The CAT 330 7Y0933 Rulment cu inel de alunecare is a vital component in heavy machinery, responsible for smooth rotation and efficient operation. However, like any mechanical part, it is susceptible to wear and tear over time. One common issue that users encounter is abnormal noise during operation. This noise can be indicative of various underlying problems that, if not addressed promptly, can lead to significant damage and operational inefficiency. In this comprehensive blog, we will delve into the causes and solutions for abnormal noise in CAT 330 7Y0933 Slew Ring Bearings. By understanding these issues and their remedies, operators can ensure longer life and better performance of their equipment.

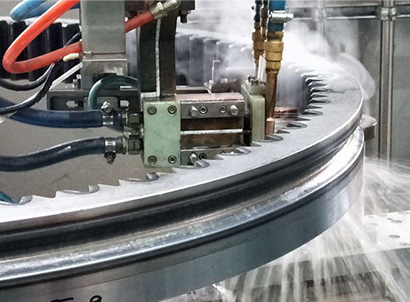

Bearing wear is one of the primary causes of abnormal noise in the CAT 330 7Y0933 Slew Ring Bearing. Over time, the inner and outer raceways of the bearing can become damaged due to various factors such as impact, severe operational faults, or general wear and tear. When these surfaces are compromised, the rolling elements may encounter imperfections like scratches or dents, leading to clear and crisp abnormal noises. These noises are often indicative of significant damage that can affect the meshing between the bearing and its associated components, resulting in periodic vibration pulses due to shaft deviation.

Wear can occur gradually or suddenly, depending on the operating conditions. For instance, heavy loads, high speeds, and harsh environmental conditions can accelerate wear. Regular inspection and maintenance are crucial to detect early signs of wear and prevent further damage.

The clearance between the shafts and the cross roller slewing bearing is crucial for optimal performance. Ideally, the axial clearance should be minimal to ensure smooth operation. However, if the rollers in the raceway are too tightly squeezed, the axial clearance becomes too small, leading to increased frictional resistance. This excessive resistance can cause severe collisions between the rolling elements and the cage holes, resulting in abnormal noise.

In some cases, the clearance might be incorrectly set during installation, or it could change over time due to operational stresses. Ensuring the correct clearance is vital, as too little clearance can lead to overheating and excessive wear, while too much clearance can result in instability and increased noise.

Foreign objects such as impurities, dust, or iron filings can enter the rolling element area of the bearing, causing severe friction with the rollers in the raceway. Even small amounts of contaminants can generate periodic or non-periodic vibration pulses, leading to abnormal noise during operation. These foreign objects can enter the bearing due to poor sealing, inadequate maintenance, or contamination during assembly.

The presence of foreign objects not only causes noise but can also lead to significant damage to the rolling elements and raceways. Regular cleaning and proper sealing are essential to prevent contaminants from entering the bearing.

The performance of the lubricant used in the bearing is crucial for its smooth operation. Using poor-quality lubricants can lead to abnormal noise due to increased friction and wear. Improper sealing of the bearing can also cause the leakage of lubricant, resulting in inadequate lubrication of the rolling elements and raceways. Furthermore, the use of abrasive lubricants can cause vibration pulses, leading to abnormal noise.

Selecting the right lubricant is essential, as it affects the bearing’s speed, load capacity, noise levels, wear resistance, and corrosion resistance. Regular monitoring and replacement of the lubricant can help maintain optimal performance and reduce the risk of abnormal noise.

When abnormal noise occurs in the cross roller slewing bearing, it is crucial to inspect the bearing for collisions or damage. If the bearing is found to be damaged, it must be replaced promptly. Even minor issues can significantly affect the operation of the bearing and lead to further damage if not addressed. Timely replacement of worn or damaged bearings ensures smooth operation and prevents unexpected breakdowns.

Regular inspections and preventive maintenance can help identify early signs of wear and allow for timely intervention. Using high-quality replacement bearings can also enhance the longevity and performance of the machinery.

