maintenance methods is crucial to ensuring their longevity and efficiency. Regular inspection, cleaning, and lubrication, along with timely upgrades and replacements, will keep your excavator in top condition and maximize its productivity.

By following the guidelines in this comprehensive guide, you can ensure that your excavator’s track motors operate smoothly and efficiently, allowing you to tackle even the most challenging tasks with ease. Happy excavating!