When operating a Komatsu excavator, one of the most frustrating issues you can encounter is a significant slowdown in its movement. This problem can stem from various faults within the machine, each requiring timely and precise diagnosis to prevent further damage. Ignoring these issues can exacerbate them, leading to more severe and costly repairs. In this blog, we will delve into the common symptoms and reasons behind a slow-moving Komatsu excavator and the steps you should take to address them.

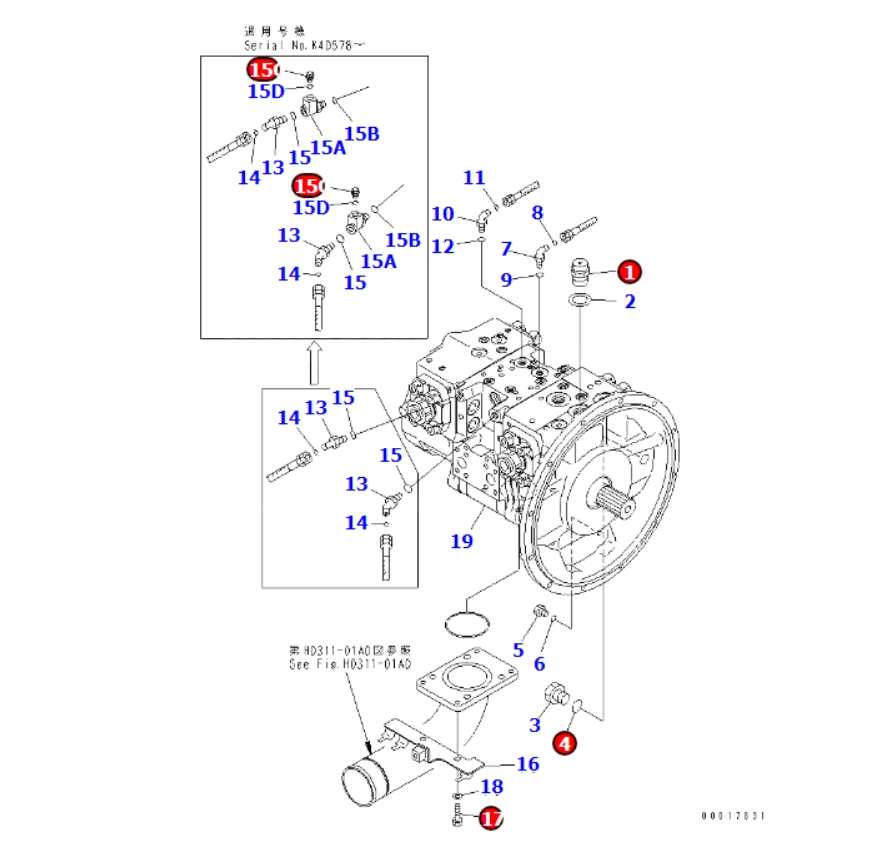

One of the primary reasons for an excavator’s slow movement is the severe wear of the hydraulic pump, which causes internal leakage. When the hydraulic pump components wear down, they can no longer maintain the required pressure, resulting in a decrease in hydraulic fluid flow and subsequently slowing down the machine’s operations.

Pressure abnormalities can significantly impact the excavator’s performance. It is crucial to check whether the hydraulic system’s pressure is within the normal range. If not, you may need to adjust the flow and torque of the pump and valve to restore proper functioning.

A damaged or poorly connected speed sensor can prevent the computer from receiving accurate signals, causing the electromagnetic proportional method to fail and slowing down the entire excavator. Ensuring the speed sensor is in good condition is essential for maintaining the correct speed of the machine.

The EPPR (Electro Proportional Pressure Reducing) valve of the main pump can also cause slow movement if there is an issue. Checking whether the EPPR valve pressure is too high can help identify and rectify the problem.

Slow movement often indicates insufficient hydraulic oil flow. This can be due to several factors such as the main pump swash plate being stuck at a small angle, the main pump being worn and leaking, dirty hydraulic oil, clogged oil return filters, or serious leakage in the control valve. Addressing these issues can help restore normal operation.

High hydraulic oil temperature can cause the oil to become thinner, leading to a drop in efficiency. If the oil pump is not functioning correctly or the pressure limiting valve is not sealing well, it can result in slow movement. Ensuring that the oil pump seal and pressure limiting valve are in good condition is critical.

During warm-up operations, a slow-moving excavator might indicate problems such as abnormal engine speed during hydraulic overflow, the presence of black smoke, or the engine being held back. For new vehicles, it’s essential to check the hydraulic filter element and fuel filter element. For older vehicles, it’s necessary to inspect the fuel pump’s working condition and the hydraulic pump’s flow rate.

A sudden slowdown in the excavator’s movement can be attributed to failures in the high-speed solenoid valve, hydraulic pump regulator, or excessively low pilot pressure. Identifying and addressing these failures promptly is crucial for maintaining the excavator’s efficiency.

A slow-moving Komatsu excavator can result from various complex issues involving precision parts. For experienced operators, diagnosing and handling these problems can still be challenging, and for novices, it can be overwhelming. To efficiently troubleshoot and resolve these issues, it is best to seek help from a professional excavator maintenance expert. Addressing the problem promptly can prevent further damage and ensure the excavator operates at peak performance.

Q1: Why does a severely worn hydraulic pump cause the excavator to move slowly?

A1: A severely worn hydraulic pump leads to internal leakage, which decreases the hydraulic fluid flow necessary for the machine’s operations. This reduced flow results in slower movement of the excavator.

Q2: How can pressure abnormalities affect the excavator’s performance?

A2: Pressure abnormalities can disrupt the hydraulic system’s functionality, causing the machine to operate inefficiently. Adjusting the flow and torque of the pump and valve can help restore the system’s pressure to normal levels.

Q3: What role does the speed sensor play in the excavator’s movement?

A3: The speed sensor provides critical signals to the computer for controlling the excavator’s speed. If the sensor is damaged or has poor contact, it can cause the machine to slow down by preventing the electromagnetic proportional method from activating correctly.

Q4: What should be checked if the EPPR valve of the main pump is suspected to be faulty?

A4: If the EPPR valve is suspected to be faulty, you should check whether its pressure is too high. Correcting the pressure can help resolve slow movement issues.

Q5: Why does high hydraulic oil temperature cause slow movement?

A5: High hydraulic oil temperature can thin the oil, reducing its effectiveness. This can cause the oil pump to work less efficiently and the pressure limiting valve to not seal properly, leading to slow movement of the excavator.

Q6: What should be done if the excavator shows slow movement during warm-up operations?

A6: If the excavator shows slow movement during warm-up operations, check whether the engine speed is normal during hydraulic overflow, inspect for black smoke, and determine if the engine is being held back. Additionally, check the hydraulic filter element and fuel filter element for new vehicles, and for older vehicles, examine the fuel pump’s working condition and the hydraulic pump’s flow rate.

Q7: What could cause a sudden slowdown in the excavator’s movement?

A7: A sudden slowdown in the excavator’s movement can be caused by failures in the high-speed solenoid valve, hydraulic pump regulator, or excessively low pilot pressure. Identifying and addressing these issues promptly is essential for restoring normal operation.

By understanding and addressing these common issues, you can prevent slow movement in your Komatsu excavator and ensure it operates smoothly and efficiently. Seeking professional help when needed is crucial for maintaining the machine’s performance and longevity.