In the world of heavy machinery, where large equipment performs various rotating operations, the CAT 345BII kiikelaager 227-6094 is a crucial component. This double-row slewing bearing ensures smooth operation and durability of machinery such as cranes and excavators. Proper maintenance of these bearings is essential to extend their lifespan and maintain their functionality. In this blog, we will explore the steps and best practices for maintaining the CAT 345BII Swing Bearing 227-6094 to ensure its normal operation.

A common misconception among customers is that the oil level of the CAT 345BII Swing Bearing 227-6094 should match the lubrication cycle of the machine’s arm, necessitating daily lubrication. In reality, this approach can be counterproductive. Excessive lubrication can lead to dust seal leakage, allowing impurities to enter the bearing and disrupt its normal operation. The optimal lubrication interval for rotating bearings is typically around once every 250 hours. During this process, it is sufficient to apply grease every 15 degrees using a grease gun. The lubrication cycle can be adjusted based on the machine’s working intensity and specific applications.

The maintenance cycle for the rotating motor’s lubricating oil is approximately 1,000 hours. Regularly observing the rotation oil level on the dipstick is crucial. If an abnormal loss of lubricating oil is detected, it is necessary to inspect the large gear ring for leaks, which might indicate that oil has entered the large annular cavity through a faulty seal.

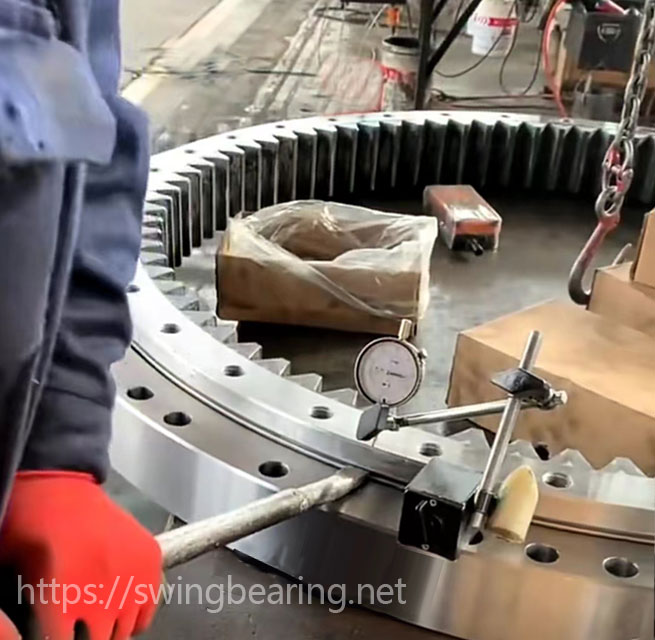

The rotating platform, which includes the gear ring, reduktor, and central component, requires regular maintenance. By opening the lifting rod next to the cover, you can observe the lubrication status of the gear ring cavity and inspect gear wear. Regular inspections help ensure the CAT 345BII Swing Bearing 227-6094 operates smoothly and prevents unexpected failures.

Proper lubrication is critical to the maintenance of the CAT 345BII Swing Bearing 227-6094. Without adequate lubrication, the double-row ball slewing bearing may not function correctly and is prone to wear and tear. Initially, the bearing is supplied with a small amount of grease from the factory. Users must replenish the grease according to the working conditions.

The raceway of the CAT 345BII Swing Bearing 227-6094 should be lubricated at regular intervals. Typically, the steel ball support frame requires lubrication every 100 hours, while the roller support frame needs lubrication every 50 hours. In special working environments—such as tropical, humid, dusty, or those with large temperature differences or continuous operation—the lubrication cycle should be shortened to ensure the bearing’s longevity.

Under heavy workloads, the CAT 345BII Swing Bearing 227-6094 might struggle to rotate. To mitigate this, the amplitude can be reduced, support legs adjusted, or the chassis position moved to redistribute the weight and alleviate stress on the bearing. These adjustments help the bearing perform scheduled lifting operations more efficiently.

If the CAT 345BII Swing Bearing 227-6094 shows signs of damage, immediate technical maintenance is required to prevent further deterioration. By carefully calculating the maximum load and selecting the appropriate bearing, the service life of the CAT 345BII Swing Bearing 227-6094 can be significantly extended.

Maintaining the CAT 345BII Swing Bearing 227-6094 is vital for the smooth operation and longevity of heavy machinery. Proper lubrication, regular inspections, and adjustments for heavy workloads are essential practices for optimal bearing performance. By following these maintenance guidelines, machinery operators can ensure the reliability and efficiency of their equipment.

Q1: Why is proper lubrication crucial for the CAT 345BII Swing Bearing 227-6094?

A1: Proper lubrication is essential to prevent wear and tear, ensure smooth operation, and avoid contamination from dust and impurities. Without adequate lubrication, the bearing may not function correctly and could experience premature failure.

Q2: How often should the CAT 345BII Swing Bearing 227-6094 be lubricated?

A2: The steel ball support frame should be lubricated every 100 hours, and the roller support frame every 50 hours. In special working environments, the lubrication cycle should be shortened to maintain bearing performance.

Q3: What should be done if there is an abnormal loss of lubricating oil?

A3: If an abnormal loss of lubricating oil is detected, inspect the large gear ring for leaks to determine if oil has entered the large annular cavity through a faulty seal. Addressing leaks promptly can prevent further issues.

Q4: How can heavy workloads affect the CAT 345BII Swing Bearing 227-6094?

A4: Heavy workloads can cause the bearing to struggle with rotation. Reducing the amplitude, adjusting support legs, or moving the chassis position can help redistribute the weight and reduce stress on the bearing, facilitating smoother operation.

Q5: What actions should be taken if the CAT 345BII Swing Bearing 227-6094 is damaged?

A5: Immediate technical maintenance is required to prevent further damage. Carefully calculating the maximum load and selecting the appropriate bearing can extend the service life and ensure optimal performance.