Parti di escavatori tracking and monitoring for maintenance schedules is a crucial aspect of ensuring the smooth operation and longevity of excavators. This process involves the use of advanced technologies and systems to keep track of various components and their performance, enabling timely maintenance and reducing the risk of unexpected breakdowns. In this article, we will discuss the methods and techniques used to track and monitor excavator parts for maintenance purposes.

One of the primary methods of tracking and monitoring excavator parts is through the use of sensors and data loggers. These devices are installed on critical components such as engines, hydraulic systems, and transmissions, and they continuously monitor the performance and condition of these parts. The data collected by these sensors is then transmitted to a central system, where it can be analyzed to identify potential issues and schedule maintenance accordingly.

Another method of tracking excavator parts is through the use of GPS technology. GPS devices can be installed on excavators to track their location and movement, as well as to monitor the usage of the machine. This information can be used to determine the wear and tear on various parts and to schedule maintenance accordingly.

Komatsu PC1250-8 Main Pump 708-2L-00680

In addition to sensors and GPS technology, excavator manufacturers often provide their own monitoring systems and software. These systems can be integrated with the excavator’s onboard systems to provide real-time data on the performance and condition of various components. This information can be used by the operator or maintenance personnel to schedule maintenance and ensure that the excavator is operating at peak efficiency.

Finally, some excavator operators choose to use third-party monitoring services to track and monitor their machines. These services provide a comprehensive solution for tracking and monitoring excavator parts, including data analysis, maintenance scheduling, and even predictive maintenance capabilities.

In conclusion, tracking and monitoring excavator parts for maintenance schedules is an essential aspect of maintaining the performance and longevity of these machines. By using a combination of sensors, GPS technology, manufacturer-provided systems, and third-party services, excavator operators can ensure that their machines are operating at peak efficiency and that maintenance is scheduled in a timely and cost-effective manner.

The Role of IoT in Tracking and Monitoring Excavator Parts

In the modern world, technology has become an indispensable tool for various industries, including the construction sector. One of the most significant advancements in this field is the Internet of Things (IoT), which has revolutionized the way excavator parts are tracked and monitored for maintenance schedules. This article will delve into the role of IoT in this process and how it has improved efficiency and productivity in the construction industry.

IoT refers to the network of physical devices, vehicles, and appliances embedded with sensors, software, and network connectivity, which enables them to collect and exchange data. In the context of excavators, IoT technology is used to monitor various components and systems, such as engines, hydraulic systems, and electronic control units. By continuously gathering data on the performance and condition of these parts, IoT enables real-time tracking and monitoring of excavator parts, allowing for more accurate and timely maintenance schedules.

One of the primary benefits of IoT in tracking and monitoring excavator parts is the ability to predict potential failures before they occur. By analyzing the data collected from sensors, IoT systems can identify patterns and trends that may indicate an impending malfunction. This early warning system allows maintenance teams to address issues proactively, reducing the likelihood of unexpected breakdowns and minimizing downtime.

Another advantage of IoT technology in this context is the improved efficiency in resource allocation. Traditional maintenance schedules often involve routine inspections and preventive measures, which can be time-consuming and costly. With IoT, maintenance teams can focus their efforts on parts that require attention, optimizing the use of resources and reducing overall maintenance costs.

Moreover, IoT technology has enabled the development of advanced analytics and machine learning algorithms that can process the vast amounts of data collected from excavator parts. These algorithms can identify correlations between different variables, such as temperature, pressure, and vibration, to provide insights into the overall health of the excavator. This information can be used to optimize maintenance schedules, ensuring that parts are replaced or serviced at the most appropriate times.

Furthermore, IoT technology has facilitated remote monitoring of excavator parts, allowing maintenance teams to keep track of their equipment from anywhere in the world. This feature is particularly useful for construction companies with multiple excavators operating in different locations. Remote monitoring not only saves time and resources but also allows for quicker response times in case of emergencies.

