In the realm of rotating machinery, the lingkaran ayun, also known as a slewing bearing or turntable bearing, stands as a remarkable engineering marvel. Operating behind the scenes, this unassuming yet crucial component enables smooth rotation while bearing substantial loads and moments. Slewing bearings are essential in a myriad of applications, from heavy-duty industrial machinery to sophisticated telescopes. Despite their critical role, they often go unnoticed. In this blog, our slew ring bearing manufacturers will take a deep dive into the mechanics of how a Swing circle works, exploring the principles that underpin its operation and the factors that make it a key player in various industries.

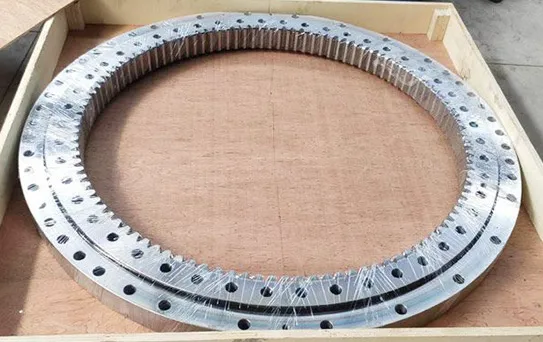

A swing circle bearing, commonly referred to as a slewing bearing or turntable bearing, is a specialized rolling-element bearing designed to handle axial, radial, and moment loads, all while enabling smooth rotation around a fixed axis. To fully appreciate its inner workings, it is crucial to understand its key components and their functions.

The Swing circle bearing features two sets of precisely machined circular raceways: the inner and outer raceways. These raceways form the main circular tracks on which the rotating and stationary elements of the bearing interface. The precision in the machining of these raceways is vital as it directly affects the performance and durability of the bearing. The smoothness and hardness of the raceway surfaces are crucial to minimize wear and ensure the bearing can support heavy loads without deforming.

The critical elements responsible for facilitating rotation are the rolling elements, which are positioned between the two raceways. These rolling elements can vary in type, with common options including balls, cylindrical rollers, and tapered rollers. The choice of rolling element depends on the specific application and the types of loads the bearing will encounter. For instance, ball bearings are typically used for applications requiring lower friction and higher speed, while cylindrical and tapered rollers are better suited for applications involving heavier loads.

The rolling elements are kept evenly spaced and positioned through a cage, which prevents friction between the rolling elements and ensures uniform load distribution during rotation. The cage is typically made of durable materials such as steel or brass and is designed to withstand the forces exerted during operation. By maintaining the proper spacing and alignment of the rolling elements, the cage helps reduce wear and tear, prolonging the bearing’s lifespan.

Swing bearings are equipped with seals to protect the internal components from contaminants such as dust, water, and other debris. These seals are crucial for maintaining the integrity of the bearing’s internal environment, ensuring that the rolling elements and raceways remain clean and free from abrasive particles. Proper lubrication is also essential to reduce friction and wear between moving parts. Lubricants, such as grease or oil, form a thin film on the surfaces of the rolling elements and raceways, minimizing direct metal-to-metal contact and thus reducing friction and heat generation.

Understanding the operation of a Swing circle bearing involves delving into the mechanics of load distribution, friction minimization, and support for axial and radial loads. Each of these aspects plays a vital role in the bearing’s overall performance and efficiency.

When a load is applied to a rotating structure mounted on a Swing circle, the force is transferred through the bearing’s raceways and distributed to the rolling elements. The rolling elements, in turn, transmit the load to the stationary raceway and the structure’s mounting point. This load distribution mechanism allows the Swing circle to support heavy loads with ease. The ability to evenly distribute loads across multiple rolling elements ensures that no single element bears an excessive amount of stress, which would otherwise lead to premature wear or failure.

For instance, in a crane, the weight of the load being lifted is transferred through the slewing bearing to the crane’s base. The bearing’s design allows it to handle both the vertical load from the weight and the horizontal forces resulting from the crane’s rotation. This balanced load distribution is crucial for maintaining the crane’s stability and preventing structural damage.

