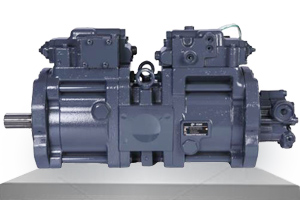

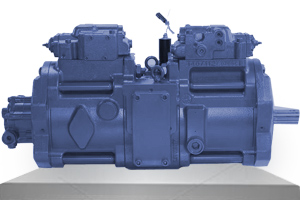

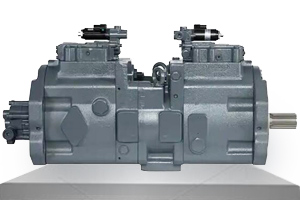

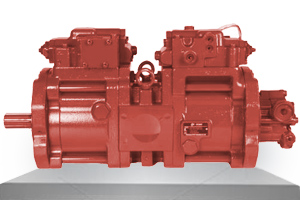

The hydraulic pump integrated into excavators serves as a vital component responsible for converting mechanical energy into hydraulic power, thereby enabling the seamless operation of hydraulic systems to ensure precise control over a myriad of movements. This intricate mechanism, typically driven by the engine, plays a pivotal role in facilitating essential functions such as excavation, material handling, and lifting operations on construction sites. Without the hydraulic pump, the arm of the excavator would remain stationary, underscoring the indispensable nature of this component in enabling the machine to execute tasks efficiently and effectively, ultimately enhancing the operational capabilities of the excavator's hydraulic system for optimal performance.

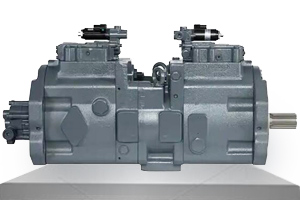

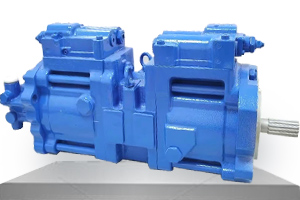

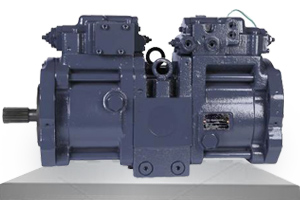

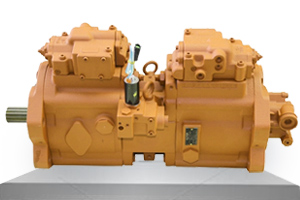

In the domain of excavator hydraulic systems, a diverse range of hydraulic pump variants exists, with gear pumps, vane pumps, and piston pumps standing out as the primary options available. Among these alternatives, piston pumps emerge as the preferred choice for excavators due to their exceptional capacity to adeptly handle high-pressure applications with a remarkable combination of efficiency and durability. The innovative design and robust construction of piston pumps empower them to deliver unparalleled performance across a wide spectrum of viscosities, outperforming their gear and vane pump counterparts in challenging operational environments. This inherent superiority in performance and reliability positions piston pumps as the ideal solution for ensuring optimal functionality and longevity within excavator hydraulic systems, contributing significantly to elevating the machine's overall operational efficiency.

The strategic integration of piston pumps within excavator hydraulic systems underscores the critical importance of selecting high-quality components to enhance performance and productivity in demanding construction environments. Leveraging the advanced capabilities and precision engineering of piston pumps, excavators can achieve enhanced control, responsiveness, and operational efficiency, enabling operators to navigate through rigorous tasks with heightened accuracy and effectiveness. By harnessing the power of piston pumps, excavator operators can unlock a new level of operational excellence, characterized by improved performance metrics and heightened productivity, thereby solidifying the pivotal role of hydraulic pumps in driving the success and efficiency of excavator operations in construction settings.

Xuzhou National Construction Machinery is dedicated to providing your excavators with powerful hydraulic pumps to excel in heavy-duty tasks. Excavator Hydraulic Pumps are the powerhouse behind your machines, providing the essential muscle needed for heavy lifting and rigorous tasks. At the core of this system lies the main pump, the heart of your excavator’s hydraulic function. Any malfunction in its critical components—such as bearings, shafts, heads, coils, pistons, barrel springs, or other vital parts—can bring your entire project to an abrupt halt. These issues can stem from factors like over-pressurization, poor maintenance practices, fluid contamination, or routine wear and tear.

We understand the urgency and importance of maintaining uninterrupted operations. That’s why we are committed to quickly delivering the high-quality Excavator Hydraulic Pumps you need to keep your machines running smoothly. We stock an extensive range of main pumps from all the leading manufacturers in the industry, including CAT, HITACHI, KOMATSU, KOBELCO, HYUNDAI, VOLVO, CASE, and many more. Our inventory is meticulously curated to ensure reliability and performance, giving you peace of mind and the confidence to tackle any job.

