Excavators are among the most versatile and essential machines on a construction site. Their ability to rotate the housing and arm multiple times in both directions allows operators to efficiently reposition the bucket, adjust the digging angle, and transport materials with remarkable ease. This continuous, omnidirectional rotation is a key feature that enhances the functionality and flexibility of excavators, making them invaluable for various construction tasks.

While the concept of rotation might seem straightforward, the mechanics behind it are quite sophisticated. The seamless rotation of the excavator is achieved through a combination of advanced components and clever engineering. One of the critical yet often overlooked components involved in this process is the swivel, also known as the rotary distributor. Despite its seemingly simple design, the swivel plays a crucial role in connecting the upper and lower hydraulic systems of the excavator, allowing them to operate independently while facilitating smooth rotation.

In this detailed guide, we’ll explore how the excavator swivel works, its importance, common issues that may arise, and its applications beyond excavators.

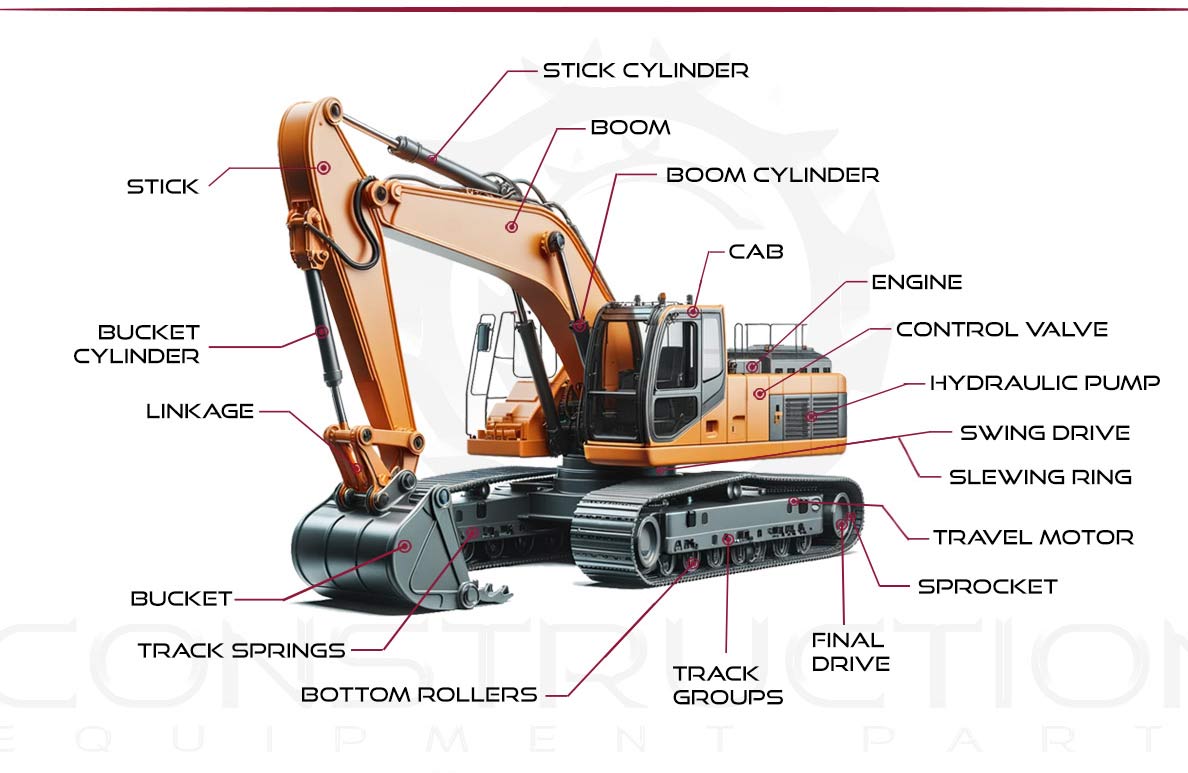

To fully grasp the function of the swivel in an excavator, it’s essential to understand the basic structure of the machine. An excavator consists of two main parts: the upper structure (often referred to as the house) and the lower structure (the undercarriage). The upper structure includes the cab, engine, and boom, while the lower structure houses the components responsible for moving the entire machine.

