When it comes to the functionality and efficiency of heavy machinery such as excavators, every component plays a crucial role. One of the most critical components in an excavator is the swing bearing. In this comprehensive blog, we will delve into the specifics of the Caterpillar Excavator E140 swing bearing, discussing its significance, construction, maintenance, and why it is essential to choose the right swing bearing for your equipment.

Swing bearings are pivotal in the functionality of an excavator, facilitating the smooth rotation of the machine’s upper structure. This rotation is essential for maneuverability, allowing the excavator to swing from side to side, which is crucial for tasks such as digging, lifting, and placing materials. The swing bearing for the Caterpillar Excavator E140, identified by Part # 093-7013, is designed to meet the demanding needs of this model, ensuring optimal performance and durability.

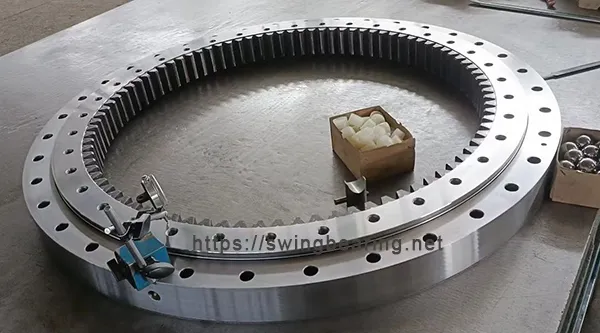

The Caterpillar Excavator E140 swing bearing, part numbers 093-7013 and 096-8063, is custom-designed to fit the E140 model seamlessly. This specific design ensures that the swing bearing integrates perfectly with the existing components of the excavator, restoring its swing function to like-new performance.

The swing bearing weighs 524 lbs, a testament to its robust construction. The weight and dimensions of the bearing are critical as they directly impact the performance and durability of the component. The substantial weight indicates a heavy-duty bearing capable of withstanding the rigorous demands of excavation work.

This swing bearing replaces part numbers 093-7013 and 096-8063, ensuring compatibility and ease of replacement. Using bearings specifically designed for the E140 model eliminates the risks associated with using generic parts, such as improper fitting and premature wear, which can lead to costly downtime and repairs.

The construction of the swing bearing involves high-grade materials designed to withstand extreme conditions. Typically, these bearings are made from hardened steel, providing excellent wear resistance and longevity. The precision engineering ensures that the bearing can handle both radial and axial loads efficiently.

The swing bearing undergoes rigorous heat treatment and hardening processes to enhance its strength and durability. These processes ensure that the bearing can withstand the heavy loads and repetitive movements typical of excavation work.

Seals and lubrication are crucial components of the swing bearing. High-quality seals prevent contaminants such as dirt and moisture from entering the bearing, while proper lubrication reduces friction and wear, ensuring smooth operation and extending the bearing’s lifespan.

Regular inspection and lubrication are essential for maintaining the performance and longevity of your swing bearings. Check for any signs of wear, corrosion, or damage. Ensure that the bearings are properly lubricated to reduce friction and wear.

Look for visible signs of wear, such as pitting, spalling, or discoloration. Listen for any unusual noises during operation, which could indicate internal damage. Early detection of wear can prevent more severe damage and costly repairs.

Use the recommended lubricant for your swing bearings. Apply the lubricant according to the manufacturer’s guidelines, ensuring even coverage. Regular lubrication helps reduce friction, wear, and the risk of bearing failure.

Keeping the swing bearing clean and free of contaminants is crucial. Regularly clean the bearing and surrounding areas to remove dirt and debris that can cause damage. Protect the bearing from harsh environmental conditions to prevent corrosion and wear.

Proper preparation is crucial for a successful installation. Ensure that the work area is clean and free of contaminants. Gather all necessary tools and equipment before starting the installation process.

After installation, perform a thorough inspection to ensure that the bearing is properly secured and functioning correctly. Check for any signs of misalignment or binding. Regular post-installation checks can help prevent future issues and extend the bearing’s lifespan.

Our swing bearings are specifically designed for the Caterpillar E140 excavator. This means they are a perfect fit, ensuring optimal performance and longevity. Using bearings that are tailored for your specific model eliminates the risks associated with using generic parts, such as improper fitting or premature wear.

Built to withstand the demanding conditions of excavation work, our swing bearings offer both durability and reliability. The use of high-quality materials and rigorous testing ensures that these bearings can handle the pressures and stresses of daily operation.

Our freight shipping process ensures that your swing bearings are delivered securely and on time, minimizing downtime and keeping your operations running smoothly. Each bearing is carefully packaged to protect it from impacts and vibrations during transit.

Swing bearings are critical components in the operation of Caterpillar Excavators, particularly the E140 model. The Part # 093-7013 swing bearing, tailored specifically for this excavator, offers durability, reliability, and optimal performance. Ensuring proper maintenance, timely inspection, and correct installation are key to maximizing the lifespan and efficiency of these bearings. By choosing high-quality, compatible parts and following best practices for care, you can keep your excavator running smoothly and efficiently.

A : Signs that your swing bearing may need replacement include unusual noises during operation, visible wear or damage, increased friction, and difficulty in rotating the excavator’s upper structure. Regular inspections can help detect these signs early.

A : Regular inspections should be conducted daily, with thorough checks at least once a month. Lubrication should be done according to the manufacturer’s recommendations, typically every 100-200 hours of operation, or more frequently in harsh conditions.

A : While it is possible to install the swing bearing yourself if you have the necessary tools and expertise, it is often recommended to hire a professional. Proper installation is crucial for ensuring the bearing’s performance and longevity, and a professional can ensure it is done correctly.

A : Use a high-quality lubricant that meets the manufacturer’s specifications for your swing bearing. Typically, this will be a heavy-duty grease designed for high-load, high-speed applications. Consult your equipment’s manual for specific recommendations.

A : The weight of the swing bearing, such as the 524 lbs for the Caterpillar E140, indicates its robustness and ability to handle the stresses of excavation work. A heavier bearing typically offers greater durability and reliability, ensuring long-lasting performance under heavy loads.