Whether you’re facing unexpected downtime or planning a preventative maintenance schedule, we are your trusted partner for premium hydraulic pump solutions. We pride ourselves on our quick shipping capabilities, ensuring that you receive the necessary components without delay. Our team of experts is always ready to assist you in finding the right pump for your specific needs and applications.

We understand that downtime can be costly and disruptive, which is why our commitment to swift and reliable service is unwavering. Our customer support team is dedicated to providing you with timely and effective solutions, ensuring that your operations remain smooth and efficient. Trust us to provide the robust and dependable hydraulic pumps that keep your excavators performing at their best, project after project.

With our extensive industry knowledge and commitment to excellence, you can be confident that you’re getting top-notch products and unparalleled service. Choose us for your hydraulic pump solutions and experience the difference that quality and reliability can make. Our mission is to support your success by delivering exceptional products and service that you can rely on, every time.

Gear pumps, commonly integrated into excavators, consist of interlocking gears typically made from steel or cast iron enclosed within a casing. The operation of gear pumps is centered around the rotational movement of these intermeshing gears, creating a suction effect that draws hydraulic fluid into the system. Known for their simplicity and reliability, gear pumps are often selected for applications requiring lower hydraulic output levels due to their efficient design and ease of maintenance.

Piston pumps are favored in excavators requiring a higher hydraulic output to efficiently power various hydraulic functions. These pumps operate on the principle of reciprocating pistons that generate hydraulic energy by moving back and forth within the pump mechanism. The precision and power offered by piston pumps make them an ideal choice for heavy-duty excavator tasks that demand consistent and reliable performance.

Vane pumps have gained popularity in the excavator industry for their compact size, energy efficiency, and versatility in managing a diverse range of operating speeds. Comprising a rotor with vanes that slide in and out of meticulously machined slots within the pump housing, vane pumps create a vacuum and pressure differential to facilitate fluid movement. Widely utilized in both medium-sized and large excavators, vane pumps offer a reliable and streamlined hydraulic solution for a variety of excavation applications.

Axial piston pumps feature a circular arrangement of pistons around a core shaft, with each piston reciprocating along the axis of the shaft. This reciprocating motion draws hydraulic fluid into the pump and expels it under pressure, effectively converting mechanical energy into hydraulic energy. Axial piston pumps are renowned for their high efficiency and precision, making them an optimal choice for excavators requiring substantial power output and pressure capabilities.

Radial piston pumps operate by pushing pistons outward from the center within radial grooves inside the pump housing, generating pressure to drive hydraulic fluid flow. The radial movement of pistons creates a pumping action that enables these pumps to deliver high pressures consistently, making them well-suited for demanding applications in heavy-duty excavators that require robust hydraulic performance.

By comprehensively examining the characteristics and functionalities of gear pumps, piston pumps, vane pumps, axial piston pumps, and radial piston pumps in excavators, operators can make informed decisions to enhance operational efficiency, productivity, and reliability in diverse excavation tasks. The selection of appropriate hydraulic pump technology is paramount in optimizing excavator performance and ensuring seamless operations on construction sites.

When an excavator hydraulic pump is failing, there are several common signs to look out for. Firstly, a noticeable decrease in hydraulic power is a key indicator. You may observe slower operation of the excavator's hydraulic functions, such as the boom, bucket, or arm movements. This reduced power can affect the overall performance and efficiency of the machine, impacting productivity on the job site.

Another sign of a failing hydraulic pump is unusual noises coming from the pump or hydraulic system. You might hear whining, grinding, or knocking sounds when operating the excavator. These noises indicate internal damage or wear within the pump components, signaling a potential issue that needs attention. Ignoring these sounds can lead to further damage and costly repairs down the line.

Additionally, leaks in the hydraulic system are a clear sign of a failing pump. If you notice hydraulic fluid pooling under the excavator or visible leaks around the pump or hydraulic lines, it is a strong indication of a problem. Leaks not only lead to a loss of hydraulic fluid, but they can also result in decreased performance and potential safety hazards on the job site. It is crucial to address any leaks promptly to prevent further damage to the pump and other hydraulic components.

Lastly, a sudden increase in hydraulic fluid temperature can also signal a failing hydraulic pump. If the hydraulic fluid becomes hotter than usual during operation, it may indicate that the pump is working harder to maintain pressure, leading to overheating. Monitoring the temperature of the hydraulic fluid regularly can help identify potential issues with the pump before they escalate into more significant problems.

