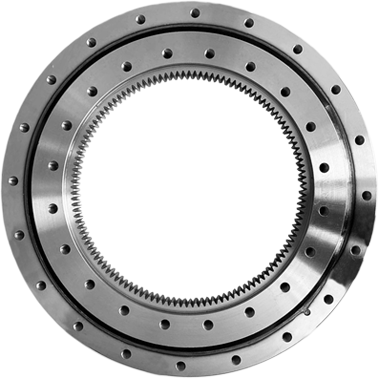

Swing bearings are a crucial component of excavators, especially in models like the Caterpillar E300 and E300B. These bearings facilitate the rotation of the excavator’s upper structure, ensuring smooth and efficient operation. In this detailed guide, we will explore the specifications, processing, precautions for use, and other related aspects of the Caterpillar Excavator E300, E300B Swing Bearing. This guide is designed to provide comprehensive information, ensuring that operators and technicians can maintain these components effectively.

The Caterpillar Excavator E300, E300B Swing Bearing is designed to replace several part numbers, including 096-1950, G54890700, 957708, and 942593. These bearings are specifically crafted to fit the E300 and E300B models, ensuring seamless integration and optimal performance.

Weighing in at 1030 lbs, these swing bearings are constructed to withstand the rigorous demands of heavy excavation work. The robust construction provides durability and reliability, essential for the efficient functioning of the excavator’s swing mechanism.

Swing bearings are typically made from high-quality alloy steel. This material is chosen for its strength, durability, and resistance to wear and fatigue. The steel must undergo rigorous quality checks to ensure it meets the required standards.

The first step in the manufacturing process involves cutting the raw steel into the appropriate size. Precision cutting tools are used to ensure accuracy. The cut pieces are then forged into billets, which are heated to improve malleability. Forging enhances the grain structure of the steel, making it more robust and capable of withstanding heavy loads.

The forged billets undergo rough turning to shape them into the basic form of the swing bearing. This process removes excess material and prepares the workpiece for more precise machining operations.

Precision grinding is a critical step in the manufacturing process. It ensures that the swing bearings achieve exact dimensions and a smooth surface finish. This precision is crucial for the bearing to function correctly within the excavator.

Heat treatment processes such as quenching and tempering are used to enhance the properties of the steel. Quenching hardens the steel, while tempering reduces brittleness and improves toughness. This dual process ensures that the bearings can withstand the demanding conditions of excavation work.

After machining and heat treatment, the inner and outer races, rolling elements, and seals are meticulously assembled. Each component is inspected and fitted to ensure optimal performance.

The completed swing bearings are subjected to rigorous inspection and testing. Any deviations from the specified standards are corrected to ensure that each bearing meets the highest quality requirements.

The finished swing bearings are securely packaged to protect them from damage during transit. This packaging ensures that the bearings arrive in perfect condition, ready for installation.

Our streamlined shipping process ensures that the swing bearings are delivered securely and on time. This minimizes downtime and keeps operations running smoothly.

Ensure that the swing bearing is correctly aligned and positioned during installation. Improper alignment can lead to uneven wear and premature failure.

Use a torque wrench to tighten the bolts securing the swing bearing. Over-tightening or under-tightening can compromise the integrity of the bearing.

Regular lubrication is essential for maintaining the performance of the swing bearing. Use the recommended lubricant and follow the manufacturer’s guidelines for lubrication intervals.

Inspect the seals regularly for signs of wear or damage. Replace any damaged seals promptly to prevent contamination and ensure the bearing operates smoothly.

Ensure that the excavator is not overloaded beyond its capacity. Excessive loads can cause undue stress on the swing bearing, leading to premature wear and failure.

Operate the excavator in a balanced manner, avoiding sudden or jerky movements. Smooth and controlled operation reduces stress on the swing bearing and extends its lifespan.

Conduct regular visual inspections to check for signs of wear, cracks, or deformation. Address any issues promptly to prevent further damage.

Test the swing bearing’s performance under normal working conditions. Look for signs of uneven movement or unusual noises, which can indicate underlying issues.

A: Key inspection points include visual checks for wear and damage, lubrication condition, bearing clearance measurement, seal integrity, and bolt tightness. Regular inspections help identify potential issues early and maintain the bearing’s performance.

A: It is recommended to conduct daily visual checks and more thorough inspections monthly or after every 500 hours of operation. Consistent inspections help in identifying and addressing potential issues early.

A: Essential tools include a torque wrench, grease gun, visual inspection tools (flashlight and mirror), cleaning supplies, and precision measuring tools such as calipers and micrometers.

A: Regular inspections, proper lubrication, timely replacement of seals and worn components, and ensuring that all bolts and fasteners are securely tightened are key practices for maintaining the longevity of the swing bearing.

A: If excessive play is detected, measure the bearing clearance and compare it to the manufacturer’s specifications. If the clearance exceeds acceptable limits, consider adjusting or replacing the bearing to restore proper function.

The swing bearings for Caterpillar E300 and E300B excavators are vital components that ensure smooth and efficient operation. Understanding their specifications, manufacturing process, and proper usage is essential for maintaining the performance and longevity of these bearings. Regular inspections and maintenance are crucial for preventing issues and ensuring the reliability of the excavator’s swing mechanism. By following the guidelines and precautions outlined in this guide, operators and technicians can effectively manage and maintain their swing bearings, minimizing downtime and maximizing operational efficiency.