Slewing bearings are integral components in heavy machinery, enabling smooth rotational movement and handling substantial loads. These bearings can be equipped with either external or internal gears, while some models are gearless, depending on the application requirements. Slewing bearing gears, mainly composed of spur gears, offer significant advantages by eliminating the need for additional drive gears, thereby saving time and cost in the design and manufacturing process. Typically, these gears range in modules from 4 to 24, but variations can exist to meet specific needs, including metric modules for particular applications. This article delves into the intricacies of slewing bearing gears, their design, manufacturing processes, and applications.

Slewing bearings equipped with gears are crucial for machinery that requires precise rotational movement and high load-bearing capacity. The gears facilitate seamless integration into various mechanical systems, ensuring efficient power transmission and operational stability. These gears are typically spur gears, known for their straightforward design and effective performance in transmitting motion and force between parallel shafts.

The primary advantage of incorporating gears into slewing bearings is the elimination of the need for additional drive gears. This integration simplifies the overall mechanical design, reduces assembly time, and lowers production costs. Furthermore, the gears enhance the load-bearing capabilities of the slewing bearings, making them suitable for heavy-duty applications in construction, mining, and industrial machinery.

Before manufacturing, slew bearing gears are meticulously designed and calculated according to customer specifications. Factors such as load capacity, operational environment, and application-specific requirements are considered. The load capacity of the gears is determined based on DIN or ISO standards, ensuring reliability and performance. Additionally, related pinions can be designed and manufactured to match the gears, providing a comprehensive solution from a single source.

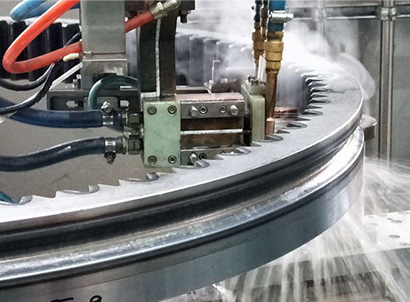

In applications where exceptionally high service life is required, the teeth of the slew bearing gears are hardened through a quenching process. Hardening enhances the wear resistance and durability of the gears, allowing them to withstand higher loads and prolonged operational cycles. However, it is essential to recalculate the load capacity when using hardened gears to ensure they meet the specific application requirements.

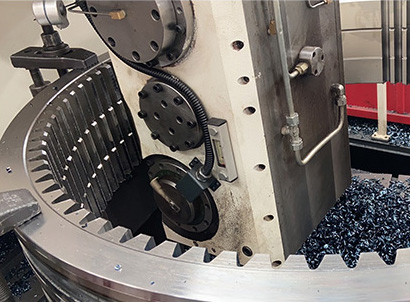

The manufacturing process of slewing bearing gears involves technical limitations that can lead to deviations in gear tooth profiles. These deviations must be accounted for during assembly to ensure proper alignment and clearance. Typically, slewing bearings with gears have an axial clearance that must be adjusted during installation. The highest point of the radial run-out of the gear is marked with three green teeth, indicating the exact location for adjusting and controlling tooth clearance. When multiple pinions are involved, each pinion must be adjusted to achieve the same clearance state, ensuring synchronized operation.

Slewing bearing gears are critical components that enhance the functionality and efficiency of heavy machinery. Their ability to integrate seamlessly into mechanical systems, combined with the advantages of simplified design and cost savings, makes them indispensable in various industrial applications. By understanding the design, customization, and technical considerations involved in slewing bearing gears, manufacturers can ensure optimal performance and reliability in their machinery.

What are slewing bearing gears?

Slewing bearing gears are integral components of slewing bearings, typically composed of spur gears, that facilitate rotational movement and high load-bearing capacity in heavy machinery.

What are the advantages of using slewing bearing gears?

The main advantages include simplified mechanical design, reduced assembly time, lower production costs, and enhanced load-bearing capabilities, making them suitable for heavy-duty applications.

How are slewing bearing gears designed and customized?

Slewing bearing gears are designed based on customer specifications, considering factors like load capacity and operational environment. The design ensures reliability and performance according to DIN or ISO standards.

Why is hardening important for slewing bearing gears?

Hardening increases the wear resistance and durability of the gears, allowing them to withstand higher loads and extended operational cycles, which is essential for applications requiring high service life.

What are the different types of slewing bearing gears?

The types include no gear (for applications preferring external driving mechanisms), external gear (located on the outer edge for easy access), and internal gear (situated within the inner circumference for compact designs).