Understanding the operation of an excavator slewing bearing CAT 350 1026392 is crucial for appreciating its role in heavy machinery. Slewing bearings are essential components that support axial loads, radial loads, and tilting moments. Developed in the late 1940s, these bearings have evolved to offer robust and reliable performance in various applications. This blog will delve into the detailed workings of an excavator slewing bearing, including its components, types, and operational principles.

Slewing bearings are pivotal in the functioning of excavators, providing the necessary support and movement capabilities for heavy-duty tasks. These bearings are integral to the operation of the excavator’s turntable, enabling it to rotate and handle substantial loads efficiently. This blog aims to explain the detailed workings of an excavator slewing bearing, highlighting its components, types, and the principle behind its operation.

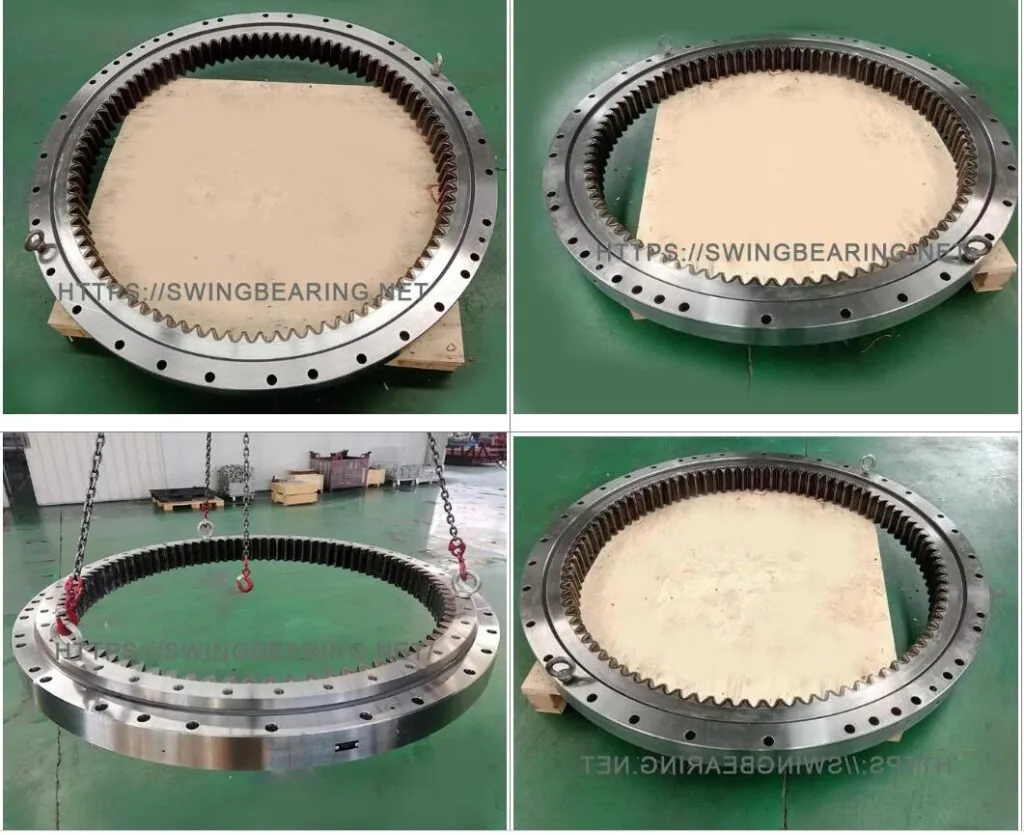

Slewing bearings are sophisticated components designed to handle complex load combinations. They typically consist of the following parts:

This design results in a compact structure that is easy to operate and maintain.

Slewing bearings come in various configurations to suit different operational needs:

Among these, the single row cross roller slewing bearing is notable for its early development, and the single row four-point contact ball type became popular in the 1980s due to its versatility.

The material of slewing bearings varies depending on the application:

The slewing bearing in an excavator comprises:

The excavator’s vertical load, horizontal load, and overturning moment are transferred from the turntable through the outer race, rolling elements (balls or columns), and inner race to the chassis. The rolling elements reduce friction and support the loads efficiently.

The housing of the rotary mechanism is fixed to the turntable, and it meshes with the gear ring on the inner race via a pinion. The pinion can rotate around its own axis and revolve around the turntable’s centerline. When the rotary mechanism is activated, the turntable rotates relative to the chassis, enabling the excavator to maneuver.

Proper maintenance is essential to prolong the life of the slewing bearing. Regular lubrication and inspection help prevent wear and tear. Adjusting the clearance during the first installation and periodically thereafter is crucial to ensure optimal performance. Refer to technical guidelines for specific clearance adjustments.

Understanding the detailed operation of Excavator Slewing Bearing CAT 350 1026392 is key to maintaining the efficiency and longevity of these crucial components. From the careful selection of materials to the precise assembly and regular maintenance, each aspect plays a significant role in ensuring the smooth and reliable operation of excavators. By following proper maintenance practices, the lifespan of slewing bearings can be significantly extended, ensuring sustained performance in demanding conditions.

Regular maintenance of the Excavator Slewing Bearing CAT 350 1026392 is crucial for several reasons. First and foremost, proper maintenance helps ensure the smooth operation of the excavator by preventing unexpected breakdowns and costly repairs. By lubricating the bearing regularly, you can reduce friction, wear, and heat generation, thereby extending its lifespan.

Additionally, routine maintenance allows you to detect any early signs of wear or damage, enabling you to address issues promptly before they escalate into more significant problems. This proactive approach not only saves time and money but also improves the safety of the equipment and the operator.

A: Slewing bearings come in various types, such as single row ball, double row ball, single row cross roller, three row roller, and ball and roller combination series. Each type is designed to handle specific load conditions and operational requirements.

The material of the Excavator Slewing Bearing CAT 350 1026392 plays a crucial role in its performance. Typically, these bearings are made of high-quality steel or alloy materials to ensure durability, strength, and resistance to wear and tear. The right material can enhance the bearing’s load-carrying capacity, corrosion resistance, and overall lifespan. So, choosing the appropriate material for the slewing bearing is essential for ensuring optimal performance and longevity of the excavator.

A: The pinion meshes with the gear ring on the inner race of the slewing bearing, enabling the turntable to rotate relative to the chassis. It allows for precise and controlled rotation, crucial for the excavator’s maneuverability.

By understanding and applying these principles, operators can ensure the efficient and reliable functioning of excavator slewing bearings, enhancing the overall performance and durability of the machinery.