When operating an excavator, one of the most frustrating issues that can arise is a noisy hydraulic final drive. This noise not only disrupts the work environment but can also indicate a potential problem with the machine’s performance. In this article, we will discuss the various causes of noise in hydraulic final drives and provide some troubleshooting tips to help you identify and resolve the issue.

First and foremost, it is essential to understand the components of a hydraulic final drive system. The final drive is responsible for transmitting power from the engine to the wheels or tracks of the excavator. This power is transmitted through a series of gears, bearings, and seals, all of which can contribute to noise if they become worn or damaged.

One common cause of noise in a hydraulic final drive is worn or damaged bearings. As the bearings support the movement of the gears within the final drive, any wear or damage can cause friction and generate noise. To troubleshoot this issue, you should inspect the bearings for signs of wear, such as pitting or scoring. If you find any damaged bearings, they should be replaced as soon as possible to prevent further damage to the final drive system.

Another potential cause of noise in a hydraulic final drive is a leak in the system. Leaks can occur due to damaged seals or gaskets, which can allow hydraulic fluid to escape from the system. This fluid loss can cause the final drive to operate less efficiently, leading to increased noise levels. To troubleshoot this issue, you should inspect the seals and gaskets for any signs of damage or wear. If you find any leaks, they should be repaired or replaced to restore the integrity of the hydraulic system.

In addition to worn or damaged components, noise in a hydraulic final drive can also be caused by contamination of the hydraulic fluid. Contaminants such as dirt, debris, or water can enter the system and cause abrasive wear on the components, leading to increased noise levels. To troubleshoot this issue, you should check the hydraulic fluid for signs of contamination, such as discoloration or a change in viscosity. If you find any contamination, the fluid should be drained and replaced with clean, high-quality hydraulic fluid.

Another potential cause of noise in a hydraulic final drive is misalignment of the components. Misalignment can cause increased friction and wear on the gears and bearings, leading to increased noise levels. To troubleshoot this issue, you should inspect the alignment of the final drive components, ensuring that they are properly aligned and securely fastened. If you find any misalignment, it should be corrected to reduce wear and noise.

Lastly, it is essential to consider the operating conditions of the excavator when troubleshooting noise in a hydraulic final drive. Operating the machine in extreme temperatures or on rough terrain can cause increased wear on the components, leading to increased noise levels. To troubleshoot this issue, you should ensure that the excavator is operated under optimal conditions, such as on level terrain and at appropriate temperatures.

In conclusion, troubleshooting a noisy hydraulic final drive in an excavator requires a thorough understanding of the components and operating conditions of the machine. By inspecting the bearings, seals, and alignment of the final drive system, as well as the quality of the hydraulic fluid, you can identify and resolve the issue, ensuring smooth and quiet operation of your excavator.

A noisy hydraulic final drive in an excavator can be a source of frustration for operators and a potential indication of underlying issues that need to be addressed. In this article, we will discuss the common causes of noise in hydraulic final drives and provide guidance on how to troubleshoot and repair these problems.

Firstly, it is important to understand the components of a hydraulic final drive system. The final drive is responsible for transmitting power from the engine to the tracks or wheels of the excavator. This power is transmitted through a series of gears, bearings, and seals, all of which can contribute to noise if they become worn or damaged.

One common cause of noise in a hydraulic final drive is worn or damaged gears. Over time, the constant movement of the gears can cause them to wear down, leading to a grinding or scraping sound. This noise can be particularly noticeable when the excavator is in motion, as the gears are constantly engaged. To troubleshoot this issue, it is important to inspect the gears for signs of wear or damage. If the gears appear to be worn, they may need to be replaced or repaired.

Another potential cause of noise in a hydraulic final drive is damaged bearings. Bearings are responsible for supporting the movement of the gears and other components within the final drive system. Over time, the bearings can become worn or damaged, leading to a grinding or rumbling noise. To troubleshoot this issue, it is important to inspect the bearings for signs of wear or damage. If the bearings appear to be damaged, they may need to be replaced.

Seals are another important component of a hydraulic final drive system. Seals are responsible for preventing the leakage of hydraulic fluid from the system, which can lead to a loss of power and increased noise. Over time, the seals can become worn or damaged, leading to a hissing or bubbling noise. To troubleshoot this issue, it is important to inspect the seals for signs of wear or damage. If the seals appear to be damaged, they may need to be replaced.

In addition to inspecting the individual components of the hydraulic final drive system, it is also important to consider the overall condition of the system. For example, if the final drive system is overloaded or operating at an excessive speed, this can lead to increased noise and potential damage to the components. To troubleshoot this issue, it is important to ensure that the excavator is being operated within its recommended load and speed limits.

Once the source of the noise has been identified, it is important to take appropriate action to repair the problem. This may involve replacing worn or damaged components, such as gears, bearings, or seals. In some cases, it may also be necessary to adjust the settings of the final drive system, such as the load and speed limits, to prevent further damage.

In conclusion, troubleshooting a noisy hydraulic final drive in an excavator involves a thorough inspection of the individual components of the system, as well as consideration of the overall condition of the system. By identifying the source of the noise and taking appropriate action to repair the problem, it is possible to restore the performance and longevity of the final drive system and prevent further damage.

