The hydraulic system is the heart of an excavator, enabling it to perform heavy lifting, digging, and other powerful functions with precision and efficiency. In this comprehensive blog, we will delve into the intricacies of hydraulic system design for excavators, exploring its key components, functionality, and the importance of proper maintenance. With a focus on the keyword “hydraulic system,” this article aims to provide a detailed overview that will be beneficial for both industry professionals and enthusiasts.

A hydraulic system uses fluid under pressure to generate, control, and transmit power. In excavators, this system allows for the manipulation of the machine’s boom, arm, and bucket, enabling it to perform a variety of tasks such as digging, lifting, and moving heavy materials. The hydraulic system is favored for its ability to provide smooth, precise movements and its capacity to handle large loads with ease.

The hydraulic pump is the core of the hydraulic system, responsible for converting mechanical energy into hydraulic energy by moving fluid from the reservoir to the actuators. There are different types of hydraulic pumps used in excavators, including gear pumps, vane pumps, and piston pumps, each with its specific advantages and applications.

Hydraulic cylinders are actuators that convert hydraulic energy back into mechanical energy. They are used to extend and retract the boom, arm, and bucket of the excavator. Cylinders are typically made of high-strength steel to withstand the high pressures they operate under.

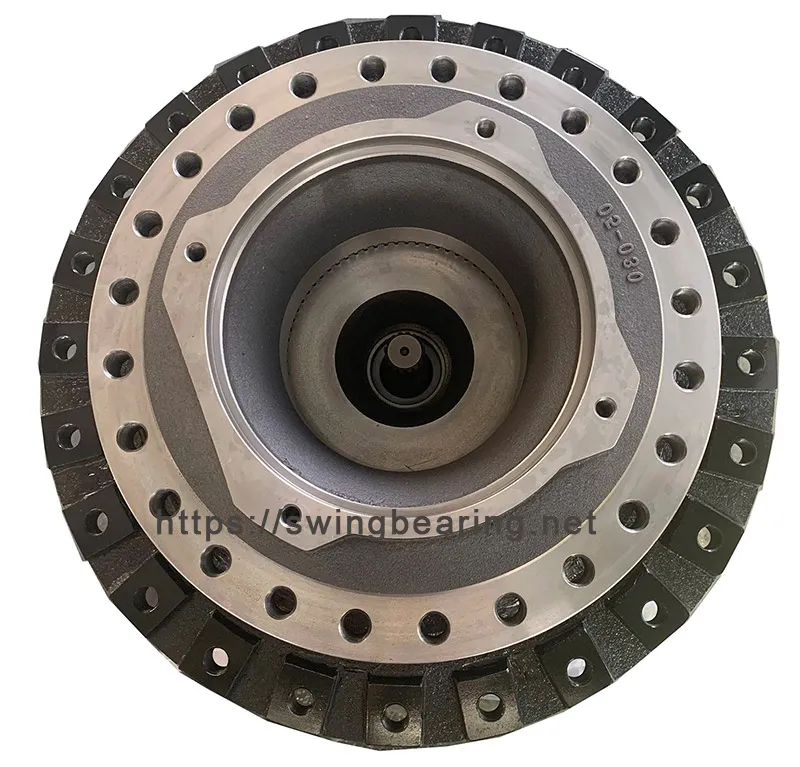

Hydraulic motors convert hydraulic energy into rotational mechanical energy. In excavators, they are used to drive the tracks and enable the machine to move. Hydraulic motors are essential for providing the necessary torque and speed for the excavator’s mobility.

Control valves regulate the flow and pressure of hydraulic fluid within the system. They allow the operator to control the movement of the excavator’s various parts by directing the flow of fluid to different actuators. Common types of control valves include directional control valves, pressure relief valves, and flow control valves.

Hydraulic fluid, often referred to as hydraulic oil, is the medium through which power is transmitted in the system. It also serves to lubricate moving parts, reduce friction, and dissipate heat. The choice of hydraulic fluid is crucial, as it must have properties that ensure efficient operation and longevity of the system.

The hydraulic reservoir stores the hydraulic fluid. It also allows air and moisture to separate from the fluid and provides a space for fluid expansion. The reservoir plays a critical role in maintaining the efficiency and cleanliness of the hydraulic system.

The hydraulic system in an excavator operates based on Pascal’s law, which states that pressure applied to a confined fluid is transmitted equally in all directions. When the operator manipulates the controls, the hydraulic pump sends fluid under pressure to the control valves. These valves then direct the fluid to the hydraulic cylinders or motors, causing them to move. The movement of the cylinders or motors translates into the movement of the excavator’s boom, arm, bucket, or tracks, allowing the machine to perform its tasks.

The design of an excavator’s hydraulic system must take into account the load requirements of the machine. This includes the maximum weight the excavator will lift and the forces exerted during digging. The hydraulic components must be capable of handling these loads without failure.

Excavators operate in various environments, from construction sites to mines. The hydraulic system must be designed to withstand the specific conditions of these environments, such as temperature extremes, dust, and moisture. This may involve selecting components with appropriate seals and protective coatings.

Efficiency is a key consideration in hydraulic system design. An efficient system uses less energy to perform the same amount of work, reducing fuel consumption and operating costs. This involves optimizing the hydraulic circuit to minimize losses due to friction and leakage.