Many of the excavator’s functions rely on hydraulic power, with hydraulic hoses connecting the upper hydraulic controls, pumps, and valves to the lower motors and final drives. This setup can create a complex network of hoses that may become tangled or damaged due to the machine’s rotation. The swivel addresses this challenge by providing a solution that allows hydraulic connections to rotate without entanglement or disruption.

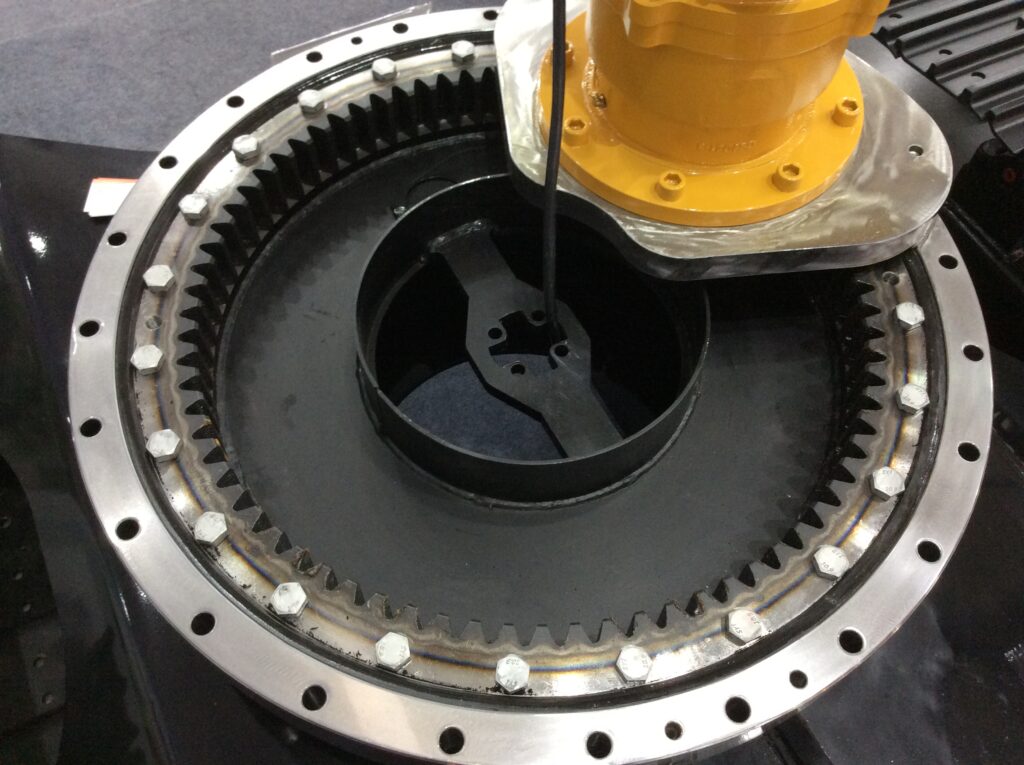

By using a rotary union, the swivel connects the hydraulic hoses from the upper and lower parts of the excavator. It enables the free movement of hydraulic fluid between these sections while accommodating the machine’s rotation. This smart design prevents the hoses from twisting, tangling, or tearing, thus ensuring uninterrupted hydraulic flow and reliable operation.

The excavator swivel is a critical component designed to facilitate the smooth rotation of the machine while maintaining a continuous hydraulic connection. It consists of a center shaft and an outer housing, with fluid passages integrated into both parts.

The basic operation of the swivel involves:

Despite its robust design, the excavator swivel can encounter issues over time. Common problems include hydraulic leaks and component wear.

Regular inspection and maintenance of the swivel are crucial to address these issues promptly and prevent further damage to the excavator’s hydraulic system.

The design principles of the excavator swivel are not limited to construction machinery. The concept of a rotary union, also known as a rotary manifold or fluid swivel, is utilized in various applications beyond excavators. This design allows for the free passage of fluids or gases while maintaining rotational movement, making it suitable for:

These applications demonstrate the versatility and importance of the swivel design in various industrial contexts.

The excavator swivel is a vital component that plays a significant role in the machine’s ability to rotate smoothly and efficiently. By connecting the upper and lower hydraulic systems while allowing for independent rotation, the swivel ensures uninterrupted hydraulic flow and optimal performance. Understanding how the swivel works, recognizing common issues, and appreciating its broader applications can help in maintaining and troubleshooting excavators effectively.