Slew ring bearings are vital components in heavy machinery, designed to support large axial, radial, and overturning loads simultaneously. With unique structural features, these bearings offer efficient load management, making them integral to various industrial applications. In this article, we will delve into the critical aspects of slew ring bearing design, explore its different structural types, and examine the specific load conditions each type can handle effectively.

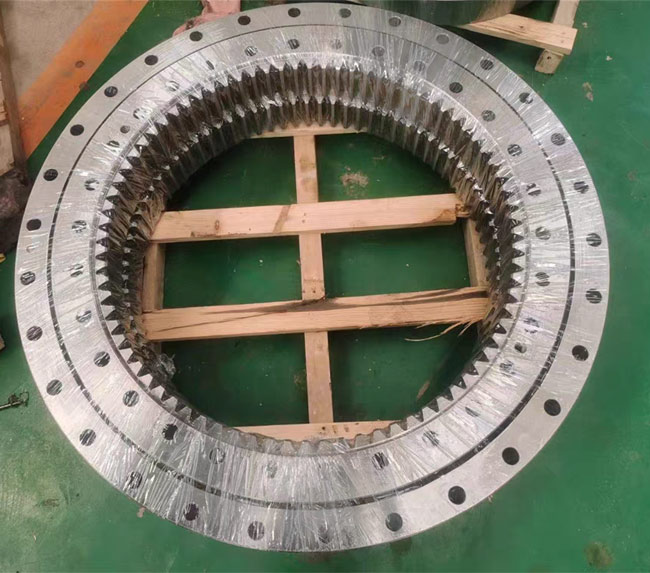

Slew ring bearings, commonly used in construction, mining, and metallurgical machinery, are engineered for high durability and versatility. Unlike standard rolling bearings, slew ring bearings come equipped with mounting holes, lubricating ports, and sealing devices. These features allow for customized application across different machinery types, providing a compact, maintenance-friendly solution for medium and large rotary devices.

Slew ring bearings are classified based on their structural form and gear configuration. Here, we outline the major types and their respective design features:

| Type of Slew Ring Bearing | Design Features | Common Applications |

|---|---|---|

| Four-Point Contact Ball Bearing | Single row of balls, high dynamic load capacity | Excavators, cranes, and rotary platforms |

| Double-Row Ball Bearing | Two rows of balls, improved load distribution | Tower cranes, wind turbines, and hoisting devices |

| Cross Roller Slew Bearing | Alternating rollers, high static load capacity | Heavy-duty turntables, robotics, and precision machinery |

| Three-Row Roller Bearing | Three separate roller groups, maximized load capacity | Ship cranes, port machinery, and offshore equipment |

The four-point contact ball bearing features a single row of balls that make contact at four points within the raceway. This design allows it to handle significant dynamic loads, making it ideal for applications that require smooth and precise movement, such as excavators and cranes.

Vantagens:

A double-row ball bearing design includes two rows of ball elements, which enhances its load-carrying capabilities, particularly under combined axial and radial loads. This configuration is commonly used in wind turbines and tower cranes, where stability is crucial.

Vantagens:

The cross roller bearing consists of cylindrical rollers arranged perpendicularly, offering high rigidity and excellent static load capacity. This design is suitable for heavy-duty applications, such as robotic arms and high-precision machinery.

Vantagens:

The three-row roller design features three separate roller groups, each handling a different type of load (axial, radial, or overturning). This structure enhances the bearing’s overall load capacity and reduces the diameter needed for a given load, making it a preferred choice for large, heavy-duty equipment like ship cranes and port handling machinery.

Vantagens:

The choice of slew ring bearing depends largely on the specific load conditions of the application. Different structural designs cater to various load scenarios:

| Bearing Type | Dynamic Load Capacity | Static Load Capacity | Application Examples |

|---|---|---|---|

| Four-Point Contact Ball | High | Moderate | Excavators, Cranes |

| Double-Row Ball | Moderate | Moderate | Wind Turbines, Hoisting Devices |

| Cross Roller | Moderate | High | Robotics, Precision Turntables |

| Three-Row Roller | High | High | Ship Cranes, Port Machinery |

What factors should be considered when selecting a slew ring bearing?

A: Key considerations include load capacity, rotation speed, precision requirements, and environmental conditions. It’s essential to choose a bearing type that matches the specific demands of the application.

How often should slew ring bearings be lubricated?

A: Lubrication intervals depend on operating conditions and load requirements. Generally, it is recommended to lubricate every 100 to 500 operational hours, but refer to the manufacturer’s guidelines for precise intervals.

Can a single slew ring bearing type be used for all applications?

A: No, different applications have unique load requirements and environmental conditions. Choosing the correct bearing type is crucial for optimal performance and longevity.

What are the common signs of wear or failure in slew ring bearings?

A: Indications of wear include increased vibration, noise, and visible play or misalignment in the bearing assembly. Regular inspection and maintenance can help detect early signs of failure.

How can I extend the lifespan of my slew ring bearing?

A: Proper installation, regular lubrication, and timely inspection are key practices for extending bearing lifespan. Avoiding excessive loads and ensuring correct alignment during installation can also prevent premature wear.

Slew ring bearings play a critical role in the functionality and stability of heavy machinery. Understanding the different types of bearing designs and their specific applications allows for better selection and maintenance strategies, ultimately enhancing performance and reducing downtime. By implementing proper installation techniques and adhering to maintenance schedules, operators can ensure the long-term reliability and efficiency of their equipment.