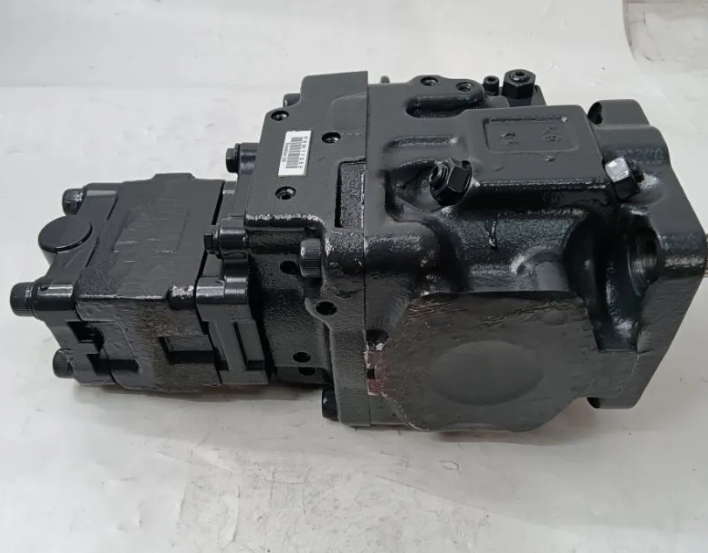

Hydraulic main pumps play a critical role in various industrial applications, serving as the primary source of power for hydraulic systems in heavy machinery. These pumps are responsible for converting mechanical power into hydraulic energy, which is used to control the movement of hydraulic cylinders, motors, and other components in equipment such as excavators, loaders, and bulldozers.

Seal and Gasket Replacement for Hydraulic Main Pumps:

Proactively replacing worn or damaged seals, gaskets, and O-rings in Hydraulic Main Pumps is crucial to prevent fluid leaks, maintain hydraulic system integrity, and ensure reliable pump performance. Hydraulic Main Pumps play a vital role in various industrial applications, and proper maintenance of their sealing components is essential for optimal operation.

To begin the replacement process for Hydraulic Main Pumps, first, identify the location of the seals, gaskets, or O-rings within the pump assembly that require replacement. These components are typically found in areas where fluid flow is present, such as pump connections, fittings, and valve assemblies.

Carefully remove the old seals, gaskets, or O-rings from the Hydraulic Main Pump using appropriate tools to avoid damaging surrounding components. Inspect the sealing surfaces within the pump for any signs of wear, corrosion, or damage that may have contributed to the failure of the original components. Thoroughly clean the sealing surfaces to ensure proper adhesion and sealing of the new components.

Select replacement seals, gaskets, or O-rings that are specifically designed for Hydraulic Main Pumps and meet the manufacturer’s specifications for compatibility and performance. Apply a thin layer of compatible lubricant to the new components to facilitate installation and ensure proper sealing. Install the new seals, gaskets, or O-rings securely in their designated locations, following the recommended torque specifications provided by the pump manufacturer.

After replacing the seals, gaskets, or O-rings in the Hydraulic Main Pump, conduct a thorough inspection to verify proper installation and sealing effectiveness. Test the pump for leaks and monitor for any signs of fluid seepage around the replaced components. Regularly monitor the replaced seals and gaskets during routine maintenance to ensure continued integrity and prevent potential leaks that could compromise the performance of the Hydraulic Main Pump.

By proactively replacing worn or damaged seals, gaskets, and O-rings in Hydraulic Main Pumps, operators can prevent fluid leaks, maintain the integrity of the hydraulic system, and sustain reliable pump performance over time.

Fluid Flush and Filter Change for Hydraulic Main Pumps:

Implementing regular fluid flushes, filter replacements, and hydraulic system cleaning procedures is essential for Hydraulic Main Pumps to remove contaminants, extend component life, and optimize hydraulic fluid quality. Proper maintenance of the hydraulic fluid and filtration system is critical for the efficient operation of Hydraulic Main Pumps in industrial settings.

To begin the fluid flush process for Hydraulic Main Pumps, first, identify the type of hydraulic fluid used in the system and ensure compatibility with the replacement fluid. Proper fluid selection is crucial for maintaining the performance and longevity of Hydraulic Main Pumps. Shut down the Hydraulic Main Pump system and allow it to cool before draining the existing fluid from the reservoir.

Use a suitable container to collect the old fluid from the Hydraulic Main Pump and dispose of it according to environmental regulations. After draining the old fluid, flush the system with the recommended flushing solution to remove any residual contaminants, debris, or sludge that may have accumulated in the pump.

Next, replace the hydraulic filters in the Hydraulic Main Pump with new, clean filters to ensure efficient filtration of the fluid and removal of contaminants. Select filters that meet the pump system’s specifications and flow requirements to maintain optimal performance. Install the new filters securely in their designated locations, following the manufacturer’s instructions for proper installation.

Refill the hydraulic system of the Hydraulic Main Pump with the appropriate type and quantity of fresh hydraulic fluid that meets the manufacturer’s specifications for viscosity and performance. Bleed air from the system as needed to ensure proper fluid circulation and eliminate air pockets that can affect the operation of Hydraulic Main Pumps.

