Swing bearings for excavators are one of the most critical components of an excavator, responsible for ensuring the stability and smooth operation of the machine. These bearings enable the excavator to rotate in a 360-degree radius, making them essential for material movement and excavation operations. In this article, we will provide an overview of swing bearings for excavators, their key components, and their functions.

Swing bearings for excavators are engineered to provide the necessary rotation and stability required for effective excavation. Without a properly functioning swing bearing, an excavator’s performance can be severely compromised. The swing bearing is designed to handle heavy loads and harsh working conditions, making it a vital part of the excavator’s overall efficiency.

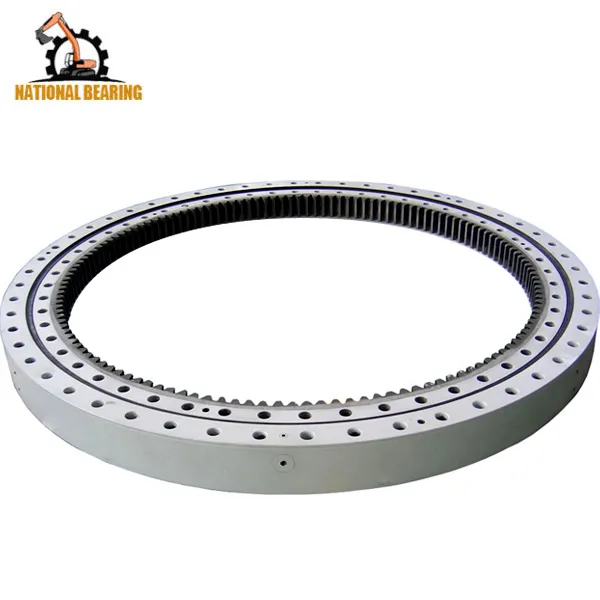

Inner Race

The inner race of a swing bearing is a cylindrical ring fixed to the excavator’s upper structure. This component plays a critical role in maintaining the alignment and stability of the bearing as it rotates, ensuring smooth and efficient movement. The inner race is constructed from high-strength materials, such as hardened steel or specialized alloys, to withstand the immense forces exerted during excavation operations. These materials are chosen for their durability and resistance to wear and tear, as the inner race must endure significant stress and pressure. In addition to its robust construction, the inner race must also be precisely machined to tight tolerances to ensure a perfect fit and optimal performance. This precision helps in minimizing any potential misalignment that could lead to uneven wear or premature failure of the swing bearing.

Outer Race

The outer race is a circular ring bolted to the lower structure of the excavator, forming the counterpart to the inner race. It works in conjunction with the inner race to provide a stable and reliable rotational movement for the excavator. The outer race must be securely fastened to the lower structure to ensure the integrity of the swing bearing and prevent any operational malfunctions. This secure attachment is typically achieved through the use of high-strength bolts or other fastening mechanisms designed to handle the dynamic loads encountered during excavation. Like the inner race, the outer race is also made from high-strength materials, designed to withstand the rigors of heavy-duty use. The outer race’s precision engineering and robust construction are essential for maintaining the overall stability and performance of the swing bearing.

롤링 요소

The rolling elements, which can be either balls or rollers, are placed between the inner and outer races, acting as the primary components that facilitate rotation. These elements are responsible for enabling smooth and controlled rotation by reducing friction between the moving parts. The rolling elements help to distribute the load evenly across the bearing, reducing localized stress and wear. This even distribution of load is crucial for the longevity and reliability of the swing bearing. The choice between balls or rollers depends on the specific requirements of the excavator and the type of work it performs. Ball bearings are typically used for applications requiring high-speed rotation and lower load capacities, while roller bearings are preferred for their ability to handle higher loads and provide greater stability. The selection of rolling elements is a critical design consideration that impacts the performance and durability of the swing bearing. In addition to their material composition and shape, the rolling elements must also be precisely manufactured and carefully assembled to ensure optimal function and minimize the risk of failure.

The primary function of a swing bearing is to provide a solid and reliable connection between the upper and lower structures of the excavator. This connection is vital for allowing the upper structure to rotate relative to the undercarriage efficiently and precisely. The stability offered by the swing bearing is crucial for maintaining the machine’s balance, especially during heavy-duty operations. By effectively distributing the excavator’s weight across the tracks, the swing bearing helps maximize stability, preventing tipping and ensuring safe operation even in challenging conditions. This even distribution of weight also minimizes stress on individual components, reducing wear and tear and prolonging the life of the excavator. Moreover, the swing bearing’s ability to manage and balance dynamic loads ensures that the excavator can handle heavy digging forces and complex movements without compromising its structural integrity or operational safety.

Another critical function of the swing bearing is to facilitate smooth and controlled movements during excavation tasks. This capability is essential for maintaining accuracy and minimizing downtime due to mechanical issues. A well-functioning swing bearing ensures that the excavator can perform precise and responsive movements, which is crucial for tasks requiring a high degree of accuracy, such as trenching, grading, and precision digging. The smooth operation provided by the swing bearing reduces operator fatigue and enhances the overall efficiency of the excavation process. Additionally, controlled movements help in avoiding sudden jerks or disruptions that could lead to material spillage or damage to the worksite. The ability of the swing bearing to maintain consistent performance under varying loads and conditions is a testament to its engineering excellence, ensuring that the excavator remains a versatile and reliable tool across different projects and environments.