The lifespan of a pump in a heavy machinery excavator can vary depending on several key factors. These factors include the quality of the pump, the operating environment of the excavator, maintenance practices, and the frequency and intensity of usage. Proper consideration of these factors is crucial in determining the durability and longevity of the pump within the excavator's systems.

In general, a well-maintained pump in a heavy machinery excavator can last anywhere from 5,000 to 10,000 hours of operation. However, the actual lifespan of a pump may vary based on the specific conditions and demands placed on the excavator. Regular maintenance, timely servicing, and adherence to manufacturer guidelines are essential in maximizing the pump's lifespan and ensuring optimal performance of the excavator.

One of the primary factors influencing the lifespan of a pump is the quality of the pump itself. Pumps constructed from high-quality materials and engineered to withstand the rugged conditions of heavy machinery usage are more likely to have an extended lifespan. Investing in pumps from reputable manufacturers known for producing durable and reliable components can contribute to improved longevity and reduced downtime for the excavator.

Additionally, using pumps that are specifically designed for heavy machinery applications and are correctly sized and rated for the excavator's systems is crucial in ensuring longevity. Properly matched pumps will experience less strain, wear, and tear, resulting in increased durability and efficiency. Selecting pumps that meet the requirements of the excavator's hydraulic and fluid systems is essential for maximizing performance and prolonging the pump's operational lifespan.

By understanding the critical factors that influence the lifespan of pumps in heavy machinery excavators and implementing proactive maintenance practices, operators can enhance the reliability, efficiency, and longevity of their equipment. Prioritizing the selection of high-quality pumps and adhering to recommended maintenance schedules are essential steps in optimizing the performance and durability of pumps within heavy machinery excavators.

Fluid contamination stands out as a primary culprit behind hydraulic pump failure. Contaminants such as dirt, debris, and moisture can compromise the pump's performance and harm its internal components. Regular maintenance practices, including keeping hydraulic fluid clean and conducting routine inspections to replace filters, are crucial in preventing fluid contamination and preserving the pump's integrity.

Cavitation poses a silent threat to hydraulic pumps, occurring when the hydraulic fluid undergoes low pressure, forming vapor bubbles that collapse rapidly. These collapsing bubbles generate shockwaves that can erode pump surfaces and disrupt their functionality. To mitigate cavitation, ensuring proper fluid levels, unrestricted flow, and maintaining correct pressure levels are essential practices in safeguarding the pump's longevity.

Operating hydraulic pumps at elevated temperatures can expedite wear and lead to premature failure of critical components. High temperatures can trigger fluid degradation, seal malfunctions, and diminished pump efficiency. Monitoring and controlling the operating temperature of the hydraulic system, possibly implementing cooling measures, are vital strategies in preventing excessive heat-induced damage and preserving the pump's performance.

Uncorrected leaks in hydraulic connections or damaged seals can introduce air into the system, compromising pump performance and escalating the risk of failure over time. Addressing and rectifying leaks promptly is essential in maintaining optimal system functionality, preventing air ingress, and sustaining the pump's operational efficiency in the long run.

By understanding and addressing the common causes of hydraulic pump failure, operators can proactively safeguard the integrity and performance of their hydraulic systems. Implementing preventive maintenance measures, monitoring system parameters, and promptly addressing issues can help mitigate the risks of pump failure, prolong the pump's lifespan, and ensure the reliable operation of heavy machinery and equipment.

Improving the efficiency of your excavator's hydraulic pump system is essential for maximizing productivity and reducing operating costs. There are several steps you can take to enhance the performance of the hydraulic system. Firstly, regular maintenance is key to ensuring optimal efficiency. This includes routine inspections of the hydraulic components, such as the pump, valves, and cylinders, to check for any signs of wear or damage. Keeping the hydraulic system clean and properly lubricated can also help reduce friction and improve overall efficiency.

Secondly, consider upgrading to high-quality hydraulic fluids that are specifically designed for your excavator's hydraulic system. Using the right type of hydraulic fluid can help maintain proper viscosity, reduce wear on components, and improve overall system performance. Additionally, ensuring the hydraulic fluid is at the correct level and free of contaminants will help prevent issues that can reduce the efficiency of the hydraulic pump system.

Another way to improve the efficiency of your excavator's hydraulic pump system is to optimize the system settings and operating practices. This includes adjusting the hydraulic pressure and flow settings to match the requirements of the job at hand. Avoiding excessive pressure and flow rates can help minimize energy consumption and reduce wear on the hydraulic components. Furthermore, operating the excavator smoothly and avoiding abrupt movements can help prolong the life of the hydraulic pump and improve overall system efficiency.