The rolling elements play a pivotal role in enabling rotation. As the inner raceway rotates relative to the outer raceway, the rolling elements smoothly move between the two tracks, minimizing friction and allowing for smooth, low-resistance rotation. This low friction is essential for the efficient operation of machinery, as it reduces the energy required to initiate and maintain rotation.

In applications like wind turbines, where the slewing bearing allows the rotor to adjust its orientation to capture the wind, minimal friction is vital for maintaining high efficiency. The reduced friction also means less wear on the rolling elements and raceways, contributing to a longer operational life for the bearing.

Swing circles are designed to handle both axial and radial loads, making them versatile components suitable for a wide range of applications. The ability to support axial loads ensures stability during lateral movements, while radial support enables the bearing to withstand vertical loads. This dual capability is crucial for applications where the bearing must support complex load patterns.

For example, in an excavator, the slewing bearing supports the weight of the arm and bucket (radial load) while also allowing for the rotation of the upper structure (axial load). This dual support ensures the excavator can perform its digging and lifting tasks efficiently and reliably.

The Swing circle, often overshadowed by other mechanical components, plays a crucial role in the smooth operation of rotating machinery across numerous industries. Its ingenious design, encompassing raceways, rolling elements, and a cage, ensures seamless rotation and the ability to bear immense loads with stability and precision. Whether in cranes, excavators, wind turbines, or telescopes, the Swing circle silently facilitates movement and enables the wonders of modern engineering. Understanding the mechanics behind this unassuming bearing reinforces its significance and appreciation as a fundamental building block of rotating machinery.

Q1: What are the main components of a Swing circle bearing?

A1: The main components of a Swing circle bearing include the inner and outer raceways, rolling elements (such as balls, cylindrical rollers, or tapered rollers), a cage to keep the rolling elements evenly spaced, and seals to protect against contaminants. Proper lubrication is also essential to reduce friction and wear.

Q2: How does a Swing circle bearing distribute loads?

A2: When a load is applied to a rotating structure mounted on a Swing circle, the force is transferred through the bearing’s raceways and distributed to the rolling elements. These elements then transmit the load to the stationary raceway and the structure’s mounting point, ensuring that the bearing can support heavy loads with ease.

Q3: Why is minimal friction important in the operation of a Swing circle bearing?

A3: Minimal friction is important because it reduces the energy required to initiate and maintain rotation, leading to more efficient operation of machinery. It also reduces wear on the rolling elements and raceways, contributing to a longer operational life for the bearing.

Q4: What types of loads can a Swing circle bearing support?

A4: A Swing circle bearing can support both axial and radial loads. Axial loads are forces applied parallel to the axis of rotation, while radial loads are forces applied perpendicular to the axis of rotation. This dual capability makes Swing circle bearings suitable for applications requiring support for complex load patterns.

Q5: How do seals and lubrication contribute to the performance of a Swing circle bearing?

A5: Seals protect the internal components of the bearing from contaminants such as dust, water, and debris, maintaining the integrity of the internal environment. Proper lubrication reduces friction and wear between moving parts by forming a thin film on the surfaces of the rolling elements and raceways, minimizing direct metal-to-metal contact. This ensures smooth operation and prolongs the bearing’s lifespan.

Q6: In which industries are Swing circle bearings commonly used?

A6: Swing circle bearings are commonly used in industries such as construction (cranes and excavators), renewable energy (wind turbines), and precision instruments (telescopes). Their ability to support heavy loads and facilitate smooth rotation makes them indispensable in these and other applications.

By delving into the mechanics of how a Swing circle bearing works and understanding its components and functions, we can appreciate the critical role it plays in various engineering applications. This knowledge not only highlights the bearing’s importance but also underscores the need for proper maintenance and care to ensure its optimal performance and longevity.