In the world of engineering, gears and slewing rings are indispensable components that play crucial roles in various applications. These essential parts are responsible for transmitting power, facilitating rotation, and supporting heavy loads across diverse industries, including automotive, aerospace, mining, and manufacturing. To withstand demanding conditions and ensure their longevity and performance, hardening solutions for these components have become essential. This blog explores the significance of gear and slewing ring hardening, delving into the techniques that enhance their durability, wear resistance, fatigue strength, and overall efficiency. By understanding these processes, we can better appreciate how they contribute to the reliable operation of complex machinery.

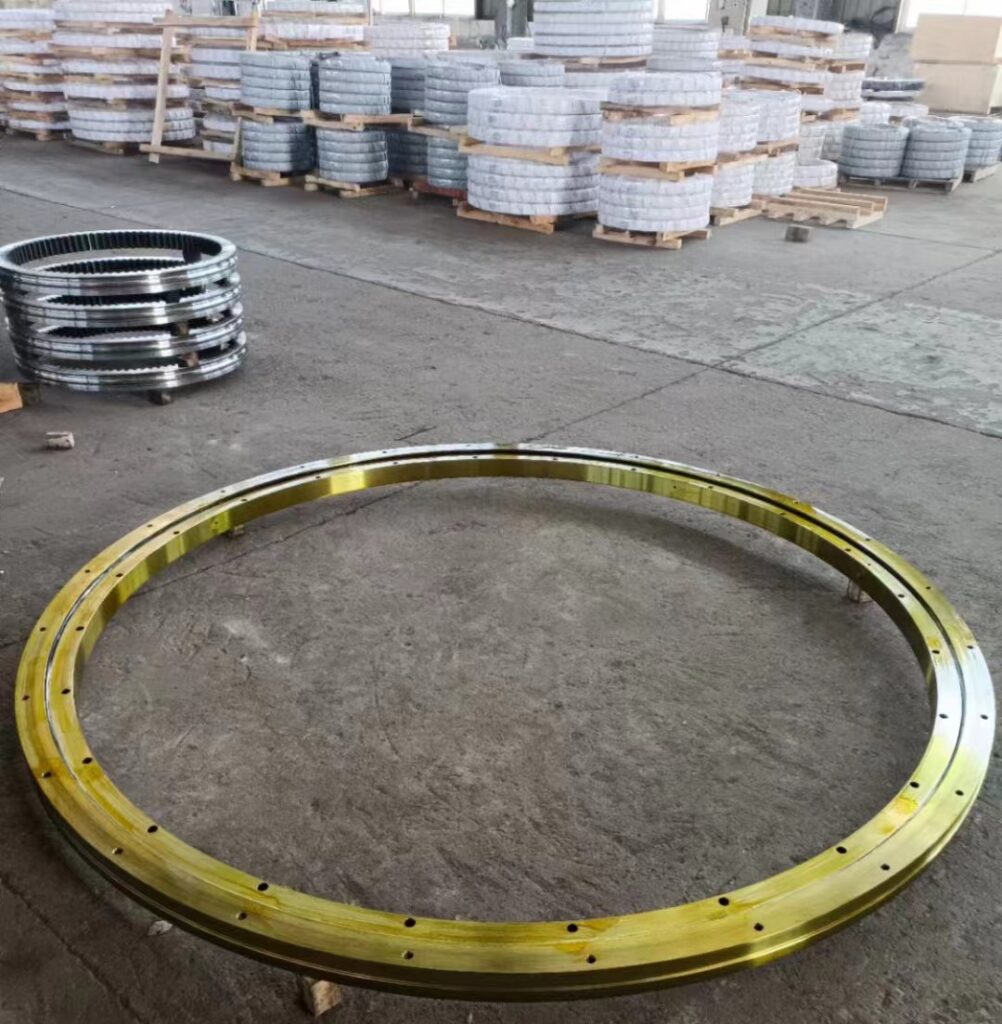

Gears and slewing rings, also known as turntable bearings, are subjected to extreme loads, continuous rotation, and wear. Gears transmit rotational motion and torque between shafts, facilitating the smooth operation of various machinery. Slewing rings enable smooth rotation in heavy machinery, cranes, wind turbines, and other applications. Due to their critical functions, these components must withstand harsh operational environments. Hardening them increases their durability, improves wear resistance, and enhances overall performance. Ensuring that these parts are properly hardened is crucial for maintaining the efficiency and safety of the machines they are part of, thus preventing unexpected failures and costly downtime.

