The manufacturing process and detailed steps of rolamento de balanço da escavadora begin with the cutting of slewing bearing steel raw materials. High-quality steel, specifically chosen for its strength and durability, is used to produce swing bearings. The raw material is inspected to ensure it meets the required specifications, which include the right chemical composition and physical properties. Cutting involves using advanced machinery to precisely cut the steel into appropriate sizes, forming the basic shape of the slewing bearing. This step is crucial as it determines the initial dimensions and quality of the final product.

Next in the manufacturing process is the forging of the swing bearing billet. Forging involves heating the steel billets to a high temperature until they become malleable. These heated billets are then shaped into the desired form using powerful hydraulic presses or forging hammers. This process not only shapes the steel but also enhances its mechanical properties, such as strength and toughness. The forging of the swing bearing billet is essential to create a robust structure capable of withstanding the significant loads and stresses that the bearing will encounter during operation.

Following billet forging, the next step in the manufacturing process and detailed steps of excavator swing bearing is the forging ring of the swing bearing. In this phase, the roughly forged billets are further processed to create a seamless ring. This involves rolling the billets into rings of specific dimensions and then welding or joining them to form a continuous loop. The forging ring process ensures that the swing bearing has a uniform shape and thickness, which is critical for its balance and performance. This step also involves stringent quality checks to identify and rectify any defects.

Rough turning is a critical stage in the manufacturing process and detailed steps of rolamento de balanço da escavadora. During this process, the forged rings undergo rough machining to bring them closer to their final dimensions. Lathes and other machining tools are used to remove excess material and shape the bearing into a more defined form. Rough turning sets the stage for finer machining processes by establishing the basic geometry and alignment of the swing bearing. This step ensures that the bearing has the correct proportions and that any irregularities are addressed before proceeding to more precise operations.

Heat treatment, or quenching, is performed to enhance the durability and hardness of the swing bearing. This process involves heating the bearing to a specific temperature and then rapidly cooling it in water or oil. Quenching transforms the steel’s microstructure, significantly increasing its hardness and wear resistance. This step is crucial for the longevity and reliability of the swing bearing, as it prepares the material to withstand the heavy loads and harsh conditions it will encounter in an excavator. The heat treatment process is carefully controlled to ensure the desired mechanical properties are achieved.

Opening processing is the next step in the manufacturing process and detailed steps of excavator swing bearing. This involves drilling holes and creating slots in the bearing to accommodate various components such as bolts, gears, and lubrication ports. Precision drilling machines are used to ensure that these openings are accurately positioned and sized. This step is vital for the proper assembly and functionality of the swing bearing, as these openings facilitate the integration of the bearing into the excavator’s structure. The accuracy of this process directly impacts the performance and reliability of the final product.

Fine grinding is a meticulous process that further refines the dimensions and surface finish of the swing bearing. Using precision grinding machines, the bearing’s surfaces are smoothed to meet strict tolerance requirements. This step is essential for ensuring the bearing’s rotation is smooth and frictionless, which is critical for the efficient operation of the excavator. Fine grinding also removes any remaining surface imperfections, enhancing the bearing’s overall quality and performance. The precision achieved during fine grinding contributes to the longevity and reliability of the rolamento oscilante.

