Excavators are essential machinery in construction and mining operations. When an excavator experiences traveling issues, it can significantly hinder productivity and efficiency. This blog will delve into the common causes of excavator traveling issues and provide detailed methods for troubleshooting and resolving these problems.

One frequent cause of traveling issues is the presence of contaminants in the parking brake circuit’s balance valve. When foreign particles block the small orifices in the balance valve, the parking brake cannot be disengaged, leading to traveling deviations. During operation, if hydraulic pressure cannot move the balance valve spool due to blockage, the hydraulic system cannot release the parking brake, causing the travel motor to malfunction.

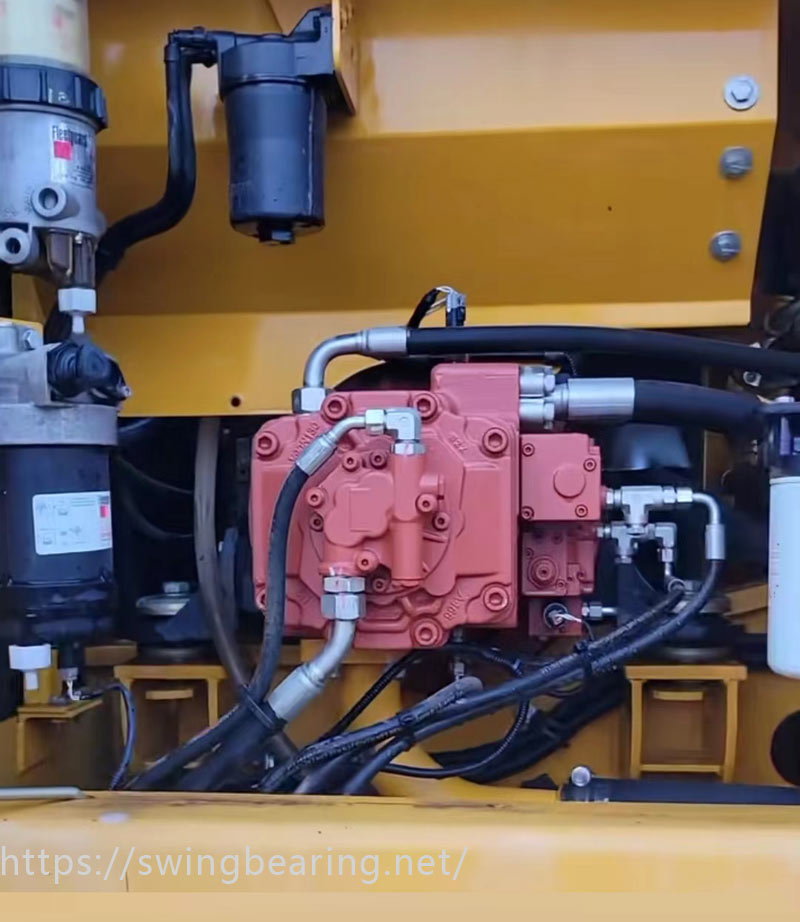

The center swivel joint, comprising a housing and spindle, plays a crucial role in maintaining hydraulic fluid flow between the upper and lower parts of the excavator. If the hydraulic oil filter is not replaced timely, contaminants can damage the seals of the swivel joint. This can lead to uneven pressure distribution between the travel motors, causing traveling issues.

Similar to the parking brake circuit issue, contaminants can also block the small orifices in the final drive system’s balance valve, preventing the release of the parking brake and causing traveling issues.

A leaking relief valve in the travel motor can cause low system pressure, resulting in insufficient travel motor speed and traveling issues.

The travel proportional valve controls the speed and direction of the excavator’s travel motors based on joystick input. If the filter is clogged and the bypass valve opens, unfiltered hydraulic oil can cause the proportional valve to malfunction.

The travel suction valve, located on the hydraulic cylinder and motor, helps protect the system from external shocks by relieving excessive pressure. If the valve is damaged, it can result in low oil pressure in the travel main valve, causing insufficient travel motor power.

A malfunctioning travel main valve spool, whether due to a weakened or broken spring or a jammed spool, can lead to reduced hydraulic pressure and traveling issues.

