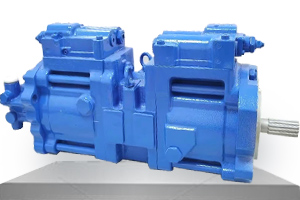

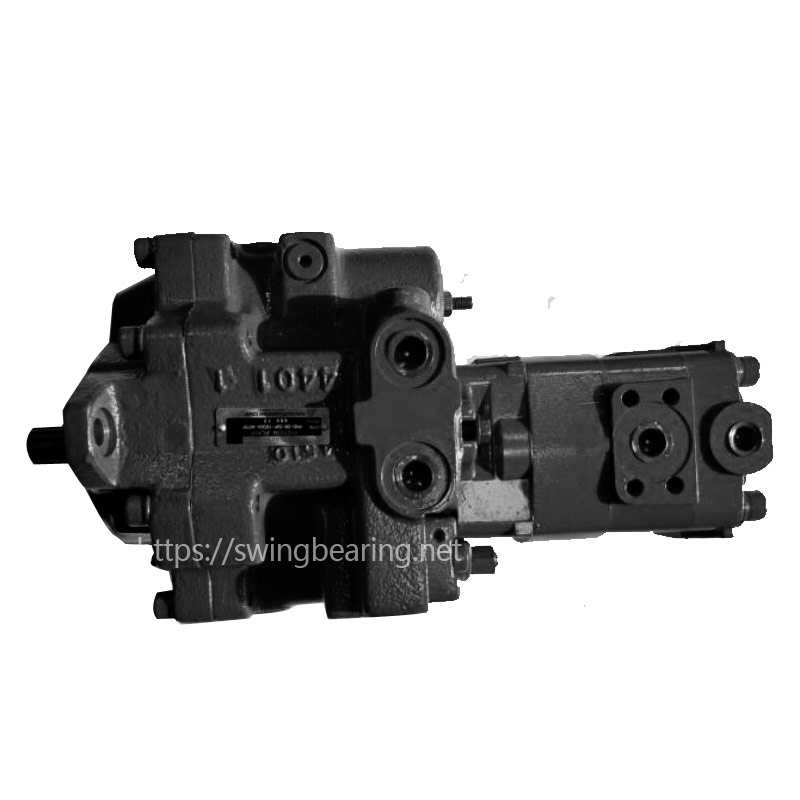

Hydraulic pumps are the heart of an excavator, dictating its power and efficiency. Properly adjusting the flow of an excavator’s хидравлична помпа is crucial to ensure optimal performance and longevity of the machinery. This guide will provide a detailed, step-by-step approach to adjusting the hydraulic pump flow, ensuring your excavator operates at its best.

Excavators are essential machines in construction and heavy-duty industries. Their hydraulic systems, driven by hydraulic pumps, control the machine’s movements and power. Understanding how to adjust the hydraulic pump flow is vital for maintaining the excavator’s performance, preventing system overload, and avoiding potential damage. This blog will walk you through the comprehensive process of adjusting the hydraulic pump flow in your excavator, ensuring smooth and efficient operations.

1. Loosen the Flow Lock Nut

The first step in adjusting the main pump flow is to loosen the flow lock nut. This nut secures the flow adjustment bolt in place, preventing unintended adjustments during operation. Use an appropriate wrench to loosen the nut, allowing access to the adjustment bolt.

2. Turn the Pressure Adjusting Bolt

Once the flow lock nut is loosened, turn the pressure adjusting bolt until the system pressure meets the required specifications. This bolt controls the pressure within the hydraulic system, ensuring it operates within safe limits. Carefully monitor the pressure gauge to achieve the desired pressure.

3. Fine-Tune the Flow Adjustment Bolt

Adjusting the flow adjustment bolt is a delicate process. When the system pressure ranges between 14700-17000 kPa, turning the bolt 1/4 turn clockwise will increase the flow by approximately 18L/min, activating the first-stage spring. For pressures between 23500-34300 kPa, a 1/4 turn clockwise will increase the flow by about 10L/min, engaging the second-stage spring.

