Excavators are remarkable machines used in various industries, from construction to mining. Their efficiency and versatility largely depend on the ability to smoothly rotate their upper structure. This critical function is made possible by a component known as the svänglager. In this blog, we’ll delve into how the swing bearing facilitates the rotation of an excavator’s upper structure, exploring its design, functionality, maintenance, and the challenges it faces. By the end, you’ll have a comprehensive understanding of this vital component and its role in the seamless operation of excavators.

The swing bearing, also known as a slewing ring or Lager för skivspelare, is a pivotal component in an excavator that enables the upper structure to rotate 360 degrees on its base. This rotation is crucial for the excavator’s functionality, allowing the operator to move the boom and attachment in any direction without repositioning the entire machine. The swing bearing not only supports the weight of the upper structure but also ensures smooth, precise, and reliable movement.

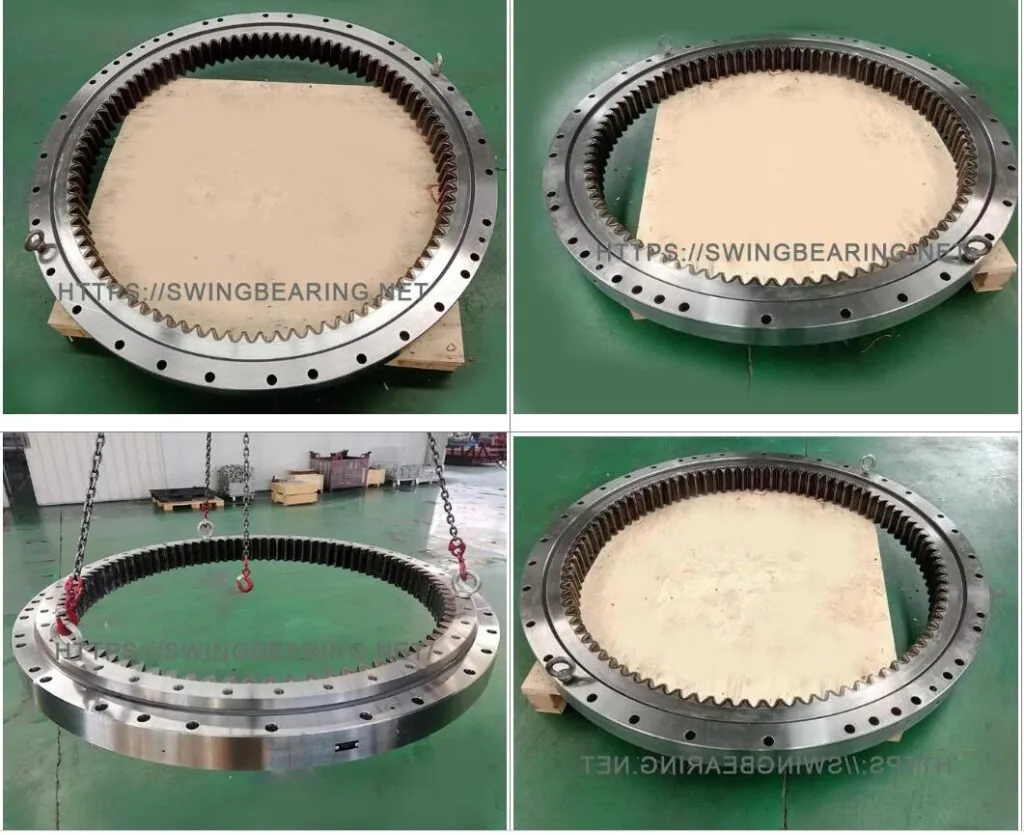

A swing bearing comprises several key components that work together to facilitate rotation:

There are different types of swing bearings, each designed to meet specific operational requirements:

Swing bearings are designed to support both axial and radial loads, as well as tilting moments. This load-bearing capability is crucial for maintaining the stability of the excavator’s upper structure during operation. The rolling elements distribute the loads evenly across the bearing, minimizing wear and ensuring smooth movement.

The inner and outer rings, along with the rolling elements, create a mechanism that allows for rotation. When the hydraulic motor applies torque to the swing gear, the outer ring rotates around the inner ring. The rolling elements facilitate this movement by reducing friction, enabling smooth and efficient rotation.

Seals play a vital role in protecting the swing bearing from contaminants that could compromise its performance. They keep out dirt, water, and debris while retaining the lubricant inside the bearing assembly. Proper lubrication is essential to minimize friction, reduce wear, and prolong the bearing’s lifespan. Regular maintenance ensures that the swing bearing remains well-lubricated and free from contaminants.