Visuelle Inspektion: Start with a thorough visual inspection of the excavator. This step is crucial because many issues can be identified through a simple visual check. Look for any signs of wear, cracks, or leaks in the hydraulic hoses, connectors, and cylinders. Hydraulic oil leaks not only lead to a drop in hydraulic system pressure but also cause environmental contamination and potential equipment damage. Additionally, check the tracks and drive wheels for any visible wear or damage. Ensure that the track tension is appropriate, as tracks that are too loose or too tight can affect the excavator’s traveling performance.

Operational Test: After the visual inspection, start the excavator and observe its actual operation. By operating the excavator, pay attention to which side of the tracks is lagging or malfunctioning. Specifically, you can determine which track has issues by performing basic operations such as moving forward, backward, turning left, and turning right. If one side of the track is sluggish or completely unresponsive, it may indicate problems in the hydraulic system or mechanical components.

Check Hydraulic Oil and Filters: The normal operation of the hydraulic system depends on clean hydraulic oil and effective filters. First, check the hydraulic oil level to ensure it is within the recommended range; if it is low, add the appropriate type of hydraulic oil. Next, examine the color and condition of the hydraulic oil; it should be clear. If the oil has changed color or contains contaminants, it needs to be replaced. Finally, check the hydraulic filters to ensure they are not clogged. If the filters are blocked, replace them to ensure smooth oil flow.

Inspect Valves: The balance valve, proportional valve, and relief valve are critical to the proper functioning of the hydraulic system. First, inspect the balance valve to ensure it is working correctly, as a faulty balance valve can cause system imbalances, affecting the excavator’s traveling performance. Next, check the proportional valve, as a malfunctioning proportional valve can lead to uneven hydraulic oil flow, impacting the driving force of the tracks. Finally, inspect the relief valve, as a faulty relief valve can cause abnormal system pressure, affecting the overall operation of the hydraulic system.

Pressure Testing: To further pinpoint the issue, conduct pressure testing on different parts of the hydraulic system. Use a pressure gauge to measure the pressure in the hydraulic system and compare the test results with the manufacturer’s standard pressure values to identify any discrepancies. Pressure testing helps determine if there are faults in the hydraulic pump, hydraulic motor, or hydraulic lines.

Valve Swapping: To identify if the valves are faulty, try swapping the valves between the left and right sides. If the problem moves to the other side along with the valve, it indicates a faulty valve that needs replacement or repair. If the problem does not move with the valve, further inspection of other hydraulic system components or mechanical parts is necessary.

Clean Contaminated Parts: If any parts are found to be contaminated during the previous checks, they need to be thoroughly cleaned. Use professional cleaning agents and tools to remove contaminants from valves, pipelines, and other hydraulic system components, ensuring smooth hydraulic oil flow.

Replace Damaged Components: For components that are damaged or severely worn, replacement is necessary. When replacing hydraulic seals, valves, or other damaged parts, ensure you use original or qualified substitutes to guarantee the system’s proper functioning. Avoid using low-quality parts to prevent further damage.

Reassemble Components: After cleaning and replacement, carefully reassemble all parts. Make sure no new contaminants are introduced during reassembly, and secure all connections tightly to prevent looseness and leaks.

Operational Test: Finally, start the excavator and perform a comprehensive operational test. By moving forward, backward, turning left, and turning right, confirm the issue has been resolved. If the excavator travels normally, the problem has been fixed. If the issue persists, further inspection of the hydraulic system or other mechanical components may be required.

Traveling issues in excavators can arise from a variety of causes, including contaminants in the hydraulic system, damaged seals, and malfunctioning valves. By understanding these common issues and following a systematic troubleshooting approach, operators can effectively diagnose and resolve traveling problems, ensuring that their excavators operate smoothly and efficiently.

Regular maintenance, including timely replacement of hydraulic oil and filters, is crucial in preventing many of these issues. By staying vigilant and proactive, operators can minimize downtime and keep their excavators running at peak performance.

Answer: To diagnose a hydraulic pump issue, you can:

Answer: Potential causes of hydraulic pump failure include:

Answer: To prevent hydraulic pump failure, you can:

Answer: If you suspect a hydraulic pump failure, you should: