A lengőcsapágyak (forgócsapágyak) a mechanikai alkatrészek új típusa. Belső gyűrűből, külső gyűrűből, gördülőelemből stb. áll. a lengőcsapágyak nagyméretű csapágyak, amelyek képesek a teljes terhelést elviselni. Egyszerre képes nagy axiális terhelések, radiális terhelések és billenőnyomatékok felvételére. Kompakt szerkezettel, kis tömeggel, kiváló szerkezeti merevséggel, nagy pontossággal, biztonsággal és megbízhatósággal rendelkezik.

Ma összehasonlítjuk a lengőcsapágyak és a siklócsapágyak közötti hasonlóságokat és különbségeket. Mindkettő ugyanazzal a működési elvvel, szerkezettel és alkatrészekkel rendelkezik. Mindkettő gördülő kerék gördülőelemekkel és pályákkal rendelkezik. A hagyományos csapágyakhoz képest azonban számos különbség van.

Bearings are essential components in machinery, enabling smooth and efficient movement between parts. Among the various types of bearings, swing bearings and plain bearings stand out due to their unique characteristics and applications. Understanding the differences between these two types of bearings can help in selecting the right bearing for specific mechanical systems. This article delves into the key differences between swing bearings and plain bearings, covering aspects such as installation methods, size, structure, load capacity, operating speed, manufacturing process, and sealing devices.

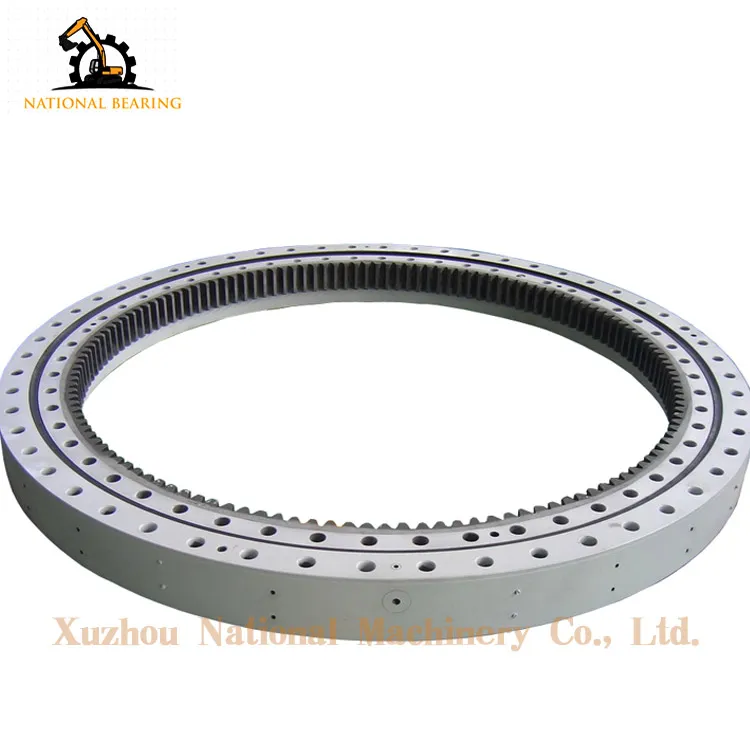

Swing bearings, also known as slewing bearings, are not attached to a spindle like regular bearings. Instead, they are mounted onto a bearing housing. The installation of swing bearings involves attaching them to the top and bottom supports using screws or bolts. This unique installation method allows swing bearings to support large and complex structures such as cranes, excavators, and wind turbines.

Plain bearings, also known as bushings, are generally simpler in design and installation compared to swing bearings. They are typically mounted directly onto the spindle or shaft, allowing for a straightforward and compact setup.

Swing bearings are characterized by their large size, which can range from 0.4 meters to 10 meters in diameter. In some specialized applications, the diameter of swing bearings can reach up to 40 meters. This substantial size enables them to support heavy and large structures.

Plain bearings are generally much smaller in size compared to swing bearings. Their compact dimensions make them suitable for applications where space is limited and the loads are relatively lighter.

Swing bearings are available in a variety of designs, each tailored to specific applications and load requirements. They can be broadly classified into two main types based on the contact mechanism: point contact and line contact.

Plain bearings have a simpler structure compared to swing bearings. They can be classified based on their material and design into several types, such as sleeve bearings, flanged bearings, and thrust bearings.

Swing bearings are designed to withstand a variety of lateral loads, including axial and radial forces as well as large tilting moments. This ability to handle multiple load types simultaneously makes them suitable for heavy-duty applications.

Plain bearings, on the other hand, are generally designed to handle lower loads compared to swing bearings. Their load capacity is usually limited to lighter applications where the forces are not as intense.

The operating speed of swing bearings is typically very low, usually less than 10 revolutions per minute (rpm). Additionally, swing bearings often do not rotate continuously but rather operate within a specific angle, corresponding to the so-called “swing arm bearing.”