Swing bearings provide the precision and control needed for accurate positioning of the excavator’s upper structure. This precision is vital for tasks such as digging, lifting, and placing materials. The ability to rotate the upper structure smoothly and precisely enhances the operator’s efficiency and productivity.

By distributing loads evenly and supporting the upper structure, swing bearings contribute to the overall stability of the excavator. This stability is crucial for maintaining safety during operation, especially when working with heavy loads or in challenging conditions. A well-maintained swing bearing ensures that the excavator operates smoothly and safely.

The 360-degree rotation enabled by the swing bearing provides unmatched versatility and flexibility. It allows the operator to work in confined spaces, navigate obstacles, and reach difficult areas without repositioning the machine. This versatility enhances the excavator’s performance and adaptability to various tasks.

Regular inspections are essential to ensure the swing bearing’s optimal performance. Technicians should check for signs of wear, damage, and contamination. Inspections should include visual checks, lubrication assessments, and measurements of bearing play and backlash.

Proper lubrication is critical for minimizing friction and wear. Technicians should follow the manufacturer’s recommendations for lubrication intervals and types of lubricants. Additionally, seals should be inspected and replaced if damaged to prevent contaminants from entering the bearing assembly.

If wear or damage is detected during inspections, prompt action is necessary to prevent further deterioration. This may involve replacing worn components, re-lubricating the bearing, or adjusting the bearing play. In severe cases, the entire swing bearing assembly may need to be replaced.

Swing bearings are exposed to harsh environmental conditions, including dirt, water, and extreme temperatures. These factors can accelerate wear and compromise performance. Implementing protective measures such as seals and covers, along with regular maintenance, can mitigate the impact of environmental factors.

Excessive loads and stresses can cause premature wear and failure of swing bearings. Proper load management involves ensuring that the excavator operates within its design limits and avoiding overloading. Training operators on best practices and adhering to load capacity guidelines are essential for prolonging bearing life.

The manufacturing process of swing bearings involves precision engineering and strict quality control. High-quality materials, accurate machining, and thorough testing ensure that the bearings can withstand the demands of excavator operation. Investing in high-quality swing bearings from reputable manufacturers is crucial for reliability and longevity.

Innovations in materials science have led to the development of advanced materials for swing bearings. These materials offer improved strength, durability, and resistance to wear and corrosion. Advanced materials enhance the performance and longevity of swing bearings, reducing maintenance requirements and downtime.

Smart bearing technology integrates sensors and monitoring systems into the bearing assembly. These sensors provide real-time data on bearing condition, lubrication levels, temperature, and load. Smart bearings enable predictive maintenance, allowing operators to address issues before they lead to failure, enhancing reliability and reducing downtime.

New lubrication systems and technologies ensure consistent and efficient lubrication of swing bearings. Automated lubrication systems deliver precise amounts of lubricant at regular intervals, reducing the risk of under-lubrication or over-lubrication. Enhanced lubrication systems improve bearing performance and extend their lifespan.

In conclusion, the svänglager plays a crucial role in facilitating the rotation of an excavator’s upper structure. By supporting loads, enabling smooth rotation, and ensuring precise control, swing bearings contribute to the excavator’s efficiency, versatility, and safety. Proper maintenance, regular inspections, and adherence to best practices are essential for prolonging the life and performance of swing bearings. As technology advances, innovations in materials, smart bearings, and lubrication systems continue to enhance the capabilities and reliability of swing bearings, ensuring their vital role in excavator operation.

A1: Swing bearings should be inspected regularly, with the frequency depending on the operating conditions and usage. Generally, monthly inspections are recommended, but high-usage or harsh environments may require more frequent checks.

A2: Signs of a failing swing bearing include abnormal noises during rotation, increased bearing play or backlash, visible wear or damage, and leaks or contamination in the lubrication system.

A3: In some cases, swing bearings can be repaired by replacing worn components or re-lubricating the assembly. However, severe damage or excessive wear may require the entire bearing to be replaced to ensure safe and reliable operation.

A4: The recommended lubrication for swing bearings depends on the manufacturer’s specifications. Generally, high-quality grease or oil with good load-carrying capacity and resistance to water and contaminants is used. Always refer to the manufacturer’s guidelines for specific lubrication recommendations.

A5: Improper installation can lead to misalignment, uneven load distribution, and premature wear of swing bearings. Ensuring proper alignment, following torque specifications, and adhering to installation procedures are crucial for optimal performance and longevity.

A6: Innovations such as advanced materials, smart bearings with integrated sensors, and enhanced lubrication systems are improving the performance and reliability of swing bearings. These technologies provide better durability, real-time monitoring, and efficient lubrication, reducing maintenance requirements and downtime.