Slewing rings, also known as slewing bearings or “machine joints,” play a crucial role in many industries, from construction and mining to military and wind power. These bearings are essential for facilitating rotational movements in heavy machinery such as cranes, excavators, and radar systems. This article delves into the various structural types of slewing rings, their unique characteristics, and their wide range of applications.

Single row four-point contact ball bearings are designed for high static load capacity. They can handle axial loads in both directions as well as radial loads, making them versatile for various applications. The design includes a single row of balls that make contact at four points on the raceway, allowing for the distribution of loads over a wider area.

Three row roller bearings are the most robust type of slewing ring bearings, designed to handle exceptionally heavy loads in multiple directions. This advanced design features three distinct rows of rollers that evenly distribute the load across the bearing, resulting in the highest load capacity among all types of slewing rings. The three rows of rollers are meticulously aligned to manage axial loads, radial loads, and tilting moments simultaneously, making them ideal for applications where extreme strength and durability are paramount. Due to their superior load-bearing capabilities and firm structural integrity, these bearings are especially suitable for heavy-duty applications such as ship cranes, mining equipment, and large-scale construction machinery. The robust construction ensures minimal deformation under heavy loads, thereby enhancing the operational lifespan and reliability of the machinery they are installed in. Additionally, their ability to withstand harsh working environments without compromising performance makes them a preferred choice in industries that demand high resilience and longevity from their equipment.

Single row cross roller bearings are distinguished by their unique design, where cylindrical rollers are arranged crosswise at right angles to one another. This innovative configuration allows the bearing to simultaneously handle axial forces, radial forces, and tilting moments, providing a high level of rigidity and compactness. The cross-roller arrangement ensures that loads are evenly distributed, enhancing the bearing’s capacity to withstand heavy and complex loads. These bearings are widely utilized in hoisting equipment, engineering machinery, and military applications due to their exceptional ability to maintain stability and performance under varying load conditions. The high rigidity and minimal rotational resistance make them ideal for precision applications where accurate movement and positioning are critical. Furthermore, their compact design allows for efficient use of space, which is particularly beneficial in applications with limited installation areas. This combination of high load-bearing capacity, rigidity, and compactness makes single row cross roller bearings a versatile and reliable choice for a wide range of demanding applications.

Double row reducer ball bearings are characterized by their larger axial and radial dimensions, which contribute to their enhanced load-bearing capacity. Featuring two rows of balls, these bearings provide a balanced distribution of loads, significantly improving their ability to handle higher axial and radial forces compared to single-row designs. The dual-row configuration also offers increased stability and support, making them particularly suitable for applications that require handling substantial loads over large diameters. These bearings are ideal for use in tower cranes, truck cranes, and other heavy machinery where large diameters and high load handling are essential. The increased axial and radial dimensions not only enhance load capacity but also contribute to the overall structural integrity of the bearing, ensuring reliable performance under demanding conditions. The robust construction of double row reducer ball bearings helps reduce wear and tear, extending the service life of the machinery they support. Their ability to maintain performance under heavy loads makes them an indispensable component in various industrial applications, ensuring efficient and reliable operation of the equipment.

Slewing rings are notable for their large size, with diameters typically ranging from 0.4 to 10 meters, and in some cases, up to 40 meters. This large size allows them to support substantial structures and machinery.

Unlike standard bearings, slewing rings can bear heavy loads in several directions. They can handle axial and radial forces, as well as large overturning moments, often replacing the need for multiple sets of ordinary rolling bearings in complex applications.

Slewing rings operate at low speeds, usually below 10 rpm. In many applications, they do not run continuously but rotate back and forth within a limited angle, functioning as “swing bearings.” This low-speed operation reduces wear and extends their operational lifespan.

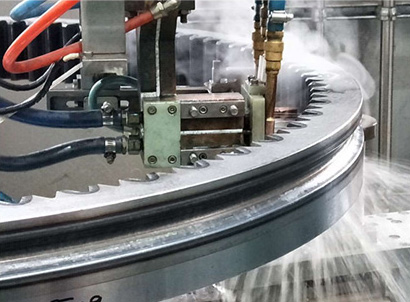

The manufacturing of slewing rings involves specific materials and heat treatments different from those used for standard rolling bearings. These processes enhance the bearing’s durability and performance under heavy loads and harsh conditions.

Slewing rings often come equipped with an integrated ring gear for rotary drive and a sealing device for dustproofing. These features protect the bearing from environmental contaminants and ensure smooth operation.

Slewing rings are installed differently than standard bearings. Instead of being mounted on a mandrel and housed in a bearing housing, slewing rings are screwed to upper and lower support structures, providing a secure and stable mounting.

Slewing rings are indispensable in various industries due to their versatility and load-bearing capabilities. They are used in:

Understanding the structural characteristics and types of slewing rings is essential for selecting the right bearing for specific applications. Whether it’s for handling heavy loads in construction machinery or facilitating precise movements in military equipment, slewing rings offer unparalleled performance and reliability. Proper selection, installation, and maintenance of these bearings can significantly enhance the efficiency and lifespan of the machinery they support.

Slewing rings should be inspected and maintained regularly to ensure optimal performance. It is recommended to conduct inspections every 200-500 operating hours, depending on the operating conditions. Maintenance activities include checking for wear, ensuring proper lubrication, and tightening bolts to the specified torque.

Signs of a failing slewing ring include unusual noises during operation, increased vibration, difficulty in rotation, and visible wear or damage to the bearing components. Additionally, any leakage of lubricants or presence of contaminants in the lubricant can indicate potential bearing failure.

Replacing slewing rings can be a complex task requiring specialized tools and knowledge. While it is possible to replace the bearings yourself, it is generally recommended to hire a professional with experience in handling such components. Professional installation ensures proper alignment, lubrication, and torque settings, reducing the risk of premature failure and ensuring optimal performance.

It is essential to use the lubricant recommended by the bearing manufacturer. The recommended lubricant is specifically formulated to meet the operating conditions and material compatibility of the bearing. Using the correct lubricant helps reduce friction, prevent wear, and extend the bearing’s lifespan. Always refer to the manufacturer’s guidelines or consult with a professional to determine the best lubricant for your specific bearing type.

To extend the life of slewing rings, follow a regular maintenance schedule, including frequent inspections and lubrication. Ensure that the bearings are correctly installed and aligned, and avoid overloading the equipment. Protect the bearings from contaminants and environmental factors, and promptly address any signs of wear or damage. By adhering to these practices, you can significantly extend the lifespan of your slewing rings and maintain optimal equipment performance.