By implementing regular fluid flushes, filter replacements, and hydraulic system cleaning procedures for Hydraulic Main Pumps, operators can remove contaminants, extend component life, and optimize the quality of hydraulic fluid to maintain system efficiency and reliability.

Pump Rebuild or Replacement for Hydraulic Main Pumps:

Considering rebuilding or replacing the hydraulic pump in Hydraulic Main Pumps is necessary when internal components show signs of wear, scoring, or damage to restore optimal performance, efficiency, and reliability. Hydraulic Main Pumps are critical components in hydraulic systems, and maintaining their functionality is essential for sustained operation.

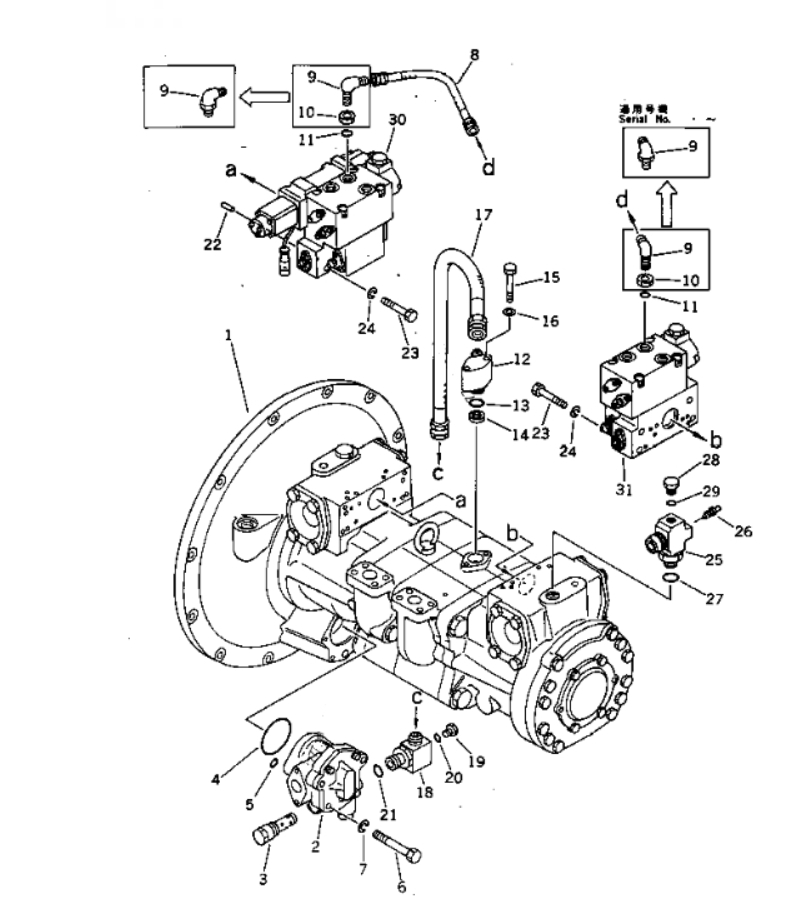

To begin the pump rebuild process for Hydraulic Main Pumps, first, safely shut down the system and relieve any pressure in the hydraulic system. Remove the pump from its mounting location within the Hydraulic Main Pump assembly and disassemble it according to the manufacturer’s guidelines and technical specifications. Inspect internal components such as pistons, cylinders, valves, and bearings for wear, scoring, or damage that may be affecting pump performance.

Replace worn or damaged components within the Hydraulic Main Pump with genuine replacement parts that meet the manufacturer’s specifications for compatibility and performance. Carefully reassemble the pump, ensuring proper alignment and torque of fasteners to prevent leaks or malfunctions. Test the rebuilt pump for proper operation and monitor for any abnormalities or unusual noise during system operation.

If the damage to the hydraulic pump in the Hydraulic Main Pump is extensive and a rebuild is not feasible, pump replacement may be necessary to ensure continued system operation. Select a replacement pump that matches the Hydraulic Main Pump system requirements, flow rates, and pressure ratings to ensure compatibility and seamless integration with the hydraulic system.

After rebuilding or replacing the hydraulic pump in Hydraulic Main Pumps, conduct thorough testing and monitoring to verify proper operation and performance. Regularly inspect the pump during routine maintenance to identify any signs of wear or damage early and address them promptly to prevent system failures and maintain the optimal performance of Hydraulic Main Pumps.

By considering pump rebuild or replacement when internal components show signs of wear or damage in Hydraulic Main Pumps, operators can restore optimal performance, efficiency, and reliability to the hydraulic system.

Cooling System Inspection for Hydraulic Main Pumps:

Inspecting and maintaining the cooling components of Hydraulic Main Pumps, including radiators, fans, cooling lines, and temperature sensors, is essential to prevent overheating, ensure proper heat dissipation, and prolong the life of the pump. Proper cooling system operation is critical for maintaining the optimal operating temperature of Hydraulic Main Pumps and preventing thermal damage.

