When it comes to the efficient and smooth operation of heavy machinery like excavators, every component plays a crucial role. Among these components, swing bearings are paramount. In this blog, we will delve into the specifics of the Caterpillar Excavator E200B swing bearing, discussing its significance, the reasons to choose a particular brand, and the best practices for maintenance and replacement. By the end of this guide, you will have a comprehensive understanding of why the E200B swing bearing is critical to your excavator’s performance.

Swing bearings, also known as slewing bearings or turntable bearings, are pivotal in the functionality of an excavator. These bearings facilitate the smooth rotation of the excavator’s upper structure, allowing it to swing from side to side. This rotational capability is essential for the excavator’s maneuverability and efficiency in performing tasks such as digging, lifting, and placing materials.

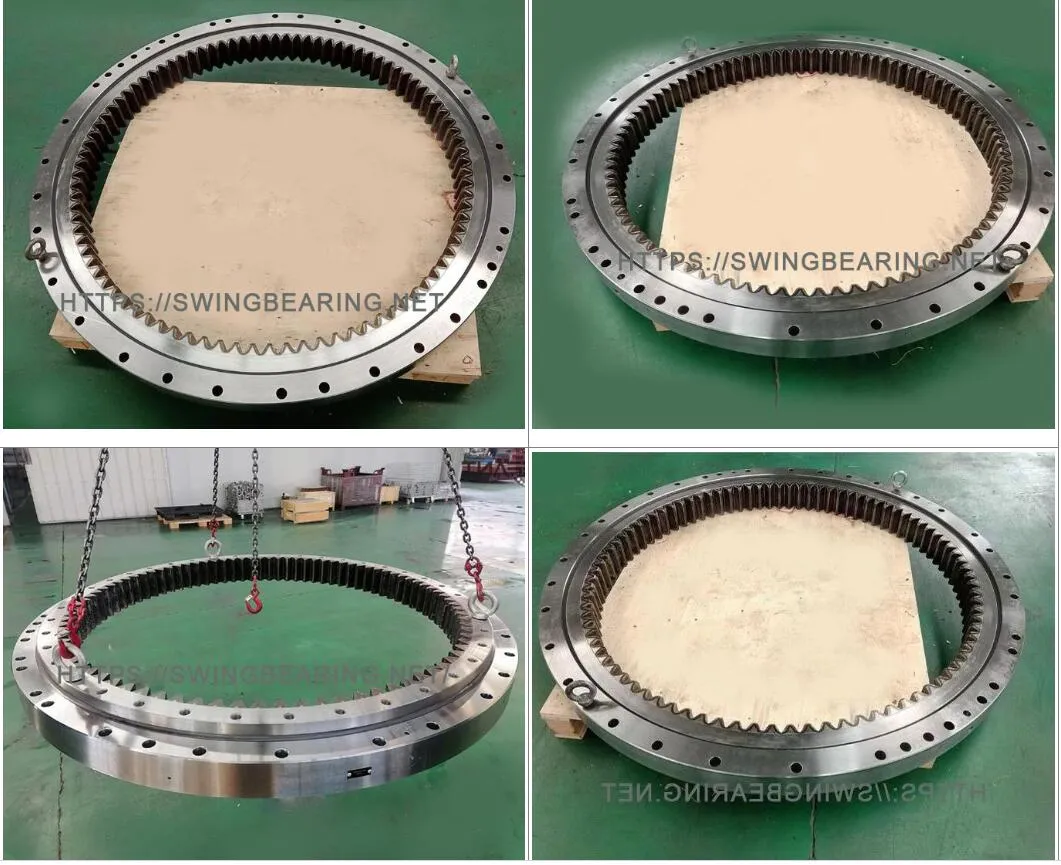

The swing bearing for the Caterpillar Excavator E200B, identified by Part # 085-7964, is designed specifically to meet the demanding needs of this model. Here are some key specifications and features:

The weight and design of the swing bearing are crucial. At 582 lbs, this bearing is robust enough to handle the stresses and strains of daily excavation work. It ensures durability and reliability, two essential qualities for any heavy machinery component. The compatibility with the E200B model means that it is tailored to fit perfectly, ensuring optimal performance.

The construction of the swing bearing involves high-grade materials designed to withstand extreme conditions. Typically, these bearings are made from hardened steel, which provides excellent wear resistance and longevity. The precision engineering ensures that the bearing can handle both radial and axial loads efficiently.

Each swing bearing undergoes rigorous testing to ensure it meets the highest standards of quality and durability. This includes load testing, stress analysis, and fatigue testing. These tests ensure that the bearing can withstand the heavy loads and repetitive movements typical of excavation work.

The E200B swing bearing is built to last, even in the harshest environments. Whether it’s operating in extreme temperatures, handling heavy loads, or dealing with dirt and debris, this bearing is designed to perform consistently. Regular maintenance and proper usage can further extend its lifespan, ensuring you get the most value out of your investment.

