Excavators are indispensable machines in various industries, from construction to mining, thanks to their ability to handle heavy loads and perform a range of tasks. One of the critical components of an excavator is the swing bearing, which allows the machine to rotate and maneuver efficiently. However, rulment de leagăn pentru excavator noise is a common issue that can indicate underlying problems and affect the overall performance of the excavator. In this blog, we will explore the causes of swing bearing noise, solutions for mitigating this noise, and the importance of timely replacement of the excavator final drive when necessary. By understanding these aspects, operators can ensure their excavators run smoothly and efficiently, minimizing downtime and maintenance costs.

Swing bearing noise can arise from several factors, each of which requires specific attention and intervention. Identifying the root cause of the noise is the first step towards implementing effective solutions. Here are some common causes of swing bearing noise:

Dust and other foreign particles can infiltrate the swing bearing, causing irregular and non-periodic noise. This type of noise is often unpredictable and can vary in intensity. Contaminants can enter the bearing through various means, including inadequate sealing or poor maintenance practices.

Cracks, indentations, or rust on the rolling surface of the swing bearing can lead to periodic vibrations and noise. This type of noise is usually consistent with the rotational speed of the bearing and can vary depending on installation and lubrication conditions.

Improper lubrication is a significant cause of bearing noise. This includes using the wrong type of lubricant, insufficient lubrication, or aged grease. Lubrication issues can lead to increased friction, heat, and ultimately noise.

Incorrect installation of the swing bearing can result in misalignment, uneven load distribution, and noise. Installation errors can occur due to improper handling, insufficient pre-tightening force, or failure to follow manufacturer guidelines.

In some cases, the noise generated by the swing bearing is related to the host machinery rather than the bearing itself. This can include issues such as motor axial vibration or frame resonance, which can cause the bearing to produce noise.

Addressing swing bearing noise involves a combination of preventive measures, proper maintenance practices, and timely interventions. Here are some effective solutions to mitigate swing bearing noise:

One of the primary methods to prevent dust-related noise is to improve the cleaning and maintenance practices for the swing bearing. This includes:

Using the correct type and amount of lubricant is crucial for preventing bearing noise. Consider the following lubrication practices:

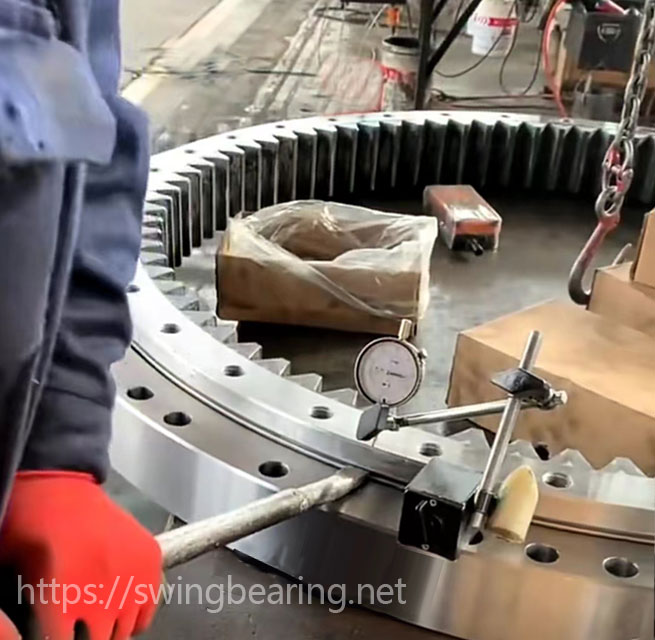

Proper installation of the swing bearing is essential to prevent noise and ensure smooth operation. Follow these guidelines for correct installation:

Sometimes, noise from the swing bearing is related to the host machinery. Addressing these issues can help reduce bearing noise:

The excavator final drive is another critical component that can impact the performance and noise levels of the machine. The final drive transfers power from the engine to the tracks, enabling the excavator to move. Over time, the final drive can wear out, leading to decreased performance and increased noise. Here’s why timely replacement of the excavator final drive is important:

A worn-out final drive can significantly impact the excavator’s performance. It can cause the machine to move slowly, lose power, and struggle with heavy loads. Replacing the final drive ensures that the excavator maintains optimal performance and can handle demanding tasks efficiently.

A damaged or worn final drive can produce noise, which can affect the overall operation of the excavator. Replacing the final drive can help reduce noise levels, making the machine operate more smoothly and quietly.

Continuing to operate an excavator with a worn-out final drive can cause additional damage to other components, leading to more extensive and costly repairs. Timely replacement of the final drive prevents further damage and extends the lifespan of the excavator.

A malfunctioning final drive can pose safety risks to the operator and other workers on the site. It can cause the excavator to become unstable or difficult to control. Replacing the final drive ensures the excavator operates safely and reliably.

Swing bearing noise in excavators is a common issue that can indicate underlying problems and affect the machine’s performance. By understanding the causes of swing bearing noise and implementing effective solutions, operators can ensure their excavators run smoothly and efficiently. Regular cleaning and maintenance, proper lubrication, correct installation techniques, and addressing host machinery issues are key to preventing noise-related problems.

Additionally, timely replacement of the excavator final drive is crucial for maintaining performance, reducing noise, preventing further damage, and ensuring safety. By paying attention to these aspects, operators can minimize downtime, reduce maintenance costs, and extend the lifespan of their excavators.

Q1: What are the common causes of swing bearing noise in excavators?

A1: Common causes of swing bearing noise in excavators include dust and contaminants, bearing damage, improper lubrication, installation errors, and host machinery factors such as motor axial vibration or frame resonance.

Q2: How can dust-related noise in swing bearings be prevented?

A2: Dust-related noise can be prevented by enhancing cleaning and maintenance practices, ensuring proper sealing, and regularly inspecting and replacing the lubricant to remove contaminants.

Q3: What are the proper lubrication practices to prevent bearing noise?

A3: Proper lubrication practices include selecting the right lubricant designed for swing bearings, ensuring sufficient lubrication, and regularly replacing aged grease with fresh lubricant to maintain optimal performance and reduce noise.

Q4: What are the guidelines for correct installation of swing bearings to prevent noise?

A4: Guidelines for correct installation include avoiding striking the bearing during installation, ensuring proper alignment, and applying sufficient pre-tightening force to the installation bolts using a torque wrench.

Q5: How can host machinery issues related to swing bearing noise be addressed?

A5: Host machinery issues related to swing bearing noise can be addressed by checking and adjusting the alignment of the motor shaft to prevent axial vibration, securing the motor mounting, and enhancing the design and material of the bearing frame to minimize resonance.

Q6: Why is it important to replace the excavator final drive?

A6: Replacing the excavator final drive is important to maintain performance, reduce noise, prevent further damage to other components, and ensure the safety of the operator and workers on the site.