Induction hardening is a popular technique that rapidly heats the surface of a gear or slewing ring using electromagnetic waves. The heated area is then quickly quenched, resulting in a hardened outer layer known as the “case.” This method provides excellent wear resistance and surface hardness while maintaining the core’s toughness. Induction hardening is particularly beneficial for components subjected to high stress and wear, as it creates a strong, durable surface capable of withstanding harsh conditions. The precision of induction hardening allows for targeted treatment of specific areas, ensuring that the most vulnerable parts of the component receive the necessary protection.

Carburizing involves heating the gear or slewing ring in a carbon-rich atmosphere, allowing carbon atoms to diffuse into the surface. After carburizing, the component is quenched and tempered to achieve the desired hardness and core strength. This technique is highly effective in enhancing wear resistance, making it suitable for components that experience significant friction and wear during operation. The carburizing process not only hardens the surface but also strengthens the core, providing a balanced combination of toughness and hardness. This makes carburized components ideal for applications where both strength and wear resistance are critical.

Nitriding introduces nitrogen into the component’s surface layer in a nitrogen-rich environment at low temperatures. This process forms a hard compound layer on the surface, enhancing wear resistance, fatigue strength, and corrosion resistance. Nitriding is ideal for applications requiring exceptional surface hardness and durability without compromising the core’s toughness. The lower processing temperatures used in nitriding reduce the risk of component distortion, making it a preferred method for precision parts. Additionally, the nitrogen compounds formed on the surface provide excellent protection against wear and corrosion, extending the component’s service life.

Flame hardening is suitable for large gears and slewing rings. A high-intensity flame is directed at specific areas of the component’s surface, and the heated areas are then quenched to create a hardened layer. This localized hardening technique provides targeted hardness while preserving the core’s toughness, making it ideal for large and heavy-duty components. Flame hardening allows for flexibility in treating only the necessary areas, which can be more efficient and cost-effective compared to full surface hardening. The process is particularly useful for large components where uniform heating and quenching might be challenging.

Case hardening encompasses techniques like carburizing and nitriding, aiming to create a hardened outer layer with a tougher core. This method is effective for components requiring both wear resistance and impact strength. By hardening the surface while maintaining a resilient core, case hardening ensures the component can withstand harsh operational conditions. The combination of a hard exterior and a tough interior provides a balanced solution for components that face both high wear and significant mechanical stresses. This dual-layer structure helps extend the lifespan of the parts, ensuring reliable performance over prolonged use.

In through hardening, the entire gear or slewing ring is uniformly heated and then quenched to achieve consistent hardness throughout the component. While it lacks the localized hardening benefits, through hardening is suitable for applications where uniform hardness is essential. This technique ensures that the component can withstand uniform stress and wear. Through hardening provides a straightforward and effective means of increasing the overall strength of the component, making it ideal for applications where comprehensive hardness is more beneficial than localized treatment.

Choosing the right hardening technique depends on factors such as application requirements, load conditions, and material properties. For example, components operating under high-load conditions may benefit from induction hardening or carburizing, while those requiring excellent wear resistance might be treated with nitriding or flame hardening. Understanding these factors ensures the selection of the most suitable hardening method, optimizing the performance and longevity of gears and slewing rings. Engineers must consider the specific demands of each application to determine the best hardening process, balancing cost, effectiveness, and the operational environment to achieve optimal results.

Gear and slewing ring hardening solutions are crucial for ensuring the longevity and efficiency of these vital components. By selecting the appropriate hardening technique, engineers can significantly enhance the performance, strength, and reliability of gears and slewing rings. As technology advances and engineering challenges continue to grow, the importance of gear and slewing ring hardening will only increase, making it a critical aspect of modern engineering practices. Ensuring that these components are properly hardened not only extends their lifespan but also contributes to the overall safety, reliability, and efficiency of the machinery they are part of.

Q1: What is the primary purpose of hardening gears and slewing rings?

Q2: How does induction hardening benefit gears and slewing rings?

Q3: What are the advantages of carburizing as a hardening technique?

Q4: Why is nitriding preferred for certain applications?

Q5: How does through hardening differ from other hardening techniques?

Q6: What factors should be considered when selecting a hardening technique?