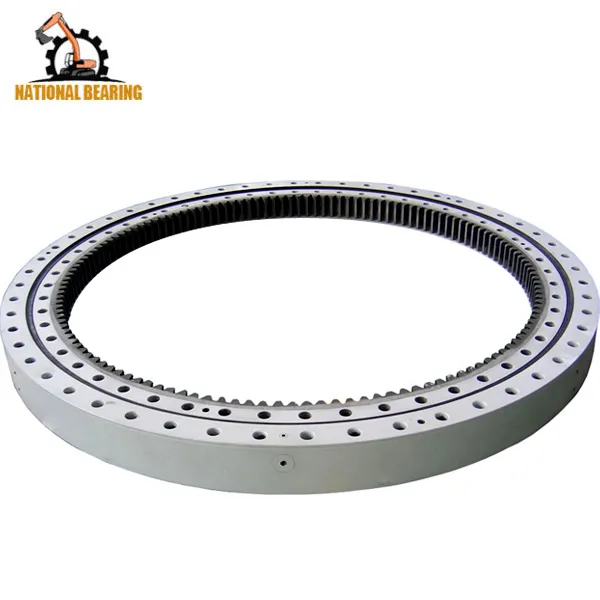

Excavators are indispensable in the construction and mining industries, and one of their most critical components is the swing bearing. The swing bearing, particularly the Laagrid 227-6037 CAT 345DL jaoks 227-6037, supports the upper structure’s weight and enables its rotation. A failure in this component can lead to significant damage and pose dangers to the operator. Hence, regular maintenance and repair of the swing bearing are crucial to avoid costly downtime and potential accidents. This blog will explore common challenges in maintaining and repairing swing bearings and provide solutions to these issues.

Before addressing the challenges and solutions, it is important to emphasize the significance of proper maintenance for swing bearings. Regular inspection and lubrication can significantly extend the bearing’s lifespan and prevent severe damage. Most excavator manufacturers recommend inspecting the swing bearing every 500 hours of operation and lubricating it at least every 250 hours. Neglecting these guidelines can lead to expensive repairs or even the need for a complete replacement of the swing bearing. Therefore, adhering to a proper maintenance schedule is essential to avoid unnecessary expenses and operational downtime.

Dust and dirt build-up in the swing bearing can cause severe damage to its internal components. When dust mixes with lubrication oil, it forms a gritty paste that can quickly wear down bearing surfaces. The abrasive particles can lead to scoring, pitting, and other forms of damage to the raceways.

Lahendus: Regular cleaning of the bearing housing and replacing the lubrication oil is key. High-pressure air or steam cleaning can effectively remove dirt and debris from the housing. Additionally, incorporating seals or covers can reduce the amount of dust and dirt that accumulates inside the bearing.

Misalignment of the swing bearing can result from improper installation, wear of the bearing surfaces, or external stress on the machine. Misalignment causes uneven wear of the bearing surfaces, leading to premature failure or damage.

Lahendus: Regularly check the alignment of the bearing and adjust it if necessary. If there are signs of uneven wear, inspect the machine for external stressors that may be causing the misalignment. Precision in the installation process is crucial, and using proper alignment tools and techniques can help ensure the swing bearing remains properly aligned.

Lubrication is vital for the swing bearing’s proper functionality. Insufficient lubrication can cause wear, overheating, and premature failure, while over-lubrication can damage seals and increase the risk of leakage.

Lahendus: Follow the manufacturer’s recommended lubrication schedule and ensure the correct amount of lubrication is applied. Using high-quality lubrication oils compatible with the bearing’s materials is also essential. Regularly check for signs of lubrication issues, such as unusual noises or increased friction, and address them promptly.

Corrosion of the swing bearing can occur due to exposure to moisture or acidic environments. This can lead to surface damage, pitting, and contamination of the lubrication oil, which affects the bearing’s performance.

Lahendus: Regularly inspect and clean the bearing housing to prevent corrosion. If corrosion is detected, remove it using appropriate cleaning methods and apply rust inhibitors to protect the bearing surfaces. Ensuring the excavator is stored in a dry environment and using protective coatings can also help mitigate corrosion risks.

Maintaining and repairing the Swing Bearings 227-6037 for CAT 345DL is crucial for prolonging the lifespan of your excavator and ensuring safe operation. Common challenges such as dust and dirt build-up, misalignment, improper lubrication, and corrosion can lead to costly repairs and pose risks to the operator. However, these issues can be effectively managed through regular inspection, proper cleaning, and adherence to lubrication practices. By following the manufacturer’s recommendations and guidelines, you can avoid unnecessary downtime and ensure your excavator operates efficiently and safely.

Q1: How often should I inspect and lubricate the swing bearing on my CAT 345DL?

Q2: What are the signs of misalignment in a swing bearing?

Q3: How can I prevent dust and dirt build-up in the swing bearing?

Q4: What should I do if I detect corrosion on the swing bearing?

Q5: Why is proper lubrication critical for the swing bearing’s performance?