When it comes to the efficient and smooth operation of heavy machinery like excavators, every component plays a crucial role. Among these components, swing bearings are paramount. In this blog, we will delve into the specifics of the Caterpillar Excavator E200B swing bearing, discussing its significance, the reasons to choose a particular brand, and the best practices for maintenance and replacement. By the end of this guide, you will have a comprehensive understanding of why the E200B swing bearing is critical to your excavator’s performance.

Swing bearings, also known as slewing bearings or turntable bearings, are pivotal in the functionality of an excavator. These bearings facilitate the smooth rotation of the excavator’s upper structure, allowing it to swing from side to side. This rotational capability is essential for the excavator’s maneuverability and efficiency in performing tasks such as digging, lifting, and placing materials.

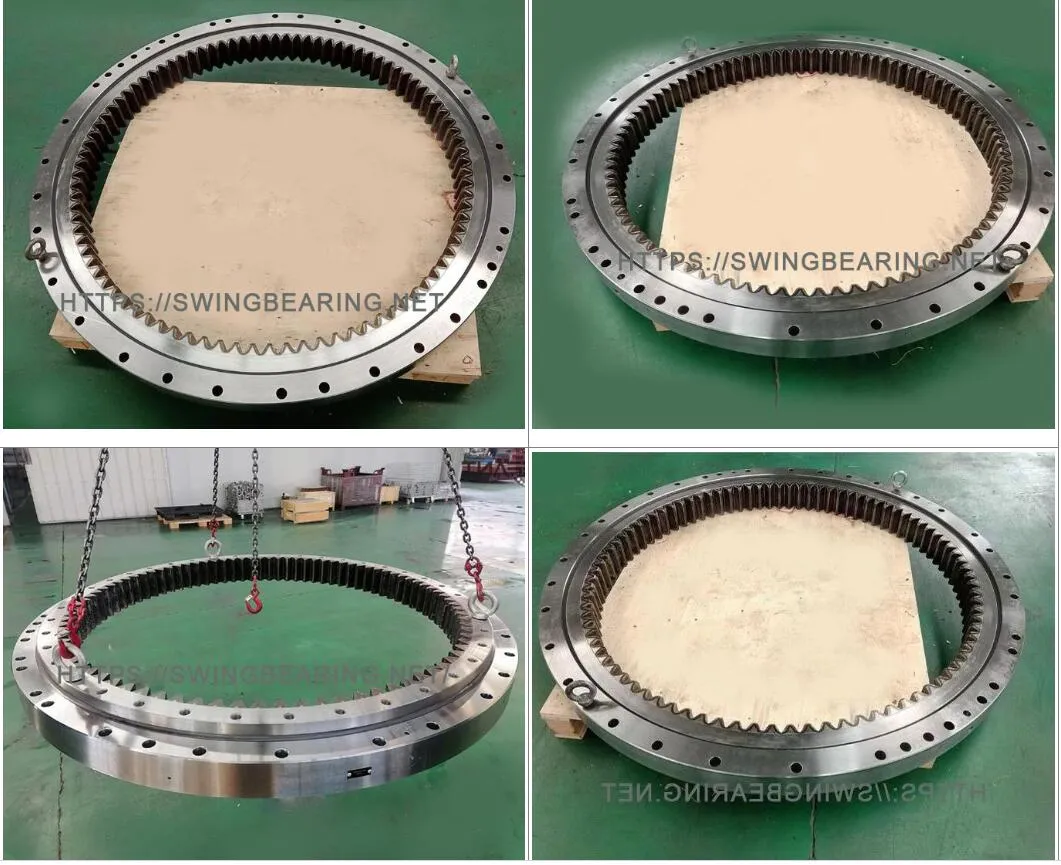

The swing bearing for the Caterpillar Excavator E200B, identified by Part # 085-7964, is designed specifically to meet the demanding needs of this model. Here are some key specifications and features:

The weight and design of the swing bearing are crucial. At 582 lbs, this bearing is robust enough to handle the stresses and strains of daily excavation work. It ensures durability and reliability, two essential qualities for any heavy machinery component. The compatibility with the E200B model means that it is tailored to fit perfectly, ensuring optimal performance.

The construction of the swing bearing involves high-grade materials designed to withstand extreme conditions. Typically, these bearings are made from hardened steel, which provides excellent wear resistance and longevity. The precision engineering ensures that the bearing can handle both radial and axial loads efficiently.

Each swing bearing undergoes rigorous testing to ensure it meets the highest standards of quality and durability. This includes load testing, stress analysis, and fatigue testing. These tests ensure that the bearing can withstand the heavy loads and repetitive movements typical of excavation work.

The E200B swing bearing is built to last, even in the harshest environments. Whether it’s operating in extreme temperatures, handling heavy loads, or dealing with dirt and debris, this bearing is designed to perform consistently. Regular maintenance and proper usage can further extend its lifespan, ensuring you get the most value out of your investment.