A noisy hydraulic final drive in an excavator can be a significant source of disruption and frustration for operators and those working in close proximity to the machine. The noise generated by a faulty final drive can not only be irritating but may also indicate underlying issues with the hydraulic system that require immediate attention. In this article, we will discuss the various causes of noise in hydraulic final drives and provide some troubleshooting tips to help you identify and resolve the problem.

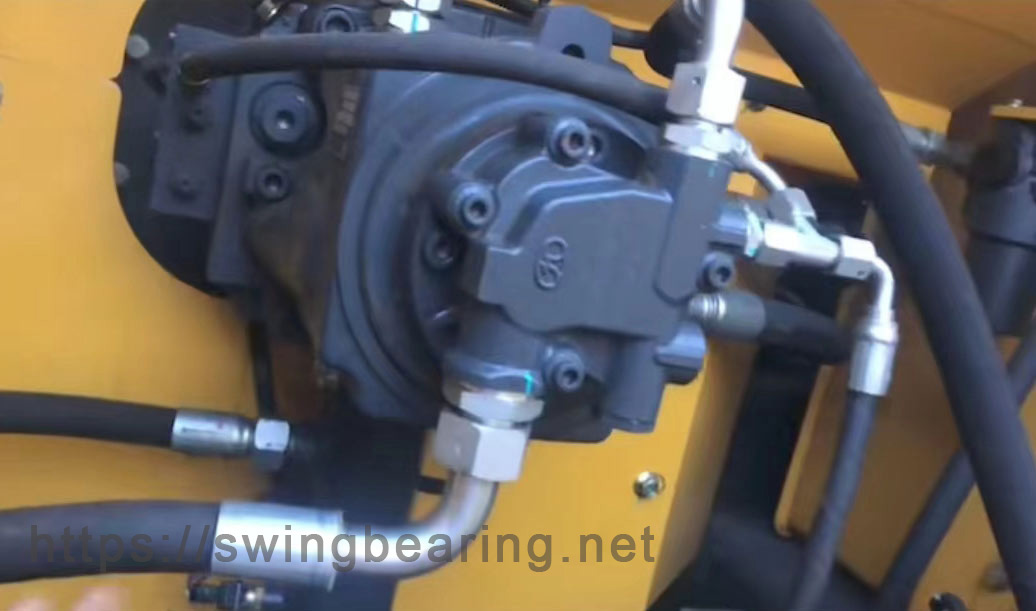

First and foremost, it is essential to understand the components of a hydraulic final drive system. The final drive is responsible for transmitting power from the engine to the wheels or tracks of the excavator. It consists of a pump, motor, valves, and various seals and gaskets. When any of these components become worn or damaged, it can lead to excessive noise and reduced performance.

One common cause of noise in a hydraulic final drive is air leaks. Air leaks can occur due to worn seals, damaged hoses, or loose connections. When air enters the hydraulic system, it can cause cavitation, which is the formation of vapor bubbles in the fluid. As these bubbles collapse, they produce a knocking or hammering sound. To troubleshoot air leaks, inspect all seals, hoses, and connections for signs of wear or damage. Replace any worn components and tighten loose connections to eliminate the source of the noise.

Another potential cause of noise in a hydraulic final drive is contamination of the fluid. Dirt, debris, and other contaminants can enter the system and cause wear on the components, leading to increased noise levels. To prevent contamination, always use clean hydraulic fluid and change it regularly according to the manufacturer’s recommendations. Additionally, inspect the fluid filters and replace them as needed to maintain a clean and efficient system.

Worn or damaged components within the final drive itself can also contribute to noise. For example, worn gears can produce a grinding or scraping sound as they interact with one another. Similarly, damaged bearings can cause a rumbling or grinding noise as they wear down and lose their ability to support the load. To identify worn components, perform a thorough inspection of the final drive assembly. Look for signs of wear, such as scoring or pitting on gears, and replace any damaged components to restore smooth operation.

In some cases, noise in a hydraulic final drive may be caused by an imbalance in the system. This can occur if one component is not functioning correctly or if there is an issue with the alignment of the final drive components. To troubleshoot an imbalance, check for any signs of uneven wear or damage on the components and ensure that all parts are properly aligned and functioning correctly.

In conclusion, troubleshooting a noisy hydraulic final drive in an excavator requires a thorough understanding of the system and its components. By identifying the cause of the noise and addressing any issues with air leaks, contamination, worn components, or imbalance, you can restore the performance and noise-free operation of your excavator’s final drive. Regular maintenance and inspection of the hydraulic system will help prevent future issues and ensure a smooth, quiet operation for your excavator.

A hydraulic final drive is a component in heavy machinery that converts hydraulic energy into mechanical motion, powering the machine’s tracks or wheels.

A hydraulic final drive uses hydraulic fluid pressure to create rotational motion, which drives the machine’s tracks or wheels.

Common types include radial piston motors, axial piston motors, gerotor motors, vane motors, and screw motors, each with unique features and applications.