Precision in controlling the excavator’s movements is crucial for tasks that require fine manipulation, such as placing pipes or excavating near existing structures. The hydraulic system must be designed to provide smooth and accurate control, with minimal lag or overshoot.

Electro-hydraulic systems combine traditional hydraulic technology with electronic control. This allows for more precise and automated control of the excavator’s functions. For example, sensors and electronic controllers can optimize the hydraulic flow and pressure in real-time, improving efficiency and performance.

Load-sensing hydraulic systems adjust the flow and pressure based on the load requirements. This means that the hydraulic pump only provides the necessary amount of fluid, reducing energy wastage and improving efficiency. Load-sensing systems are particularly useful in varying load conditions, where the demand on the hydraulic system changes frequently.

Hybrid hydraulic systems incorporate energy storage components, such as accumulators or batteries, to capture and reuse energy. For example, energy generated during the lowering of the boom can be stored and used to assist in lifting it again. This not only improves efficiency but also reduces the wear and tear on hydraulic components.

Regular maintenance is crucial for the longevity and reliability of an excavator’s hydraulic system. Neglecting maintenance can lead to reduced performance, increased fuel consumption, and even catastrophic failures. A well-maintained hydraulic system ensures that the excavator operates efficiently and safely.

Proper maintenance is crucial for the longevity and efficient operation of an excavator’s hydraulic system. Neglecting routine maintenance can lead to reduced performance, increased operational costs, and potential system failures. Here, we will delve into detailed common maintenance practices that ensure your hydraulic system remains in top condition.

Regularly checking and changing the hydraulic fluid is one of the most fundamental maintenance tasks for an excavator’s hydraulic system. Hydraulic fluid plays a critical role in transmitting power, lubricating components, and dissipating heat. Over time, this fluid can become contaminated with particles, dirt, and moisture, which significantly reduce its effectiveness.

Hydraulic filters play a vital role in maintaining the cleanliness of the hydraulic fluid by removing contaminants that can cause wear and damage to the system components.

Seals and hoses are essential components , responsible for maintaining pressure and preventing fluid leaks. Over time, these components can wear out or become damaged due to the harsh operating conditions typical of excavation work.

Hydraulic leaks not only reduce system efficiency but can also pose serious environmental hazards. Leaks can occur at various points in the system, including fittings, seals, hoses, and connections.

By adhering to these detailed maintenance practices, you can ensure that your excavator’s hydraulic system remains efficient, reliable, and safe. Regular fluid checks and changes, filter replacement, inspection of seals and hoses, and diligent monitoring for leaks are all critical components of a comprehensive maintenance strategy that will help extend the life of your hydraulic system and improve the overall performance of your excavator.

Slow or erratic movement of the excavator’s components can indicate issues with the hydraulic system. This may be due to low fluid levels, clogged filters, or worn-out components. Identifying the root cause is essential to restoring normal operation.

Unusual noises, such as whining or knocking, can be a sign of hydraulic system problems. This could be due to air in the system, cavitation, or damaged components. Addressing these issues promptly can prevent further damage.

Hydraulic systems can overheat due to excessive friction, high ambient temperatures, or inadequate cooling. Overheating can lead to reduced fluid viscosity and damage to components. Ensuring proper cooling and ventilation is crucial to prevent overheating.

The first step in troubleshooting hydraulic system issues is to check the fluid levels. Low fluid levels can cause cavitation and reduce system efficiency. Ensure that the fluid reservoir is filled to the recommended level.

Clogged filters can restrict fluid flow and cause pressure drops. Inspect and replace the hydraulic filters as necessary to ensure proper fluid circulation.

Inspect the hoses and fittings for signs of wear, damage, or leaks. Tighten any loose fittings and replace damaged hoses to maintain system integrity.

Using pressure gauges and flow meters, test the hydraulic system’s pressure and flow. This can help identify issues such as worn pumps, faulty valves, or clogged lines.

Upgrading to high-efficiency hydraulic pumps can improve the performance and efficiency of the excavator. These pumps are designed to minimize energy losses and provide consistent fluid flow, enhancing overall system performance.

Modern control valves with electronic controls offer greater precision and reliability. Upgrading to these advanced valves can improve the accuracy and responsiveness of the hydraulic system.

Using high-quality hydraulic fluids with advanced additives can enhance the performance and longevity of the hydraulic system. These fluids provide better lubrication, reduce wear, and resist thermal breakdown.

Installing sensors and telemetry systems can provide real-time monitoring of the hydraulic system’s performance. This allows for early detection of issues and proactive maintenance, reducing downtime and improving reliability.

Analyzing data from the hydraulic system can identify trends and predict potential failures. Implementing predictive maintenance strategies based on this data can prevent unexpected breakdowns and extend the lifespan of the hydraulic components.

In conclusion, the hydraulic system is a critical component of an excavator, enabling it to perform a wide range of tasks with precision and efficiency. Understanding the design, maintenance, and troubleshooting of hydraulic systems is essential for ensuring the optimal performance and longevity of the excavator. By selecting the right components, following proper maintenance practices, and implementing advanced monitoring systems, operators and maintenance personnel can maximize the benefits of the hydraulic system and keep the excavator running smoothly.