In conclusion, the role of IoT in tracking and monitoring excavator parts has significantly improved the efficiency and productivity of the construction industry. By enabling real-time data collection, predictive maintenance, and remote monitoring, IoT technology has transformed the way excavator parts are maintained, reducing downtime and costs while ensuring optimal performance. As IoT continues to evolve, it is expected that its impact on the construction sector will only grow, further revolutionizing the way we approach maintenance and management of excavator parts.

Excavator parts are essential components of the heavy machinery used in various industries, such as construction, mining, and agriculture. These parts are subject to wear and tear, and regular maintenance is crucial to ensure their optimal performance and longevity. In this article, we will discuss how excavator parts are tracked and monitored for maintenance schedules, highlighting the importance of regular maintenance in preventing costly repairs and downtime.

Excavator parts can be tracked and monitored using a combination of technologies, including GPS tracking, sensors, and software systems. GPS tracking allows operators and maintenance teams to monitor the location and movement of the excavator, ensuring that it is used within designated areas and preventing unauthorized use. Sensors are installed on various parts of the excavator, such as the engine, hydraulic system, and tracks, to monitor their performance and detect any anomalies that may indicate a need for maintenance.

Software systems are used to collect and analyze data from the sensors and GPS tracking devices, providing real-time information on the excavator’s performance and the condition of its parts. This data is used to create maintenance schedules that are tailored to the specific needs of each excavator, taking into account factors such as usage patterns, environmental conditions, and the age of the parts.

Regular maintenance schedules are essential for ensuring the optimal performance of excavator parts. By monitoring the condition of these parts and performing maintenance when necessary, operators can prevent costly repairs and downtime. Additionally, regular maintenance can extend the lifespan of the excavator’s parts, reducing the overall cost of ownership.

One of the key benefits of tracking and monitoring excavator parts is the ability to predict and prevent failures. By analyzing the data collected from sensors and software systems, maintenance teams can identify potential issues before they become critical, allowing them to perform preventive maintenance and avoid unexpected breakdowns. This not only saves time and money but also ensures that the excavator remains operational and productive.

Another benefit of regular maintenance schedules is the improvement in the overall safety of the excavator. Well-maintained parts are less likely to fail, reducing the risk of accidents and injuries. Additionally, regular maintenance can help to identify any safety hazards, such as worn or damaged parts, that could potentially cause harm to operators and bystanders.

In conclusion, tracking and monitoring excavator parts for maintenance schedules is a crucial aspect of ensuring the optimal performance and longevity of these heavy machinery components. By using a combination of GPS tracking, sensors, and software systems, operators can create tailored maintenance schedules that prevent costly repairs and downtime, improve safety, and extend the lifespan of the excavator’s parts. Regular maintenance is not only essential for the smooth operation of excavators but also for the overall success of the industries that rely on this heavy machinery.

In the modern era of technology, the construction industry has witnessed a significant transformation, with excavators being no exception. The integration of advanced technologies has revolutionized the way excavator parts are tracked and monitored for maintenance schedules. This article delves into the various methods employed to ensure that excavator parts are maintained in optimal condition, thereby enhancing the overall efficiency and productivity of the equipment.

One of the most prominent methods of tracking and monitoring excavator parts is through the use of sensors and IoT (Internet of Things) technology. These sensors are strategically placed on critical components of the excavator, such as the engine, hydraulic system, and undercarriage. They continuously collect data on the performance and condition of these parts, which is then transmitted to a centralized system for analysis. This data-driven approach allows for proactive maintenance, as it enables operators to identify potential issues before they escalate into major problems.

Another innovative method of tracking and monitoring excavator parts is through the use of GPS technology. GPS devices are installed on the excavator, allowing for real-time tracking of its location and movement. This information can be used to monitor the usage patterns of the excavator, which can then be correlated with the performance data collected by the sensors. This comprehensive approach to tracking and monitoring enables operators to develop more accurate maintenance schedules, ensuring that the excavator remains in optimal condition at all times.