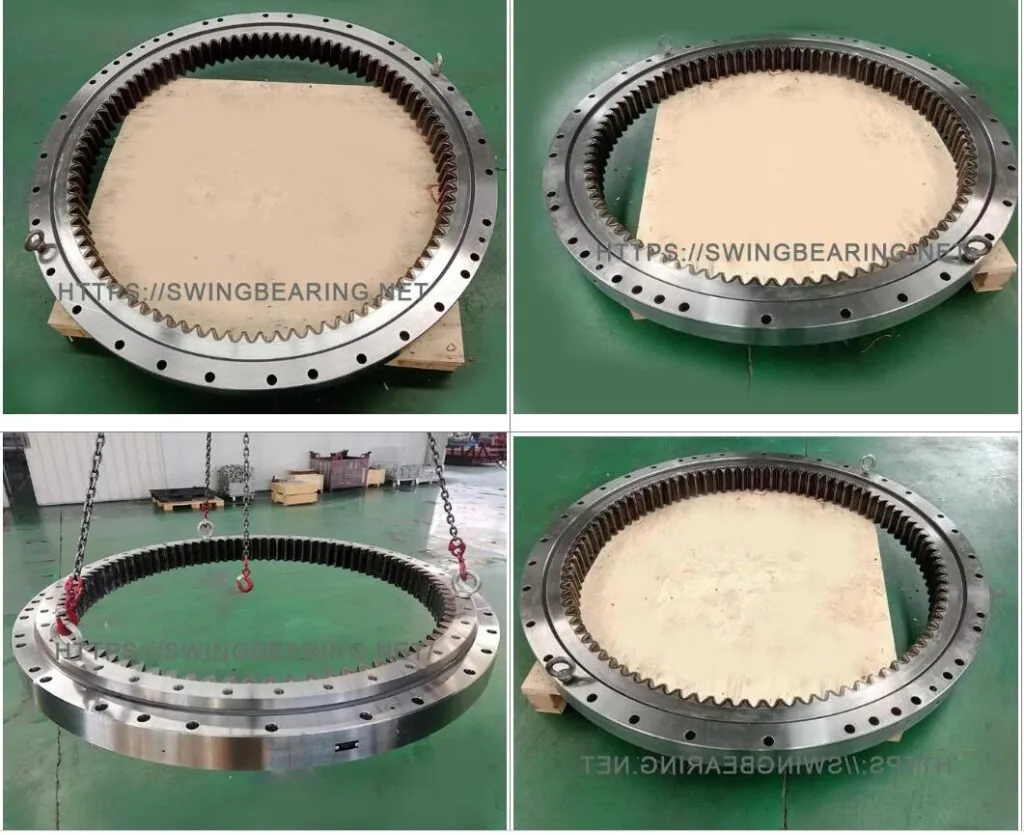

The assembly operations are a critical phase in the manufacturing process and detailed steps of excavator swing bearing. During this stage, all the components of the swing bearing are meticulously assembled. This includes fitting the rolling elements, such as ball bearings or rollers, into the raceways. Each component is carefully placed to ensure optimal performance. The assembly process also involves thorough inspection and testing to verify that the bearing operates smoothly and meets all specified criteria. Proper assembly is vital for the bearing’s functionality and its ability to withstand the operational demands of an excavator.

The final step in the manufacturing process is the packaging of the finished swing bearing. After the bearing passes all quality inspections and tests, it is carefully cleaned and coated with a protective layer to prevent corrosion during storage and transportation. The bearing is then securely packed in specially designed packaging materials that protect it from damage. Proper packaging is essential to ensure that the swing bearing reaches its destination in perfect condition, ready for installation and use in an excavator. This step completes the manufacturing process, delivering a high-quality product to customers.

1. What materials are used for manufacturing excavator swing bearings?

The primary material used for manufacturing excavator swing bearings is high-quality steel. This steel is chosen for its strength, durability, and ability to withstand the heavy loads and stresses encountered in excavator operations. Additionally, the steel undergoes various treatments and processes to enhance its mechanical properties and ensure the bearing’s longevity.

2. Why is heat treatment essential in the manufacturing process of swing bearings?

Heat treatment, or quenching, is crucial because it significantly enhances the hardness and wear resistance of the swing bearing. By heating the bearing to a specific temperature and then rapidly cooling it, the steel’s microstructure is transformed, resulting in improved durability. This process prepares the bearing to endure the heavy loads and harsh conditions it will face in an excavator.

3. What is the role of fine grinding in the manufacturing process of swing bearings?

Fine grinding is a precision process that refines the dimensions and surface finish of the swing bearing. It ensures that the bearing’s surfaces are smooth and meet strict tolerance requirements, which is vital for smooth and frictionless rotation. This step also removes any remaining surface imperfections, contributing to the overall quality and performance of the swing bearing.

4. How are swing bearings protected during storage and transportation?

Swing bearings are protected during storage and transportation by applying a protective layer to prevent corrosion. Additionally, they are securely packed in specially designed packaging materials that shield them from damage. This ensures that the bearings reach their destination in perfect condition, ready for installation and use.

5. What quality checks are performed during the manufacturing process of swing bearings?

Quality checks are performed at various stages of the manufacturing process, including the inspection of raw materials, monitoring of forging and machining processes, heat treatment verification, and final assembly testing. These checks ensure that the swing bearings meet all specified criteria and operate smoothly. Any defects or irregularities are identified and rectified to maintain the bearing’s high quality.

The manufacturing process and detailed steps of excavator swing bearing involve a series of meticulous and highly controlled procedures. From cutting the steel raw materials to the final packaging, each step is designed to ensure the highest quality and performance of the swing bearing. The detailed process includes cutting, forging, machining, heat treatment, and assembly, each contributing to the bearing’s durability and reliability. Understanding these steps provides insight into the complexity and precision required to produce such a critical component. Proper maintenance and timely replacement of swing bearings are crucial for the efficient operation of excavators, ensuring they perform optimally in demanding conditions. The detailed and rigorous manufacturing process ensures that each swing bearing meets the stringent standards required for heavy-duty applications, ultimately contributing to the overall efficiency and longevity of excavators.