A slew ring is a crucial component found on excavators and other heavy machinery. It is a rotating ring that allows the machine’s superstructure to pivot and rotate, enabling the excavator to move in various directions. The slew ring is designed to withstand the heavy loads and high torque generated by the excavator’s movements, ensuring smooth and precise operation. It is made of high-quality materials, such as steel and bearings, to provide durability and long-lasting performance. In summary, the slewing ring is an essential part of an excavator that enables it to rotate and maneuver effectively in various working conditions.

The slewing ring on an excavator is a crucial component that plays a significant role in the smooth operation of the machine. It is a bearing system that allows the excavator’s superstructure to rotate, enabling the operator to control the direction in which the excavator’s arm and bucket move. In this article, we will delve into the importance of slew rings and how they contribute to the overall functionality of an excavator.

Firstly, it is essential to understand the structure of an excavator. The machine consists of a cab, a chassis, and a superstructure. The cab houses the operator, while the chassis provides the foundation for the entire machine. The superstructure, on the other hand, is the part that contains the arm and bucket, which are responsible for digging and moving materials. The slewing ring is located at the base of the superstructure and is connected to the chassis.

The slewing ring is designed to withstand the immense forces generated during excavation work. It is made up of a series of bearings that are enclosed within a ring-shaped housing. These bearings are typically made of high-quality materials such as steel or bronze, which provide both strength and durability. The housing is then filled with a lubricant, which helps to reduce friction and wear between the moving parts of the ring.

One of the primary functions of the slewing ring is to facilitate the smooth rotation of the superstructure. As the operator controls the excavator’s arm and bucket, the superstructure must be able to rotate seamlessly to follow the desired direction. The slew ring ensures that this rotation is smooth and precise, allowing the operator to maintain control over the machine even when working in tight spaces or on uneven terrain.

Another critical role of the slewing ring is to absorb and distribute the forces generated during excavation work. When the excavator’s arm and bucket are used to dig or move materials, significant forces are applied to the superstructure. The slewing ring is designed to absorb these forces and distribute them evenly across the bearings, preventing damage to the machine and ensuring its longevity.

In addition to its functional benefits, the slewing ring also plays a vital role in the overall safety of the excavator. The smooth rotation provided by the slew ring allows the operator to maintain control over the machine at all times, reducing the risk of accidents or injuries. Furthermore, the ability of the slew ring to absorb and distribute forces helps to prevent structural damage to the excavator, ensuring that it remains safe and reliable for use.

In conclusion, the slewing ring on an excavator is a critical component that contributes significantly to the machine’s overall functionality and safety. By facilitating smooth rotation and absorbing and distributing forces, the slewing ring ensures that the excavator can operate efficiently and effectively, even in challenging conditions. As such, it is essential for operators and maintenance personnel to understand the importance of the slew ring and to take appropriate measures to ensure its proper functioning and maintenance.

The slew ring on an excavator is a crucial component that plays a significant role in the overall performance and efficiency of the machine. It is responsible for allowing the excavator’s superstructure to rotate smoothly and accurately, enabling the operator to control the direction and movement of the machine with precision. In this article, we will delve into the importance of slew ring maintenance for excavator performance and discuss the various factors that contribute to its optimal functioning.

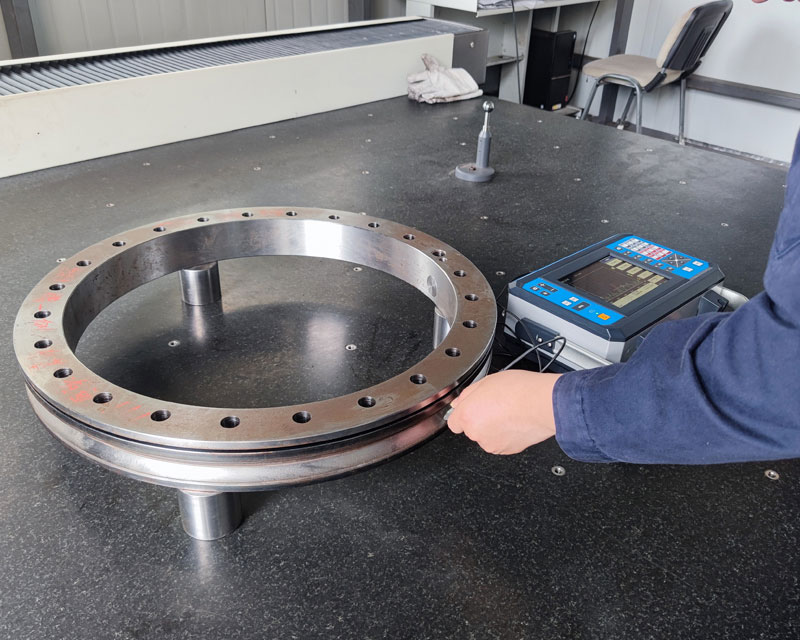

The slewing ring is a bearing system that consists of a ring-shaped housing, inner and outer races, and rolling elements such as balls or rollers. These components are designed to withstand the heavy loads and high torques generated by the excavator’s superstructure during operation. The slew ring is subjected to continuous wear and tear due to the friction between the moving parts, which can lead to reduced performance, increased vibrations, and even failure if not properly maintained.