Ensuring that your swing bearings are delivered securely and on time is crucial. Any damage during transit can compromise the integrity of the bearing, leading to potential failures and costly downtime.

Our freight shipping process is designed to minimize the risk of damage and ensure timely delivery. Each bearing is carefully packaged to protect it from impacts and vibrations during transit. We work with reliable shipping partners to ensure that your order arrives safely and on schedule.

By ensuring efficient and secure shipping, we help you minimize downtime. When your swing bearing arrives in perfect condition and on time, you can get your excavator back to work quickly, maintaining productivity and reducing costs associated with delays.

Our swing bearings are specifically designed for the Caterpillar E200B excavator. This means they are a perfect fit, ensuring optimal performance and longevity. Using bearings that are tailored for your specific model eliminates the risks associated with using generic parts, such as improper fitting or premature wear.

The bearings replace part numbers 085-7964 and 856757. This compatibility ensures that you are getting a part that meets or exceeds the original equipment manufacturer (OEM) specifications. It also means you can trust that the bearing will work seamlessly with your existing setup.

Meie õõtselaagrid on ehitatud kaevetööde nõudlikele tingimustele vastu pidama ja pakuvad nii vastupidavust kui ka usaldusväärsust. Kvaliteetsete materjalide kasutamine ja ranged testid tagavad, et need laagrid suudavad toime tulla igapäevase tööga seotud surve ja pingetega.

Regulaarne kontrollimine ja määrimine on kiikelaagrite jõudluse ja pikaealisuse säilitamiseks hädavajalik. Kontrollige kulumise, korrosiooni või kahjustuse märke. Veenduge, et laagrid oleksid korralikult määritud, et vähendada hõõrdumist ja kulumist.

Otsige nähtavaid kulumismärke, nagu lõhestumine, koorumine või värvimuutus. Kuulake töö ajal ebatavalisi helisid, mis võivad viidata sisemistele kahjustustele. Kulumise varajane avastamine võib vältida tõsisemaid kahjustusi ja kulukaid remonditöid.

Kasutage kiigelaagrite jaoks soovitatud määrdeainet. Kandke määrdeainet vastavalt tootja juhistele, tagades ühtlase katvuse. Regulaarne määrimine aitab vähendada hõõrdumist, kulumist ja laagririkke ohtu.

Õige ettevalmistus on eduka paigalduse jaoks ülioluline. Veenduge, et tööpiirkond on puhas ja vaba saasteainetest. Koguge enne paigaldamise alustamist kokku kõik vajalikud tööriistad ja seadmed.

Pärast paigaldamist kontrollige põhjalikult, et laager oleks korralikult kinnitatud ja töötaks õigesti. Kontrollige, kas on märke paigutusveast või sidumisest. Regulaarne paigaldusjärgne kontroll aitab vältida tulevasi probleeme ja pikendada laagri kasutusiga.

Swing bearings are critical components in the operation of Caterpillar Excavators, particularly the E200B model. The Part # 085-7964 swing bearing, tailored specifically for this excavator, offers durability, reliability, and optimal performance. Ensuring proper maintenance, timely inspection, and correct installation are key to maximizing the lifespan and efficiency of these bearings. By choosing high-quality, compatible parts and following best practices for care, you can keep your excavator running smoothly and efficiently.

A: Märgid, et teie kiikelaager võib vajada väljavahetamist, on ebatavaline müra töö ajal, nähtav kulumine või kahjustus, suurenenud hõõrdumine ja raskused ekskavaatori ülemise konstruktsiooni pöörlemisel. Regulaarsed ülevaatused aitavad neid märke varakult avastada.

A: Regulaarseid kontrolle tuleks teostada iga päev, kusjuures põhjalikke kontrolle tuleks teha vähemalt kord kuus. Määrimist tuleks teha vastavalt tootja soovitustele, tavaliselt iga 100-200 töötunni järel või rasketes tingimustes sagedamini.

A: Kuigi kiikelaagri on võimalik paigaldada ka ise, kui teil on vajalikud tööriistad ja teadmised, on sageli soovitatav palgata spetsialist. Laagri nõuetekohane paigaldamine on laagri töövõime ja pikaealisuse tagamiseks väga oluline ning professionaal saab tagada, et seda tehakse õigesti.

A: Kasutage kvaliteetset määrdeainet, mis vastab tootja spetsifikatsioonidele teie kiikelaagri jaoks. Tavaliselt on see rasv suure koormuse ja kiirete rakenduste jaoks mõeldud rasvasegu. Konkreetsete soovituste saamiseks vaadake oma seadme kasutusjuhendit.

A: The weight of the swing bearing, such as the 582 lbs for the Caterpillar E200B, indicates its robustness and ability to handle the stresses of excavation work. A heavier bearing typically offers greater durability and reliability, ensuring long-lasting performance under heavy loads.