Conversely, turning the flow adjustment bolt counterclockwise will decrease the flow by the corresponding value. This bidirectional adjustment allows for precise control over the hydraulic pump flow.

4. Secure the Flow Lock Nut

After making the necessary adjustments, tighten the flow lock nut to secure the adjustment bolt in place. Ensure a tightening torque of (12±3) N·m to prevent any loosening during operation. This step is crucial for maintaining the stability and reliability of the hydraulic system.

5. Upper and Lower Pump Adjustment

The method for adjusting the flow of the upper and lower pumps is the same. Follow the steps outlined above for both pumps to ensure consistent performance across the hydraulic system.

1. Loosen the Flow Lock Nut

Begin by loosening the flow lock nut, similar to the previous adjustment. This step allows access to the flow adjustment plug, which controls the maximum flow rate of the main pump.

2. Adjust the Flow Adjustment Plug

Twist the flow adjustment plug until the flow reaches the maximum value. Turning the flow adjustment butterfly bolt 1/4 turn clockwise will decrease the flow by about 13L/min, while turning it counterclockwise 1/4 turn will increase the flow by the same amount. This precise adjustment ensures the hydraulic pump operates within its maximum capacity, optimizing performance and preventing overload.

3. Secure the Flow Lock Nut

Tighten the flow lock nut with a torque of 10N·m. This step is essential to lock the adjustments in place, maintaining the set flow rate and ensuring consistent operation.

1. Loosen the Flow Lock Nut

Start by loosening the flow lock nut to access the flow adjustment bolt for backflow regulation.

2. Adjust the Flow Adjustment Bolt

Turn the flow adjustment bolt until the flow reaches the desired maximum value. A 1/4 turn clockwise, when the system pressure is 250 kPa, will decrease the flow by about 4L/min. Turning the bolt counterclockwise 1/4 turn will increase the flow by approximately 4L/min. These adjustments help in fine-tuning the backflow, ensuring the hydraulic system operates efficiently.

3. Secure the Nut

After making the necessary adjustments, tighten the nut with an expansion torque of (12±3) N·m. This step secures the adjustments, maintaining the desired flow rates and ensuring the hydraulic system functions optimally.

Adjusting the hydraulic pump flow in an excavator is a critical maintenance task that ensures optimal performance, longevity, and safety of the machinery. By following the detailed steps outlined in this guide, you can fine-tune your excavator’s hydraulic system, preventing potential damage and enhancing operational efficiency. Regular maintenance and proper adjustments can save time, reduce costs, and extend the life of your equipment.

For more detailed guides and professional advice, check out our other blogs or contact us directly.

Q1: Why is adjusting the hydraulic pump flow important?

A1: Properly adjusting the hydraulic pump flow ensures the excavator operates efficiently, preventing system overload and potential damage. It optimizes performance, enhances safety, and extends the lifespan of the machinery.

Q2: What tools are needed to adjust the hydraulic pump flow?

A2: You will need a wrench to loosen and tighten the flow lock nut, a pressure gauge to monitor system pressure, and an appropriate tool to turn the pressure adjusting bolt and flow adjustment plug.

Q3: How often should I adjust the hydraulic pump flow?

A3: Regular adjustments should be part of your routine maintenance schedule. The frequency depends on the usage and operating conditions of your excavator. Regular checks can prevent system failures and ensure optimal performance.

Q4: What should I do if I encounter issues during the adjustment process?

A4: If you encounter any issues, ensure all connections are secure, and follow the adjustment procedures carefully. If problems persist, consult the manufacturer’s instructions or seek professional assistance to avoid further complications.

Q5: Can I adjust both the upper and lower pumps using the same method?

A5: Yes, the method for adjusting the flow of the upper and lower pumps is the same. Follow the outlined steps for both pumps to ensure consistent performance across the hydraulic system.