In the world of heavy machinery, particularly excavators and other construction equipment, terms like “travel motor,” “final drive,” and “hydraulic motor” are often used interchangeably. However, they refer to different components, each with distinct functions and characteristics. Understanding these differences is crucial for proper maintenance, troubleshooting, and optimizing the performance of your machinery. This blog will delve into the specifics of each component, highlighting their unique roles, how they interconnect, and the detailed operation steps involved in maintaining them.

A travel motor is a type of hydraulic motor that powers the movement of an excavator or other tracked equipment. It converts hydraulic pressure into mechanical energy, enabling the tracks to rotate and propel the machine forward or backward. Travel motors are integral to the mobility of the machinery and are designed to withstand the high loads and harsh conditions encountered on construction sites.

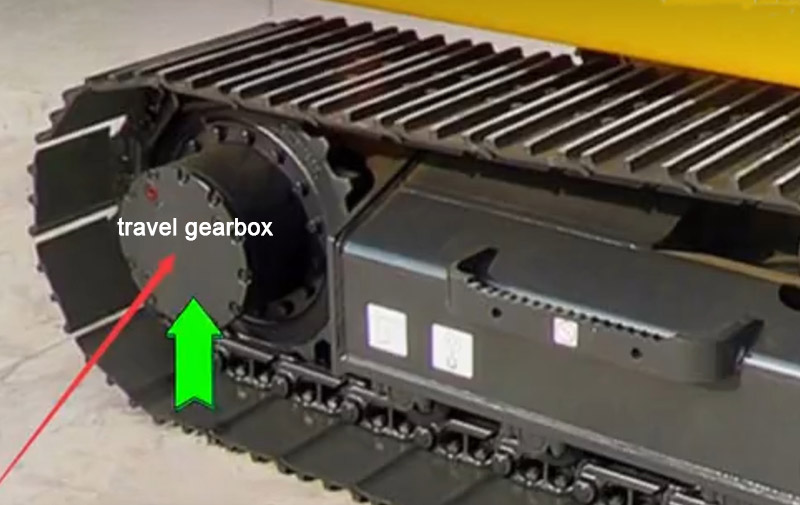

The final drive is the last stage in the power transmission chain of an excavator, transferring the rotational force from the travel motor to the tracks. It comprises a planetary gear system that reduces the speed of the motor’s output while increasing torque, enabling the machine to move efficiently and handle heavy loads.

A hydraulic motor is a mechanical actuator that converts hydraulic energy into mechanical force and motion. It operates on the principle of fluid dynamics, utilizing pressurized hydraulic fluid to produce rotational or linear motion. Hydraulic motors are used in various applications within an excavator, including the operation of the boom, arm, and bucket, in addition to powering the travel motor.

Travel motors, final drives, and motori idraulici each play crucial roles in the operation of heavy machinery, particularly excavators. Travel motors convert hydraulic pressure into mechanical energy to move the tracks, while final drives reduce speed and increase torque to propel the machine efficiently. Hydraulic motors, on the other hand, are versatile actuators that convert hydraulic energy into mechanical motion for various applications within the machinery.

Understanding the distinct functions and maintenance requirements of these components is essential for ensuring optimal performance and longevity of your equipment. Regular inspections, proper lubrication, and adherence to manufacturer guidelines can significantly reduce the risk of failures and extend the operational life of these critical components.

Signs of a failing travel motor include reduced speed, unusual noises (such as grinding or knocking), oil leaks, and overheating. Regular inspections and timely maintenance can help identify and address these issues before they lead to significant damage.

The final drive oil should typically be changed every 1,000 operating hours or as recommended by the manufacturer. Regular oil changes ensure that the gears and bearings are properly lubricated and protected from wear and contamination.

Hydraulic motors can often be repaired by replacing worn components such as seals, bearings, and gears. However, severe damage or extensive wear may necessitate a complete replacement. Regular maintenance and using high-quality hydraulic fluid can help prolong the life of the hydraulic motor.

The best type of lubrication for final drives is typically a high-quality gear oil that meets the manufacturer’s specifications. This oil should have the appropriate viscosity and contain additives that protect against wear, corrosion, and extreme pressure.

To improve the longevity of your travel motor, perform regular maintenance checks, use the recommended hydraulic fluid, ensure proper filtration to keep the fluid clean, and address any leaks or unusual noises promptly. Additionally, operating the excavator within its designed parameters and avoiding excessive loads can help reduce stress on the travel motor.