Excavator swing bearings, also known as turntable bearings, play a vital role in the smooth operation of heavy machinery, providing support for the rotational components. However, issues such as abnormal noise can compromise performance and signal potential mechanical failures. In this article, we explore the key causes of noise in excavator swing bearings and offer practical solutions to prevent these issues, ensuring long-term reliability and efficiency in demanding work environments.

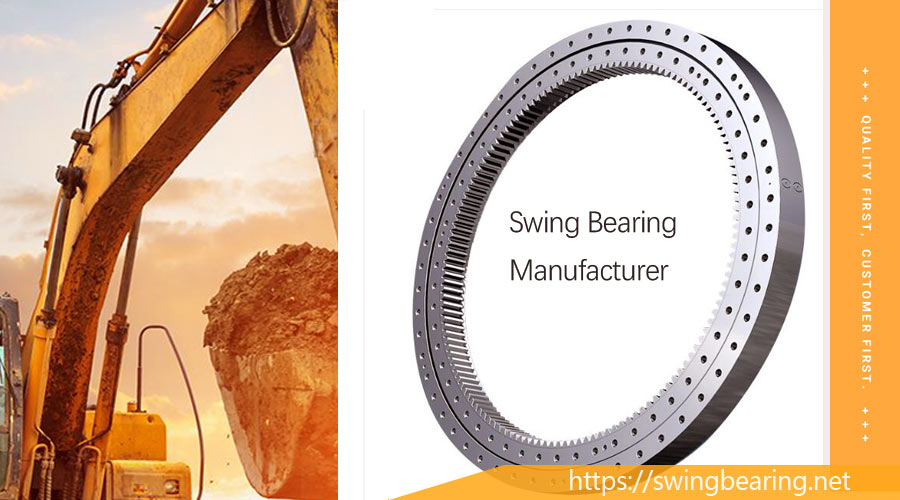

The excavator swing bearing, often called a turntable bearing, is a robust component designed to withstand significant axial, radial, and overturning loads. Equipped with mounting holes, gears (internal or external), lubrication points, and sealing mechanisms, the swing bearing is integral to the seamless operation of the excavator’s slewing system. It enables the upper structure of the machine to rotate, distributing heavy loads effectively while maintaining smooth, precise movement.

In some cases, excavator operators notice unusual noise coming from the swing bearing. While a uniform rolling noise during initial idle operation is typical, persistent or abnormal sounds indicate a problem that requires immediate attention. Below are five key reasons why an excavator swing bearing may produce noise and how to address these issues effectively.

An uneven mounting surface or improperly tightened bolts can significantly impact the performance of the excavator swing bearing. If the mounting surface does not meet the required flatness, it can cause the bearing raceway to experience negative clearance, leading to abnormal noise.

Table 1: Installation Checklist for Excavator Swing Bearings

| Issue | Inspection Method | Recommended Action |

|---|---|---|

| Uneven Mounting Surface | Use a precision level tool | Resurface or adjust the mounting area |

| Palaidi varžtai | Torque wrench inspection | Retighten to specified torque values |

| Poor Pinion Meshing | Visual and alignment check | Realign pinion and gear system |

Foreign particles like sand, dirt, or metal shavings inside the excavator swing bearing can cause irregular vibrations and obstruct smooth operation. This often leads to scratching or denting of the bearing surfaces, resulting in non-periodic noise.

If abnormal noise persists due to contamination, disassemble the bearing, clean all components meticulously, and reassemble with fresh, high-quality lubricant.

Proper lubrication is crucial for the efficient operation of excavator swing bearings. Inadequate or incorrect lubrication can result in increased friction, leading to noise and potentially severe damage.

Selecting the correct lubricant is essential to minimize noise and maximize bearing life. Consider factors like operating temperature, load capacity, and environmental conditions when choosing a grease.

Cracks, indentations, and rust on the raceway surface or rolling elements can lead to periodic vibrations and abnormal noises. These defects often arise from improper handling during installation or exposure to harsh environmental conditions.

Over time, heavy loads and frequent use can cause wear and tear on the raceway and rolling elements of the swing bearing. Excessive wear leads to increased play, reduced accuracy, and abnormal noise during operation.

Table 2: Common Causes and Solutions for Excavator Swing Bearing Noise

| Cause | Symptom | Recommended Action |

|---|---|---|

| Uneven Mounting Surface | Abnormal noise, vibration | Resurface, tighten bolts |

| Foreign Objects | Irregular noise, rough motion | Clean and re-lubricate |

| Insufficient Lubrication | Increased friction, noise | Re-lubricate, use high-quality grease |

| Surface Damage | Periodic noise, vibration | Repair or replace damaged parts |

| Severe Wear | Grinding noise, play | Inspect and replace as needed |

Abnormal noise can be caused by uneven installation surfaces, foreign objects, insufficient lubrication, surface damage, or severe wear. Identifying the source of the noise is crucial for proper maintenance.

The lubrication interval depends on the operating conditions. In general, it is recommended to lubricate the swing bearing every 200 working hours or as specified by the manufacturer.

Minor surface damage can sometimes be repaired, but severe cracks or wear often require a complete bearing replacement to ensure safe operation.

Conclusion:

Excavator swing bearings are subjected to heavy loads and harsh operating environments, making them prone to noise issues. By understanding the common causes and implementing effective preventive measures, you can extend the service life of the bearing and maintain the efficient operation of your equipment. Regular inspections, proper installation, and consistent lubrication are key to preventing noise and ensuring the reliability of your excavator’s slewing system.