One of the primary factors that contribute to the optimal functioning of the slew ring is the quality of its materials and design. High-quality materials, such as steel or bronze, are used to manufacture the slew ring components to ensure durability and resistance to wear. Additionally, the design of the slewing ring should allow for proper lubrication and cooling of the moving parts, which helps to reduce friction and prolong the life of the components.

Another important aspect of slew ring maintenance is regular inspection and lubrication. The slew ring should be inspected at regular intervals to check for signs of wear, damage, or excessive play in the bearing system. Any issues that are identified during the inspection should be addressed promptly to prevent further damage and ensure the continued smooth operation of the excavator.

Lubrication is essential for maintaining the slew ring’s performance, as it helps to reduce friction between the moving parts and dissipate heat generated during operation. The slew ring should be lubricated according to the manufacturer’s recommendations, which typically involve applying a grease or oil specifically designed for use in heavy-duty applications. Regular lubrication helps to prolong the life of the slew ring components and ensures that the excavator operates smoothly and efficiently.

In addition to regular inspection and lubrication, the slew ring should also be properly aligned to ensure that the excavator’s superstructure rotates smoothly and accurately. Misalignment can cause excessive wear on the slew ring components and lead to reduced performance and increased vibrations. The alignment of the slew ring should be checked and adjusted as needed to maintain the optimal functioning of the excavator.

In conclusion, the slew ring on an excavator is a critical component that plays a vital role in the overall performance and efficiency of the machine. Proper maintenance of the slew ring, including regular inspection, lubrication, and alignment, is essential for ensuring that the excavator operates smoothly and accurately. By paying attention to these maintenance requirements, operators can extend the life of the slew ring components and maintain the optimal performance of their excavator.

The slew ring on an excavator is a crucial component that enables the machine to rotate smoothly and efficiently. It is a bearing system that supports the rotation of the excavator’s superstructure, which houses the cab and the engine. The slew ring is a circular ring made of steel or cast iron, with a series of rollers or balls that allow the superstructure to rotate around the excavator’s axis. This rotation is essential for the excavator to perform its primary function, which is to dig, move, and lift materials.

The slew ring is subjected to significant stress and wear due to the heavy loads and constant movement of the excavator. As a result, it is essential to maintain and replace the slew ring as needed to ensure the continued smooth operation of the excavator. One of the most common issues with slew rings is the accumulation of dirt and debris, which can cause the ring to become misaligned or even seize up. Regular cleaning and lubrication of the slew ring can help prevent these issues and extend the life of the component.

Over the years, slewing ring technology has evolved to meet the increasing demands of the construction and mining industries. Early excavators used simple bearing systems, such as ball bearings or plain bearings, which were prone to wear and required frequent maintenance. However, these systems were sufficient for the relatively light loads and slower speeds of early excavators.

As excavators became larger and more powerful, the need for more robust and reliable slew ring systems became apparent. In response, manufacturers began to develop more advanced bearing systems, such as roller bearings and tapered roller bearings. These systems offered improved load-carrying capacity and durability, allowing excavators to handle heavier loads and operate at higher speeds.

More recent advancements in slew ring technology have focused on improving the efficiency and longevity of the component. For example, some modern slew rings use sealed bearing systems that prevent the ingress of dirt and debris, reducing the need for maintenance and extending the life of the component. Additionally, some slew rings are now made from advanced materials, such as composite materials or high-strength steel alloys, which offer improved wear resistance and durability.

In conclusion, the slewing ring on an excavator is a vital component that enables the machine to rotate smoothly and efficiently. Over the years, slew ring technology has evolved to meet the increasing demands of the construction and mining industries, with advancements in bearing systems, materials, and sealing technologies. As a result, modern excavators are now capable of handling heavier loads and operating at higher speeds than ever before, making them more productive and efficient tools for the jobsite.

The slew ring on an excavator is a critical component that allows the machine to rotate its superstructure, or the part that includes the cab, arm, and bucket. The slew ring is a large, circular bearing that supports the weight of the superstructure and enables smooth rotation. It is made up of an outer ring, an inner ring, and a set of rolling elements, such as balls or rollers, that reduce friction and allow for easy rotation. The slew ring is essential for the excavator’s operation, as it enables the machine to perform tasks such as digging, grading, and lifting materials efficiently and accurately.