Plain bearings can operate at much higher speeds compared to swing bearings. Their simple design allows them to handle continuous and high-speed rotation efficiently.

The manufacturing process for swing bearing is complex and involves high precision and advanced techniques. The materials and workmanship required for swing bearings are specialized to ensure durability and reliability under heavy loads.

Plain bearings have a simpler manufacturing process compared to swing bearings. They are made from various materials, including metals, polymers, and composites, depending on the application requirements.

Swing bearings are usually equipped with teeth for rotational drive and seals to keep out dust and contaminants. These sealing devices are essential for maintaining the cleanliness and longevity of the bearing.

Plain bearings may also incorporate sealing devices, but they are generally simpler compared to those used in swing bearings. The seals in plain bearings are designed to keep lubrication in place and prevent contaminants from entering.

In summary, swing bearings and plain bearings differ significantly in various aspects, including installation methods, size, structure, load capacity, operating speed, manufacturing process, and sealing devices. Swing bearings are designed for heavy-duty applications requiring large size, high load capacity, and low-speed rotation. They are complex in design and manufacturing, with advanced sealing mechanisms to ensure durability and reliability.

On the other hand, plain bearings are simpler and smaller, suitable for high-speed, low-load applications. Their straightforward design and manufacturing process make them cost-effective and easy to produce. Understanding these differences can help in selecting the right bearing for specific mechanical systems, ensuring optimal performance and longevity.

1. Könnyen feldolgozható, érzékeny, alacsony forgási ellenállás.

2. Kompakt szerkezet, kis külső méretekkel (főleg magasság).

3. Könnyű karbantartás és hosszú élettartam.

4. Lánckerekekből, tömítésekből, csavarokból stb. áll, könnyen telepíthető és professzionális termelési központosítás.

5. Nincs köztes forgáspont, a résbe más alkatrészek is beépíthetők.

Do you understand the difference between swing bearings and plain bearings? NATIONAL slewing bearings are used in a variety of applications, mainly in lifting machinery (truck cranes, tower cranes, etc. ), construction machinery (excavators, loaders, etc. ), transportation machinery, etc. Of course, the same applies to kotrógép lengőcsapágy. Többféle modellt kínálunk, hogy tökéletesen illeszkedjen az Ön gépéhez.

| modell | Cikkszám | modell | Cikkszám | modell | Cikkszám | modell | Cikkszám | modell | Cikkszám | modell | Cikkszám |

| CAT 307 | 102-6377 | CAT 325C | 227-6087 | PC15 | 20M-25-81201 | PC240-8 | 206-25-00301 | EX60-2 | 4193433 | ZX230 | 9154037 |

| CAT 307C | 240-8361 | CAT 325 | 199-4483 | PC18 | 20M-25-81201 | PC270 | 206-25-00400 | EX60WD -2 | 4193433 | ZX230 | 9159646 |

| CAT 308C | 240-8362 | CAT 325 | 4178151 | PC75UU-2 | 201-25-61100 | PC290 | 206-25-00400 | EX60-5 | 43767553 | ZX240 | 9196732 |

| CAT 312CL | 229-1077 | CAT 325 | 3530676 | PC100-6 | 203-25-62100 | PC300 | 207-25-31112 | EX100 | 9098995 | ZX240 | 9245728 |

| CAT 311 | 231-6853 | CAT 325 | 2316854 | PC110R | 206-25-11100 | PC300-3 | 207-25-00022 | EX100-3 | 9102726 | EX300-3 | 9112188 |

| CAT 312B | 616411 | CAT 325CL | 199-4475 | PC120-5 | 203-25-51200 | PC300-6 | 207-25-61100 | ZX135 | 9184497 | ZX330LC-5G | 9245698 |

| CAT 312CL | 229-1077 | CAT 326 | 353-0649 | PC120-6Z | 203-25-61100 | PC300-7 | 207-25-61100 | EX150-5 | 9146953 | ZX350-3 | 9245698 |

| CAT 312C | 229-1077 | CAT 329D | 227-6087 | PC120-6 | 203-25-62100 | PC300-7 | 207-25-61700 | EX200 | 9098993 | ZX370 | 9166468 |

| CAT 315 | 148-4568 | CAT 330 | 7Y0933 | PC130-6 | 203-25-62100 | PC300LC-5 | 207-25-51100 | ZX200LC-5G | 9260971 | ZX370 | 9169894 |

| CAT 318B | 148-4568 | CAT 330 | 1994559 | PC130-7 | SAA4D95L | PC300LC-6 | 207-25-61100 | ZX200-3, | 9260971 | KH180-3 | 9099074 |

| CAT M315 M318 | 145-4809 | CAT 330 | 353-0487 | PC150LCK-6 | 21P-25-K1100 | PC300LC-7 | 207-25-61100 | EX200-3 | 9148123 | HE6010B | 1214DBS110T |

| CAT 315C | 229-1080 | CAT 330B | 231-6859 | PC160-6K | 21P-25-K1100 | PC300-8 | 207-25-61100 | ZX200 | 9196732 | EX400 | 164-2568 |