In addition to sensors and GPS technology, advanced software solutions are also being employed to track and monitor excavator parts. These software solutions integrate data from various sources, such as sensors, GPS devices, and operator inputs, to provide a holistic view of the excavator’s performance and maintenance requirements. This data-driven approach enables operators to make informed decisions about when and how to perform maintenance, ultimately reducing downtime and increasing the lifespan of the excavator.

Moreover, the use of augmented reality (AR) technology is gaining traction in the excavator maintenance sector. AR technology overlays digital information onto the real-world environment, providing operators with valuable insights into the performance and maintenance requirements of the excavator. This technology can be used to guide operators through complex maintenance procedures, ensuring that the excavator is maintained correctly and efficiently.

Lastly, predictive analytics is another advanced technology being used to track and monitor excavator parts for maintenance schedules. Predictive analytics involves the use of machine learning algorithms to analyze historical data and identify patterns that can be used to predict future maintenance requirements. This proactive approach to maintenance enables operators to address potential issues before they become major problems, thereby enhancing the overall efficiency and productivity of the excavator.

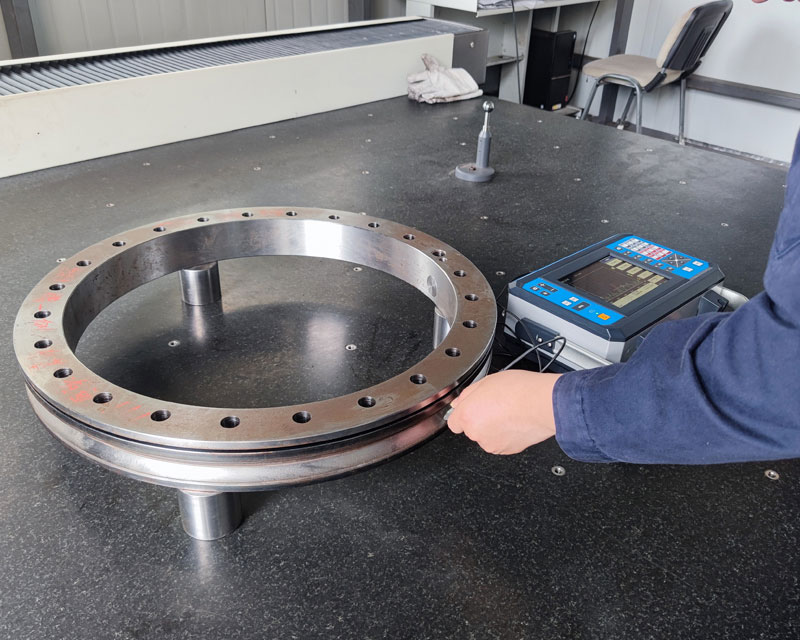

Riduttore di oscillazione

In conclusion, the integration of advanced technologies such as sensors, IoT, GPS, software solutions, AR, and predictive analytics has revolutionized the way excavator parts are tracked and monitored for maintenance schedules. These innovative methods enable operators to develop more accurate and proactive maintenance schedules, ultimately reducing downtime and increasing the lifespan of the excavator. As technology continues to advance, it is expected that these methods will become even more sophisticated, further transforming the construction industry and the way excavators are maintained.

Excavator parts are tracked and monitored for maintenance schedules through a combination of methods, including the use of sensors, software, and data analysis. Sensors are installed on various parts of the excavator to monitor their performance and detect any anomalies. This data is then transmitted to a central system, where it is analyzed to identify patterns and trends. Based on this analysis, maintenance schedules are created to ensure that the excavator parts are serviced and replaced as needed. Additionally, some excavator manufacturers offer remote monitoring services, which allow them to track the performance of their machines and provide maintenance recommendations. Overall, the tracking and monitoring of excavator parts for maintenance schedules help to improve the efficiency, safety, and longevity of the machines.