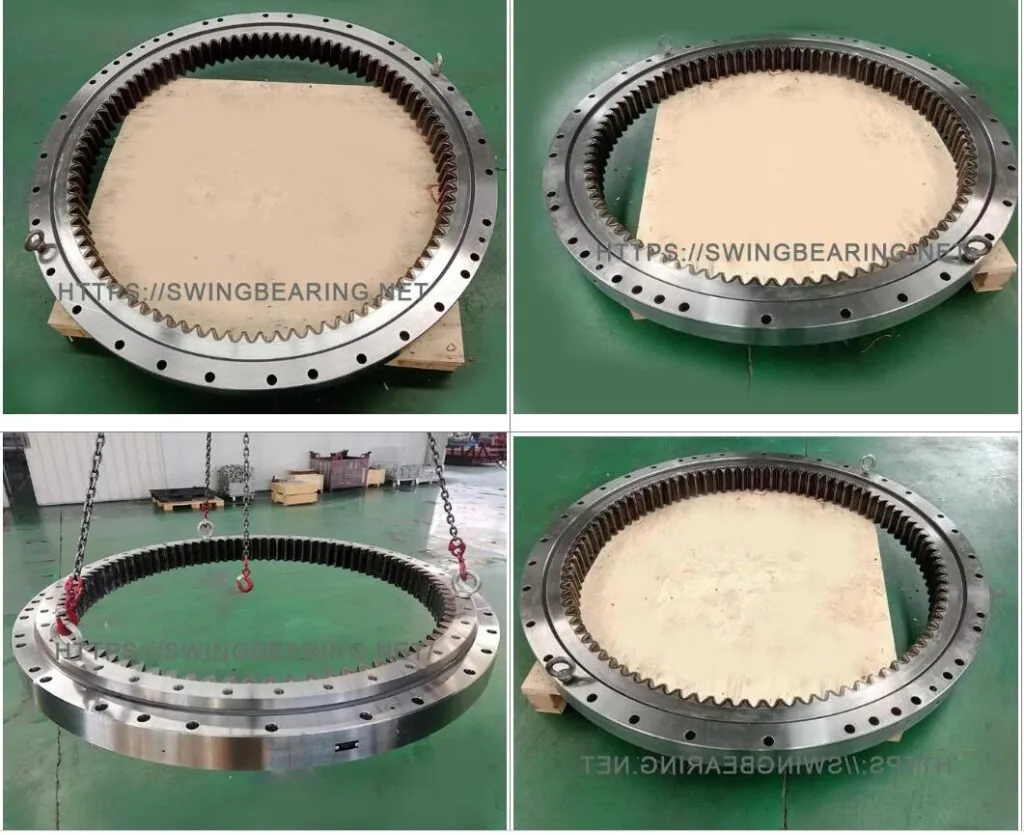

Slewing bearings are critical components in heavy machinery like the CAT 349D excavator. Ensuring smooth rotation and efficient operation is vital for the longevity and performance of your equipment. However, these components can encounter several issues during their lifecycle. This blog delves into the common problems with slewing bearing CAT 349D 353-0490, specifically model 353-0490, providing detailed troubleshooting steps and preventive measures.

Slewing bearings, such as the CAT 349D 353-0490, are designed to support axial loads, radial loads, and tilting moments. Despite rigorous inspections and trial operations before they leave the factory, slewing bearings can still face operational challenges. Understanding and addressing these issues is crucial for maintaining the efficiency and longevity of your machinery. This article explores common problems such as lack of rotational flexibility, unusual noises, and swinging, and offers detailed troubleshooting steps and resolutions.

Slewing bearings are designed to rotate smoothly. If you experience stiffness in the rotation, it can be attributed to various factors. Here’s a detailed guide to diagnosing and resolving this issue.

If a newly purchased slewing bearing exhibits stiffness, consider its production and storage conditions.

If stiffness occurs after installation, it may result from improper mounting or alignment issues.

Operational stiffness during use can indicate insufficient lubrication or damage to sealing strips.

If the slewing bearing fails to rotate smoothly after taking the above measures, it may indicate internal faults in the raceway.

Unusual noises during operation can signal potential issues within the slewing bearing. Identifying and resolving these noises is crucial for preventing further damage.

Slight noises during idle rotation of new products are generally normal and should disappear after several dozen rotations.

If abnormal noises occur during trial operation after assembly, check the mounting surface and gear meshing conditions.

Noises during use can result from insufficient lubrication, foreign objects in the raceway, or loose installation bolts.

Swinging in the slewing bearing after loading can indicate loose installation bolts or excessive clearance.

Troubleshooting common issues with slewing bearings, such as rotational stiffness, unusual noises, and swinging, is essential for maintaining the efficiency and longevity of your excavator. By following the detailed steps outlined in this blog, you can address these issues promptly and effectively. Regular maintenance and timely intervention can significantly enhance the performance and lifespan of your slewing bearings.

A: Stiffness in a new slewing bearing can be due to viscous lubricating grease, especially if stored for over six months in cold climates. Applying additional force during rotation can help achieve smooth operation. If abnormal noises persist, inspect for transportation damage and contact the manufacturer.

A: Ensure the mounting surface is re-machined to meet specifications or use shimming for adjustment. Adjust the gear clearance to minimize backlash and check for foreign objects in the gear meshing positions. Proper alignment and clearance adjustment are crucial for smooth operation.

A: Check the flatness of the mounting surface and ensure it meets specifications. Adjust the gear meshing conditions to eliminate intermittent tightness and looseness. If noises persist, contact the manufacturer for further assistance.

A: Swinging can result from loose installation bolts or excessive clearance. Ensure all inner and outer ring installation bolts are securely tightened and maintain proper clearance adjustments to prevent swinging during operation.

By addressing these common issues and following proper maintenance practices, you can ensure the optimal performance and longevity of your CAT 349D slewing bearings, enhancing the overall efficiency of your excavators.