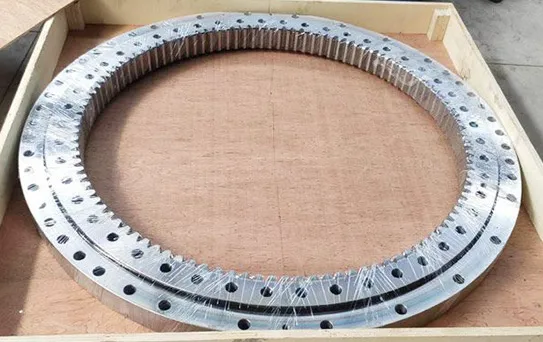

Swing bearings are integral components in heavy machinery, responsible for facilitating rotation and bearing substantial loads. The CAT 345B 136-2969 Swing Bearing, in particular, plays a crucial role in the efficient operation of various industrial equipment. Given its importance, identifying faults early is essential to prevent machinery downtime and costly repairs. In this blog, we will delve into the methods used to detect faults in CAT 345B 136-2969 Swing Bearings and explore factors affecting their load distribution.

One of the primary methods for identifying faults in double row ball slewing bearings is through voice recognition. During normal operation, the bearing should emit a slight, consistent noise. If a loud or unusual noise is detected, it indicates a potential issue. This could be due to wear or damage within the bearing. Once the source of the noise is identified and confirmed, the bearing raceway should be inspected and replaced if necessary to restore normal function.

Regularly checking the working temperature of the CAT 345B 136-2969 Swing Bearing is another effective fault detection method. A significant rise in temperature often signals a problem within the bearing, such as insufficient lubrication or internal friction. Monitoring the temperature allows for early detection of issues, enabling timely intervention and maintenance.

The condition of the lubricant within the bearing can provide valuable insights into its health. Regularly cleaning the double row ball slewing bearing and collecting samples of the lubricant for inspection can help identify the presence of dirt or metal particles. If contaminants are found, it indicates wear or damage within the bearing, necessitating cleaning or replacement to prevent further deterioration.

The CAT 345B 136-2969 Swing Bearing is designed to handle high loads, making it indispensable in various industrial applications. However, its load capacity is influenced by several factors, with load distribution being a critical aspect. Understanding these factors is essential for optimizing the bearing’s performance.

The load distribution within the bearing is significantly impacted by the initial contact angle and the radius factor. Establishing a single ball rolling contact model helps analyze how these factors affect the axial bearing capacity. This analysis is crucial for understanding the bearing’s performance under different load conditions and optimizing its design for specific applications.

An overall model of the bearing under composite load conditions is necessary to analyze the influence of various factors, such as the thickness of the ring wall and the number of steel balls, on load distribution. This comprehensive analysis helps in designing bearings that can efficiently handle complex load scenarios, ensuring reliability and durability.

With advancements in production technology and stringent management practices, the application market for bearings has expanded significantly. The use of precise manufacturing methods ensures accurate matching of lubricants and operational processes, leading to optimal efficiency and performance.

In double-row spherical rotating supports, four-point contact ball bearings play a pivotal role. Under conditions of no load and pure radial load, the steel ball contacts the circular ring at four points. When subjected to pure axial load, the ball contacts the ring at two points, allowing it to bear bi-directional axial loads. This versatility makes it a crucial component in various engineering machinery applications.

Bu CAT 345B 136-2969 Swing Bearing is a fundamental component in engineering machinery, praised for its load-bearing capabilities and robust performance. Identifying faults early through voice recognition, temperature monitoring, and lubricant inspection can significantly extend the bearing’s lifespan and maintain its efficiency. Understanding the factors affecting load distribution further enhances its application across diverse industries. As a professional manufacturer and supplier of slewing bearings, we are committed to providing high-quality solutions that meet the evolving needs of our customers.

Q1: Why is voice recognition important for identifying faults in CAT 345B 136-2969 Swing Bearings?

A1: Voice recognition helps detect unusual noises that indicate potential issues within the bearing. A slight, consistent noise is normal, but a loud or unusual noise suggests wear or damage that needs attention.

Q2: How does temperature monitoring help in fault detection?

A2: Monitoring the working temperature of the bearing allows for early detection of problems such as insufficient lubrication or internal friction, which often cause a rise in temperature.

Q3: What can lubricant inspection reveal about the bearing’s condition?

A3: Regularly inspecting the lubricant can identify the presence of dirt or metal particles, indicating wear or damage within the bearing. This allows for timely cleaning or replacement to prevent further issues.

Q4: What factors affect the load distribution in CAT 345B 136-2969 Swing Bearings?

A4: The initial contact angle, radius factor, thickness of the ring wall, and the number of steel balls all influence the load distribution within the bearing. Understanding these factors is essential for optimizing bearing performance.

Q5: How does technology and manufacturing impact bearing performance?

A5: Advanced production technology and precise manufacturing methods ensure accurate matching of lubricants and operational processes, leading to optimal efficiency and performance in various applications.