Ensuring that your swing bearings are delivered securely and on time is crucial. Any damage during transit can compromise the integrity of the bearing, leading to potential failures and costly downtime.

Our freight shipping process is designed to minimize the risk of damage and ensure timely delivery. Each bearing is carefully packaged to protect it from impacts and vibrations during transit. We work with reliable shipping partners to ensure that your order arrives safely and on schedule.

By ensuring efficient and secure shipping, we help you minimize downtime. When your swing bearing arrives in perfect condition and on time, you can get your excavator back to work quickly, maintaining productivity and reducing costs associated with delays.

Our swing bearings are specifically designed for the Caterpillar E200B excavator. This means they are a perfect fit, ensuring optimal performance and longevity. Using bearings that are tailored for your specific model eliminates the risks associated with using generic parts, such as improper fitting or premature wear.

The bearings replace part numbers 085-7964 and 856757. This compatibility ensures that you are getting a part that meets or exceeds the original equipment manufacturer (OEM) specifications. It also means you can trust that the bearing will work seamlessly with your existing setup.

굴착 작업의 까다로운 조건을 견딜 수 있도록 제작된 스윙 베어링은 내구성과 신뢰성을 모두 제공합니다. 고품질 소재를 사용하고 엄격한 테스트를 거쳐 일상적인 작업에서 발생하는 압력과 스트레스를 견딜 수 있는 베어링입니다.

스윙 베어링의 성능과 수명을 유지하려면 정기적인 점검과 윤활이 필수적입니다. 마모, 부식 또는 손상 징후가 있는지 확인하세요. 마찰과 마모를 줄이기 위해 베어링이 적절하게 윤활되어 있는지 확인하세요.

구멍, 갈라짐, 변색 등 눈에 보이는 마모 징후가 있는지 살펴보세요. 작동 중 내부 손상을 나타낼 수 있는 비정상적인 소음이 들리지 않는지 살펴봅니다. 마모를 조기에 발견하면 더 심각한 손상과 값비싼 수리를 방지할 수 있습니다.

스윙 베어링에 권장되는 윤활제를 사용하세요. 제조업체의 지침에 따라 윤활제를 골고루 도포하세요. 정기적으로 윤활유를 바르면 마찰과 마모, 베어링 고장의 위험을 줄일 수 있습니다.

성공적인 설치를 위해서는 적절한 준비가 중요합니다. 작업 공간이 깨끗하고 오염 물질이 없는지 확인하세요. 설치 프로세스를 시작하기 전에 필요한 모든 도구와 장비를 준비하세요.

설치 후에는 베어링이 제대로 고정되고 올바르게 작동하는지 철저히 점검하세요. 정렬이 잘못되었거나 결합된 흔적이 있는지 확인합니다. 설치 후 정기적으로 점검하면 향후 문제를 예방하고 베어링의 수명을 연장하는 데 도움이 될 수 있습니다.

Swing bearings are critical components in the operation of Caterpillar Excavators, particularly the E200B model. The Part # 085-7964 swing bearing, tailored specifically for this excavator, offers durability, reliability, and optimal performance. Ensuring proper maintenance, timely inspection, and correct installation are key to maximizing the lifespan and efficiency of these bearings. By choosing high-quality, compatible parts and following best practices for care, you can keep your excavator running smoothly and efficiently.

A: 스윙 베어링 교체가 필요하다는 신호에는 작동 중 비정상적인 소음, 눈에 보이는 마모 또는 손상, 마찰 증가, 굴삭기 상부 구조의 회전이 어려운 경우 등이 있습니다. 정기적인 점검을 통해 이러한 징후를 조기에 발견할 수 있습니다.

A: 매일 정기 점검을 실시하고 적어도 한 달에 한 번은 철저히 점검해야 합니다. 윤활은 제조업체의 권장 사항에 따라 일반적으로 100~200시간마다 또는 열악한 조건에서는 더 자주 수행해야 합니다.

A: 필요한 도구와 전문 지식이 있다면 스윙 베어링을 직접 설치할 수도 있지만, 전문가를 고용하는 것이 좋습니다. 적절한 설치는 베어링의 성능과 수명을 보장하는 데 매우 중요하며, 전문가가 올바르게 설치했는지 확인할 수 있습니다.

A: 스윙 베어링에 제조업체의 사양을 충족하는 고품질 윤활제를 사용하세요. 일반적으로 고부하, 고속 애플리케이션용으로 설계된 고강도 그리스를 사용합니다. 구체적인 권장 사항은 장비의 설명서를 참조하세요.

A: The weight of the swing bearing, such as the 582 lbs for the Caterpillar E200B, indicates its robustness and ability to handle the stresses of excavation work. A heavier bearing typically offers greater durability and reliability, ensuring long-lasting performance under heavy loads.