If the clearance of the cross roller slewing bearing is too small, it can lead to increased friction and abnormal noise. Therefore, it is essential to check and adjust the clearance when abnormal noise is detected. Proper clearance ensures optimal load distribution and reduces the risk of excessive wear and noise.

Adjusting the clearance involves careful measurement and alignment to ensure the rollers have adequate space to move freely without causing excessive friction. This adjustment should be performed by trained technicians to avoid incorrect settings that could lead to further issues.

The selection and maintenance of lubricants are critical for the performance of bearings. Poor-quality lubricants can cause abnormal noise, increased wear, and operational inefficiency. Therefore, it is essential to use high-quality lubricants that meet the specific requirements of the CAT 330 7Y0933 Slew Ring Bearing.

Regular monitoring and timely replacement of the lubricant can prevent abnormal noise and extend the bearing’s lifespan. The lubricant should be checked for contamination, viscosity, and performance characteristics to ensure it provides adequate protection and lubrication.

Understanding the causes and solutions for abnormal noise in CAT 330 7Y0933 Slew Ring Bearings is essential for maintaining the performance and longevity of heavy machinery. Abnormal noise can be indicative of underlying issues such as bearing wear, incorrect clearance, foreign object contamination, or poor lubricant performance. By addressing these issues promptly and effectively, operators can ensure smooth and efficient operation, reducing downtime and maintenance costs.

Regular inspection, proper maintenance, and timely replacement of components are key to preventing abnormal noise and ensuring the optimal performance of slewing bearings. By following these best practices, operators can enhance the reliability and efficiency of their machinery, contributing to overall operational success.

Q1: What are the main causes of abnormal noise in CAT 330 7Y0933 Slew Ring Bearings?

A1: The main causes of abnormal noise in CAT 330 7Y0933 Slew Ring Bearings include bearing wear, small clearance between the shafts, foreign objects entering the bearing, and poor lubricant performance. Each of these issues can lead to increased friction, vibration pulses, and operational inefficiency.

Q2: How can bearing wear cause abnormal noise?

A2: Bearing wear can cause abnormal noise when the inner and outer raceways become damaged due to impact, operational faults, or general wear and tear. Surface defects such as scratches or dents on the rolling elements can lead to clear and crisp abnormal noises, indicating significant damage.

Q3: What is the importance of clearance in slewing bearings?

A3: Clearance in slewing bearings is crucial for optimal performance. Proper clearance ensures smooth operation by allowing adequate space for the rolling elements to move freely without causing excessive friction. Incorrect clearance can lead to increased friction, overheating, and abnormal noise.

Q4: How do foreign objects cause abnormal noise in bearings?

A4: Foreign objects such as dust, impurities, or iron filings can enter the bearing and cause severe friction with the rolling elements in the raceway. These contaminants generate periodic or non-periodic vibration pulses, leading to abnormal noise during operation and potential damage to the bearing.

Q5: Why is lubricant performance important for slewing bearings?

A5: Lubricant performance is critical for reducing friction and wear between the rolling elements and raceways. Poor-quality lubricants or inadequate lubrication can lead to increased friction, wear, and abnormal noise. Proper selection, monitoring, and replacement of lubricants are essential for maintaining optimal bearing performance.

Q6: What are the solutions for addressing abnormal noise in slewing bearings?

A6: Solutions for addressing abnormal noise in slewing bearings include timely replacement of worn or damaged bearings, adjusting the clearance to ensure proper load distribution, and using high-quality lubricants with regular monitoring and replacement. These measures help reduce friction, wear, and operational inefficiency.

By understanding and addressing the causes of abnormal noise in CAT 330 7Y0933 Slew Ring Bearings, operators can ensure smoother operation, enhanced performance, and longer lifespan for their machinery. Regular maintenance and proper care are essential for preventing issues and maintaining optimal efficiency.