Lastly, consider implementing telematics or monitoring systems to track the performance of the hydraulic pump system. These systems can provide valuable data on the usage and condition of the hydraulic components, allowing you to identify areas for improvement and optimize the system for maximum efficiency. By taking proactive steps to maintain and optimize your excavator's hydraulic pump system, you can enhance performance, extend the lifespan of the components, and ultimately increase the efficiency of your machine.

Proper maintenance of an excavator hydraulic pump is crucial to ensure its longevity and optimal performance. To maintain an excavator hydraulic pump effectively, regular inspections are essential. Inspect the pump for any signs of leaks, unusual noises, or decreased performance, as these can indicate potential issues that need to be addressed promptly. Additionally, check the hydraulic fluid level and quality regularly to ensure it is clean, at the correct level, and free of contaminants that could damage the pump.

Regularly changing the hydraulic fluid and filters is another important aspect of maintaining an excavator hydraulic pump. Over time, hydraulic fluid can degrade and become contaminated, leading to decreased pump efficiency and potential damage to the system. By following the manufacturer's recommendations for fluid and filter changes, you can help prevent premature wear on the pump and other hydraulic components, ensuring smooth operation and extended lifespan.

Furthermore, it is crucial to keep the hydraulic system clean and free of debris that could clog or damage the pump. Regularly inspect and clean the hydraulic lines, fittings, and other components to prevent the accumulation of dirt and debris that can affect the pump's performance. Additionally, ensure that all hydraulic connections are tight and secure to prevent leaks that could lead to pump damage and decreased efficiency.

Lastly, proper storage and operating practices can also contribute to the maintenance of an excavator hydraulic pump. Store the excavator in a clean, dry environment to prevent moisture and contaminants from affecting the hydraulic system. During operation, avoid overloading the hydraulic system and use the excavator controls smoothly and precisely to minimize wear on the pump. By following these maintenance practices consistently, you can help prolong the life of your excavator hydraulic pump and ensure reliable performance on the job site.

Replacing an excavator hydraulic pump is a complex task that requires careful planning and attention to detail. The process involves several steps to ensure the successful installation of the new pump. Firstly, it is crucial to disconnect the excavator from any power source and relieve the hydraulic system pressure to prevent any accidents during the replacement. This can be done by operating the hydraulic controls to release any built-up pressure in the system.

Next, the old hydraulic pump needs to be located and removed from the excavator. This typically involves disconnecting the hydraulic lines, electrical connections, and mounting bolts securing the pump to the machine. It is essential to follow the manufacturer's guidelines and reference the excavator's service manual to ensure proper disassembly and removal of the pump without causing damage to other components.

After removing the old pump, the new hydraulic pump can be installed following the reverse procedure. Carefully align the new pump with the mounting position, reattach the hydraulic lines and electrical connections, and secure the pump in place with the mounting bolts. It is essential to double-check all connections and ensure they are tightened to the manufacturer's specifications to prevent leaks and ensure proper functionality of the new pump.

Once the new hydraulic pump is installed, the hydraulic system pressure can be restored, and the excavator can be tested to ensure the pump is operating correctly. It is recommended to perform a thorough inspection of the hydraulic system for any leaks or abnormal noises and to test the excavator's hydraulic functions to confirm that the new pump is functioning as expected. Regular maintenance and monitoring of the hydraulic system can help prevent future issues and prolong the life of the excavator hydraulic pump.

Časť #: VOE 14522561 14250327 14250328 14244106 14245961

Urobte:Volvo

Model: EC700B EC620 EC650

Stav: Nový

Časť #: VOE 14214127 VOE 14344193 VOE 14215385 VOE 14343112

Urobte:Volvo

Model: EW200 EC200

Stav: Nový

Časť #: SA 1142-06230 14526609 14618624 14612484

Urobte:Volvo

Model: EC460

Stav: Nový

Časť #: SA 7220-00601

Urobte:Volvo

Model: EC290 EC210

Stav: Nový

Časť #: VOE14522561 VOE14621492

Urobte:Volvo

Model: EC700

Stav: Nový

Časť #: 705-41-08080

Urobte:Komatsu

Model: PC25-1 PC38UU-2

Stav: Nový

Časť #: 705-41-08080

Urobte:Komatsu

Model: PC25-1 PC38UU-2

Stav: Nový

Časť #: 708-23-04014 708-23-04013 708-23-04012

Urobte:Komatsu

Model: PC100-5 PC120-5 PC130-5

Stav: Nový