Rotary bearings are critical components in various mechanical systems, requiring meticulous attention during transportation, installation, and maintenance. This blog provides an in-depth look at best practices to ensure the longevity and optimal performance of your rotary bearings. We’ll cover essential steps for handling, storing, installing, and maintaining slewing bearings.

Slewing bearings are vital in applications requiring rotation and load-bearing capabilities, such as cranes, excavators, and wind turbines. Proper transportation, installation, and maintenance are crucial to prevent damage and ensure their efficiency and durability. This guide outlines the best practices for handling these components, ensuring you can maximize their performance and lifespan.

Slewing bearings must be handled with utmost care during loading and unloading to prevent damage. It is advisable to transport and store them horizontally to avoid unnecessary strain on the components. When lifting, use lifting eyebolts in a horizontal manner to prevent collisions, particularly in the radial direction, which could cause significant damage.

Store slewing bearings in a dry indoor environment to prevent rust and corrosion. The surface of the slewing ring turntable is typically coated with an anti-rust agent, offering protection for up to six months. For storage periods exceeding six months, especially for spare parts, reapply rust-proof packaging or implement additional storage measures to maintain their condition.

When removing the packaging, do so with caution to avoid damaging the dust seal. It is best to cut the packaging on the outer diameter rather than the end faces. This careful approach ensures that the integrity of the seal is maintained, protecting the bearing from contaminants.

Before installation, clean the mounting surface of the slewing bearing and the installation base thoroughly using an industrial solvent to remove any oil stains, burrs, paint, or other foreign objects. Avoid using fluorine-containing solvents as they can damage the bearing. Ensure the solvent does not flow into the sealing ring or raceway to prevent contamination.

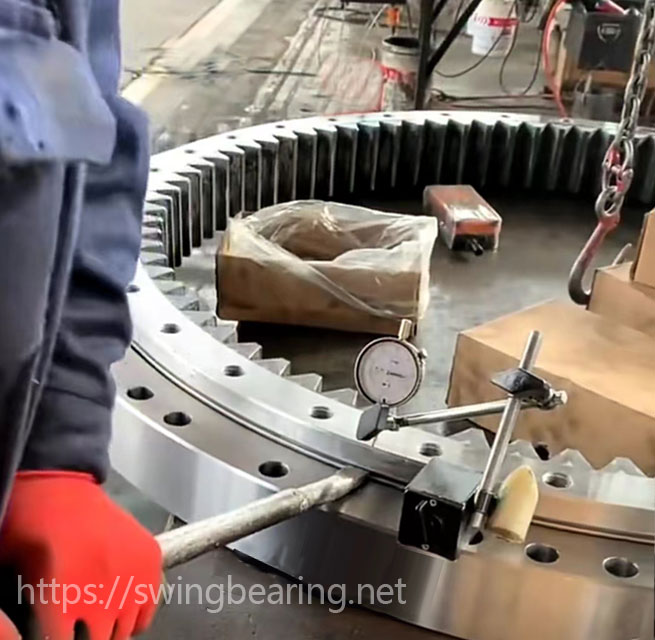

Place the quenching soft zone of the raceway, marked with an “S” on the outside or at the blocking hole, in a non-load area. After positioning the support, check the flatness of the mating surfaces using a feeler gauge. If gaps are detected, re-machine the surfaces. If re-machining is not possible, consider filling or local shimming to prevent raceway deformation after tightening the bolts.

Before tightening the bolts, adjust the tooth side clearance according to the highest point of gear radial runout, indicated by three teeth marked with green. For systems with multiple small gears, ensure each gear is adjusted to the same state to achieve optimal meshing and alignment with the gear ring. After bolt tightening, recheck the tooth side clearance to confirm proper installation.

Tighten the bolts continuously in a 180° symmetrical direction to ensure uniform preloading force across the entire circumference. This method prevents uneven stress distribution, which could affect the performance of the slewing bearing.

Choose connecting bolts that meet the specifications outlined in GB/T5782-2000 and GB/T5783-2000. The bolts should have a strength grade of at least 8.8 as per GB/T3098.1-2000, with 10.9 grade high-strength bolts recommended. For special applications, consider using 8.8 grade or 12.9 grade high-strength bolts.

Avoid using spring washers during installation. Instead, use flat washers that comply with GB/T97.1-1985 and GB/T97.2-1985, and ensure they undergo quenching treatment. The clamping length of the bolts must be at least five times the nominal diameter of the bolt (≥5d) to secure the connection adequately.

When tightening the bolts, ensure a certain preloading force, typically 0.7 times the yield limit of the bolt. This preloading force is crucial to maintain the integrity and stability of the installation, preventing loosening and potential failures.

When rotary bearings are shipped from the manufacturer, they contain a small amount of No. 2 lithium-based grease. However, users must inject new grease according to the specific operating environment to ensure optimal performance.

Different environments and operating conditions require varying lubrication practices:

Maintaining the lubrication of rotary bearings is essential for their smooth operation. The bearings should be rotated evenly during grease injection to ensure uniform distribution. This practice helps in preventing uneven wear and extending the bearing’s lifespan.

The tooth surfaces of the slewing bearing must be kept clean at all times. Regularly clean any oil stains from the tooth surfaces and apply a fresh coat of grease. This maintenance step is crucial to prevent wear and tear and to ensure the proper engagement of the gear teeth.

After the first 100 hours of operation, it is essential to check the preloading force of the bolts. This check should ensure that the bolts are not loose and that they maintain the necessary preloading force. Subsequent checks should be performed every 500 hours of operation to prevent bolt failure and maintain the structural integrity of the bearing.

Regularly monitor the condition of the rotary bearing during operation. Look out for any abnormal noises, impacts, or sudden increases in power consumption. These signs could indicate potential issues that need immediate attention.

If any abnormalities are detected, stop the machine immediately for inspection and troubleshooting. If necessary, perform a thorough disassembly and inspection to identify and rectify the issue. This proactive approach can prevent major failures and costly downtime.

Do not flush the bearing with water during use, as water can infiltrate the raceway and cause damage. Additionally, keep hard objects away from the gear engagement area to prevent damage to the gear teeth.

Frequent checks of the bearing seal are crucial to maintain the integrity of the rotary bearing. If the sealing strip is found to be damaged, replace it promptly to prevent foreign objects from entering the raceway and causing contamination or damage.

Proper transportation, installation, and maintenance of slewing bearings are essential to their performance and longevity. By following these detailed guidelines, you can ensure that your rotary bearings operate efficiently and reliably, minimizing downtime and extending their service life.

A: Slewing bearings should be stored in a dry indoor environment. The surface is typically coated with an anti-rust agent, providing protection for up to six months. For longer storage periods, reapply rust-proof packaging or take additional measures to prevent corrosion.

A: Checking the flatness of mating surfaces ensures that the slewing bearing is properly aligned, preventing deformation of the raceway after tightening the bolts. This step is crucial to maintaining the bearing’s performance and preventing premature wear.

A: Fluorine-containing solvents can damage the sealing ring and raceway of the slewing bearing, leading to contamination and reduced performance. Using appropriate industrial solvents ensures that the bearing remains clean without causing harm.

A: The recommended preloading force for tightening bolts is generally 0.7 times the yield limit of the bolt. This preloading force helps maintain the stability and integrity of the installation, preventing loosening and ensuring reliable operation.

By adhering to these comprehensive guidelines, you can ensure that your slewing bearings are handled, installed, and maintained correctly, maximizing their efficiency and lifespan.