| CAT 319C | 227-6079 | CAT 330B | 114-1434 | PC160-7 | 21K-25-00101 | PC300-8 | 207-25-00121 | ZX200-5G | 9260971 | EX400-5 | 9129521 |

| CAT320B | 1141414 | CAT 330D | 227-6089 | PC200 | 205-25-00015 | PC340 | 207-25-61200 | EX200 | 9102727 | ZX450 | 9129521 |

| CAT320BL | 121-8222 | CAT 330C | 227-6089 | PC210NlC-7K | 20Y-25-00301 | PC380LC-6K | 207-25-61200 | EX210-5 | 9102727 | ZX450-3 | 9247287 |

| CAT 320 | 7Y1565 | CAT330D/DL | 227-6090 | PC200-5 | 20Y-25-11103 | PC400-7 | 208-25-61100 | ZX210LCK | 9169646 | ZX450-3 | 9247287 |

| CAT 320B | 114-1505 | CAT 336D | 353-0489 | PC200-8 | 206-25-00200 | PC400LC-5 | 208-25-52101 | ZX210W-1 | 9275368 | ZX470-3 | 9247287 |

| CAT 320BL | 177-7723 | CAT 336DL | 227-6089 | PC200-6 | 20Y-25-20200 | PC400LC-5 | 208-25-52100 | ZX220 | 9262248 | ZX650 | 9321213 |

| CAT 320BL | 114-1341 | CAT 336DL | 353-0680 | PC200-6Z | 20Y-25-22200 | PC400LC-5 | 208-25-52101 | EX220-1 | 9154037 | ZX650LCH | 6016584 |

| CAT 320C | 227-6081 | CAT 336D | 353-0490 | PC200-6 | S6D102-1 | PC400LC-5 | 208-25-A2100 | ZX225USR | 9169646 | ZX800LD | 9229741 |

| CAT 320C | 227-6147 | CAT 345 | 227-6052 | PC200-7 | 20Y-25-21200 | PC400LC-6 | 208-25-61100 | ZX225US | 9196732 | ZX870-3 | 9321216 |

| CAT 320C | 171-9425 | CAT 345B | 136-2969 | PC220-7 | 120Y-25-21300 | PC400 | 208-25-61100 | ZX330-3LC | 9260971 | ZX870 | 6023643 |

| CAT 320D | 227-6082 | CAT 345B | 200-3645 | PC200LC-7 | 20Y-25-21200 | PC450LC-6K | 208-25-61100 | EX270-5 | 9154037 | ||

| CAT 320L | 7Y1563 | CAT 345BII | 227-6094 | PC220 | 205-25-00022 | PC450-8 | 208-25-71230 | R110-7 | 81N3-01022 BG | R250/260 | 81EN-00051 |

| CAT 320L | 7Y1563 | CAT 345BL | 136-2970 | PC220LC-6LE | 20Y-25-A1101 | PC450-8 | 207-25-31180 | R140LC-7 | 81N4-01020 | R250LC-7 | 8 |

| CAT 225 | 8K4127 | CAT 345BL | 169-5536/169-5537 | PC220-6 | 20Y-25-21200 | PC450-8 | 208-25-61100 | R160LC-7 | 81EM-00020 | 290LC-7 | 81N8-0003 |

| CAT 322C | 221-6764 | CAT 345DL | 227-6037 | PC220-6 | 20Y-25-21100 | PC600-7 | 21M-25-11100 | R160LC-7 | 81EM-00021 | R290/300 | 81N8-00021 |

| CAT 324D | 227-6085 | CAT 345ECL | 227-6052 | PC220-7 | 206-25-00301 | pc600-7 | 21M-25-11102 | R170W-7 | 81EM-00021 | R290 | 81N8-00022 |

| CAT 325 | 7Y0745 | CAT 349D | 353-0490 | PC220-8 | 206-25-00320 | PC600LC-6 | 21M-25-11100 | R180W-9S | 81EM-00021GG | R290LC 7A | 4921797 |

| CAT 350 | 1026392 | CAT374 | 333-3009 | PC220LC-8 | 206-25-00301 | PC600LC-8 | 21M-25-11101 | R200W-7 | 81EM-00021GG | R290LC-7 | 81N8-00023 |

| CAT 365C | 199-4565 | CAT374 | 367-8361 | PC228US-3 | 22U-25-00201 | PC750 | 209-25-71100 | R210-7 | 81N6-00023BG | R290LC-7A | 81N8-00024GG |

| CAT 365C | 227-6096 | CAT 385C | 199-4491 | PC228 | 22U-25-00210 | PC800LC-8 | 209-25-00102 | R210LC-7 | 81N6-01020 | R320/330 | 81N9-01020 |

| CAT 365C | 227-6097 | CAT 385C | 227-6099 | PC228 | 22U-25-00220 | PC800-6 | 209-25-00101 | R210-7 | 81N6-00022 | R320LC-7 | 81N9-01021 |