In the world of construction, efficiency, reliability, and performance hinge not just on the heavy machinery itself but also on the quality and suitability of its parts. Whether it’s an excavator digging foundations or a bulldozer leveling terrain, the seamless operation of these machines relies heavily on their components. This blog will explore construction equipment parts, with a special focus on excavator accessories. We will delve into the types of parts, their functions, and provide some part numbers for reference. By the end of this piece, you will have a comprehensive understanding of why these parts are crucial and how to choose the right ones for your machinery.

Construction equipment operates under demanding conditions, often in extreme environments. High-quality parts ensure these machines can withstand such stresses and perform reliably. Here are a few reasons why investing in good parts is crucial:

Excavators are versatile pieces of equipment used in various construction tasks. To perform these tasks efficiently, they require several critical components. Below, we discuss some essential excavator accessories, their functions, and provide part numbers for better understanding.

Function: Hydraulic pumps convert mechanical energy into hydraulic energy, powering the movement of the excavator’s arm, boom, and other attachments.

Popular Part Numbers:

Detailed Overview: Hydraulic pumps are the heart of an excavator’s hydraulic system. They draw in hydraulic fluid from the reservoir and pressurize it to power the machine’s hydraulic actuators. The efficiency and condition of these pumps directly affect the excavator’s performance, making regular maintenance and timely replacement crucial.

Function: Final drive motors provide the power necessary to move the excavator’s tracks or wheels, ensuring mobility and stability on various terrains.

Popular Part Numbers:

Detailed Overview: The final drive motor is a critical component responsible for the excavator’s travel function. It converts hydraulic energy into mechanical energy, driving the tracks. The motor’s design ensures it can handle the high torque and heavy loads typical in construction environments.

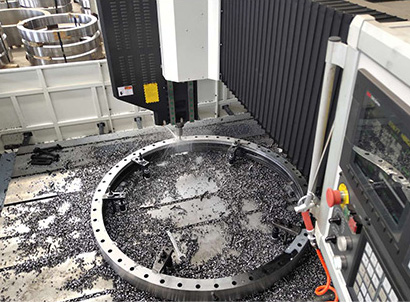

Function: Swing bearings enable the upper structure of the excavator to rotate smoothly, allowing for precise and efficient digging operations.

Popular Part Numbers:

Detailed Overview: Also known as slewing rings, swing bearings are essential for the rotational movement of the excavator’s upper structure. They support the load and provide smooth rotation, critical for operations that require precision.

Function: Bucket teeth and adapters enhance the digging capabilities of the excavator, allowing it to penetrate hard materials efficiently.

Popular Part Numbers:

Detailed Overview: Bucket teeth are wear-resistant components that attach to the excavator bucket. They come in various shapes and sizes, depending on the digging requirements. Adapters are used to secure the teeth to the bucket, ensuring they stay in place during operation.

Function: Hydraulic cylinders provide the necessary force to lift, lower, and move the excavator’s boom, arm, and bucket.

Popular Part Numbers:

Detailed Overview: Hydraulic cylinders are actuators that use hydraulic fluid pressure to produce linear motion and force. They are critical for the movement and control of the excavator’s attachments, directly impacting its operational capabilities.

Function: Control valves regulate the flow of hydraulic fluid to various parts of the excavator, ensuring smooth and precise operation.

Popular Part Numbers:

Detailed Overview: Control valves are essential for directing hydraulic fluid to different actuators within the excavator. They ensure the right amount of fluid reaches each component, enabling precise control over the machine’s functions.

Proper maintenance of excavator parts is vital to ensure longevity and optimal performance. Here are some tips for maintaining and replacing these critical components:

Understanding the various parts of construction equipment, especially excavators, is crucial for anyone involved in the construction industry. High-quality parts ensure the machinery operates efficiently, safely, and reliably. From hydraulic pumps to final drive motors and bucket teeth, each component plays a vital role in the overall functionality of the equipment. By investing in quality parts and maintaining them properly, you can extend the lifespan of your machinery and improve its performance.

A1: The hydraulic pump converts mechanical energy into hydraulic energy, powering the excavator’s arm, boom, and other attachments.

A2: Final drive motors provide the necessary power to move the excavator’s tracks or wheels, ensuring mobility and stability.

A3: Swing bearings enable the upper structure of the excavator to rotate smoothly, allowing for precise and efficient digging operations.

A4: When choosing bucket teeth, consider the material to be excavated, the size and shape of the teeth, and compatibility with the bucket.

A5: Regular maintenance helps identify and address wear and damage early, ensuring the parts operate efficiently and prolonging the lifespan of the machinery.