To begin the cooling system inspection for Hydraulic Main Pumps, visually inspect the radiator, fins, and cooling lines for any signs of damage, corrosion, or blockages that may impede heat dissipation. Clean the radiator fins and cooling components using compressed air or a soft brush to remove dirt, debris, or obstructions that can hinder airflow and cooling efficiency.

Check the condition of the cooling fan and motor in the Hydraulic Main Pump system to ensure proper operation and airflow through the cooling system. Test the fan motor for functionality and monitor for any unusual noise or vibrations that may indicate issues with the fan assembly. Replace damaged or malfunctioning fan components as needed to maintain efficient cooling performance.

Inspect the temperature sensors and gauges within the Hydraulic Main Pump system to verify accurate temperature readings and ensure the system is operating within the recommended temperature range. Calibrate or replace faulty sensors to prevent inaccurate temperature monitoring and potential overheating issues that could impact the performance of Hydraulic Main Pumps.

Regularly monitor the cooling system of Hydraulic Main Pumps during routine maintenance to detect any abnormalities or signs of overheating early. Maintain proper airflow around the cooling components by keeping surrounding areas clear of obstructions and ensuring adequate ventilation for optimal heat dissipation and cooling performance.

By conducting regular inspections and maintenance of the cooling components of Hydraulic Main Pumps, operators can prevent overheating, ensure proper heat dissipation, and prolong the life of the pump and associated hydraulic system components.

Professional Consultation for Hydraulic Main Pumps:

Seeking expert advice and consultation from certified hydraulic technicians, engineers, or service providers is essential for diagnosing complex pump issues, implementing effective repair solutions, and enhancing overall hydraulic system performance and longevity of Hydraulic Main Pumps. Professional consultation provides access to specialized knowledge and resources necessary to address challenging pump problems and optimize system operation.

When encountering complex pump issues or challenges beyond your expertise with Hydraulic Main Pumps, consult certified hydraulic technicians or engineers for a thorough evaluation of the system. Provide detailed information about the symptoms, performance issues, and maintenance history of the pump to facilitate an accurate diagnosis and effective repair plan.

Collaborate with experienced service providers to conduct diagnostic tests, inspections, and performance evaluations of Hydraulic Main Pumps to identify underlying issues and potential root causes affecting pump performance. Utilize advanced diagnostic tools and techniques to analyze system operation, flow rates, pressure levels, and component functionality for a comprehensive assessment.

Work closely with hydraulic experts to develop tailored repair solutions, maintenance strategies, and performance enhancement recommendations based on the specific needs and requirements of Hydraulic Main Pumps. Implement expert advice and best practices to optimize pump performance, prevent failures, and extend the lifespan of the hydraulic equipment in the system.

Regularly engage in professional consultation and collaboration with certified hydraulic technicians, engineers, or service providers to stay informed about the latest industry developments, technologies, and maintenance practices for Hydraulic Main Pumps. Continuously seek opportunities to enhance your knowledge, skills, and expertise in hydraulic system maintenance and troubleshooting to ensure optimal performance and reliability of Hydraulic Main Pumps.

By seeking expert advice and consultation from qualified professionals for Hydraulic Main Pumps, operators can diagnose complex pump issues, implement effective repair solutions, and enhance overall hydraulic system performance and longevity. Collaborating with experienced technicians and engineers provides valuable insights, recommendations, and solutions to optimize Pump Main Pumps operation and ensure system reliability.

In conclusion, troubleshooting common issues with hydraulic main pumps requires a systematic and proactive approach, encompassing thorough inspection, accurate diagnosis, and appropriate repair and maintenance strategies. By understanding the symptoms, diagnostic procedures, and repair techniques outlined in this comprehensive guide, equipment operators, maintenance personnel, and hydraulic system users can effectively address hydraulic pump problems, optimize system performance, and ensure the reliable operation of industrial machinery for enhanced productivity and safety.

Question 1: What are the common causes of failure in Main Pumps?

Answer: The common causes of failure in Main Pumps can include wear and tear of internal components, contamination of hydraulic fluid, inadequate maintenance, improper installation, and overheating due to insufficient cooling. Regular inspection, proper maintenance, and timely replacement of worn parts can help prevent pump failures.

Question 2: How can operators optimize the performance of Main Pumps?

Answer: Operators can optimize the performance of Main Pumps by conducting regular maintenance, including fluid flushes, filter changes, and seal replacements. Monitoring pump operation for any abnormal noise, leaks, or performance issues can help identify potential problems early. Proper installation, correct fluid selection, and ensuring adequate cooling are also essential for optimizing pump performance.

Question 3: What are the benefits of professional consultation for Main Pumps maintenance?

Answer: Professional consultation for Main Pumps maintenance provides access to specialized knowledge, expertise, and diagnostic tools that can help identify complex pump issues, develop effective repair solutions, and optimize system performance. Collaborating with certified hydraulic technicians or engineers can enhance the longevity, efficiency, and reliability of Main Pumps in industrial applications.