The swing bearing also plays a significant role in enhancing the durability and overall performance of the excavator. By ensuring that the rotational movements are smooth and frictionless, the swing bearing minimizes the mechanical stress on the moving parts. This reduction in stress not only improves the machine’s operational efficiency but also extends the lifespan of critical components. Regular maintenance and proper lubrication of the swing bearing are essential practices that further enhance its durability. The use of high-quality materials in the construction of swing bearings, such as hardened steel or specialized alloys, ensures that they can withstand the harsh conditions of excavation work. This durability is critical for maintaining the excavator’s performance over time, reducing the frequency of repairs and replacements, and ensuring that the machine remains operational and productive for longer periods.

Versatility and Adaptability

Swing bearings contribute to the versatility and adaptability of excavators by enabling them to perform a wide range of tasks with precision and efficiency. The ability to rotate the upper structure independently of the undercarriage allows operators to maneuver the excavator in confined spaces and navigate complex work environments with ease. This flexibility is particularly beneficial in urban construction sites, mining operations, and other settings where space and movement are restricted. The swing bearing’s design also allows for the integration of various attachments and tools, further expanding the excavator’s capabilities. Whether it’s using a hydraulic hammer for demolition, a grappler for material handling, or an auger for drilling, the swing bearing ensures that each attachment can be used effectively, enhancing the machine’s overall functionality and productivity.

By understanding these critical functions, operators and maintenance personnel can better appreciate the importance of swing bearings in excavators and take appropriate measures to ensure their optimal performance and longevity.

Regular inspection of the swing bearing is crucial to ensure maximum performance and longevity of the excavator. It is recommended to check for signs of wear, such as unusual noises, vibrations, or visible damage. Regular inspections can help identify potential issues before they result in significant downtime or costly repairs.

Proper lubrication is essential for the smooth operation of the swing bearing. Swing bearings, which facilitate the rotational movement of heavy machinery like excavators, rely heavily on lubrication to function efficiently. Without adequate lubrication, the friction between the rolling elements and the races increases, leading to excessive wear and tear. This friction not only degrades the bearing surfaces but also generates heat, which can further damage the components and lead to premature failure.

Lubrication reduces friction between the rolling elements and the races, preventing excessive wear and tear. The lubricant acts as a protective barrier, minimizing direct metal-to-metal contact and distributing the load more evenly across the bearing surfaces. This results in smoother operation, less noise, and reduced vibration, all of which contribute to the longevity of the swing bearing.

It is important to use the correct type of lubricant and follow the manufacturer’s recommendations for lubrication intervals. The type of lubricant can vary depending on the bearing’s design, operating conditions, and the specific requirements of the machinery. Some bearings may require grease, while others might need oil-based lubricants. Using the wrong lubricant can compromise the bearing’s performance and lead to accelerated wear.

Following the recommended lubrication intervals is equally crucial. Over-lubrication or under-lubrication can both lead to problems. Over-lubrication can cause the lubricant to leak, attracting dirt and contaminants that can damage the bearing. Under-lubrication, on the other hand, can result in insufficient protection against friction and wear. Therefore, adhering to the manufacturer’s guidelines ensures that the bearing receives the right amount of lubrication at the right times, maintaining optimal performance and extending its service life.

Regularly checking the lubrication levels and reapplying lubricant as needed is a key part of maintenance. This proactive approach helps in identifying potential issues early and addressing them before they lead to significant damage. Proper lubrication practices not only enhance the performance of the swing bearing but also contribute to the overall efficiency and reliability of the machinery.

Even with regular maintenance, swing bearings will eventually wear out and need to be replaced. Over time, the constant rotation and load-bearing functions cause wear and tear on the swing bearing, leading to diminished performance. It is important to replace the swing bearing at the first sign of significant wear to prevent further damage to the excavator. Early signs of wear might include unusual noises, increased vibration, or difficulty in the smooth rotation of the upper structure. Replacing the swing bearing in a timely manner can help maintain the efficiency and performance of the excavator. Ignoring these signs can lead to more severe mechanical failures, potentially causing downtime and costly repairs. A well-timed replacement not only ensures continued operational efficiency but also extends the lifespan of the excavator. Therefore, monitoring the condition of the swing bearing and scheduling replacements as needed is crucial for the optimal functioning and longevity of the machine.

Swing bearings for excavators are a critical component that ensures the stability and smooth operation of the machine. Understanding the key components and functions of swing bearings can help operators and maintenance personnel ensure that their excavators perform at their best. Regular maintenance, including inspection, lubrication, and timely replacement, is essential for maximizing the performance and longevity of swing bearings. By taking proper care of their swing bearings, operators can ensure that their excavators remain reliable and efficient, even in the most demanding conditions.