Unveiling the Hidden Power: Locating the Slewing Ring in an Excavator

The slewing ring(slew ring), also known as the swing bearing,is a critical component in an excavator. It is located at the base of the excavator’s upper structure and allows the upper structure to rotate relative to the undercarriage. The slew ring is responsible for transferring the weight of the upper structure and the digging forces to the undercarriage. It also allows the excavator to swing from side to side.

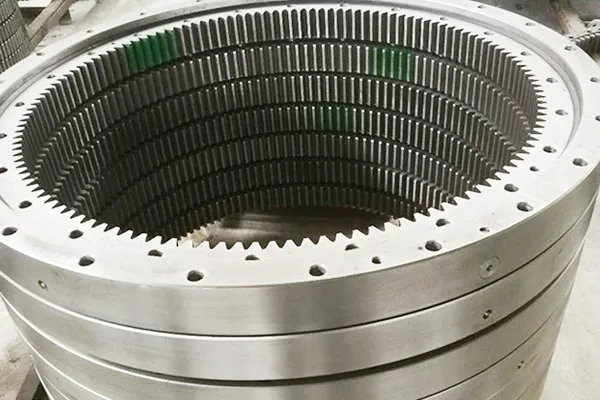

Excavator slew ring

The Drejekrans, a crucial component in an excavator, plays a pivotal role in enabling the machine’s upper structure to rotate smoothly upon its lower structure. Understanding its location is essential for maintenance and repair purposes.

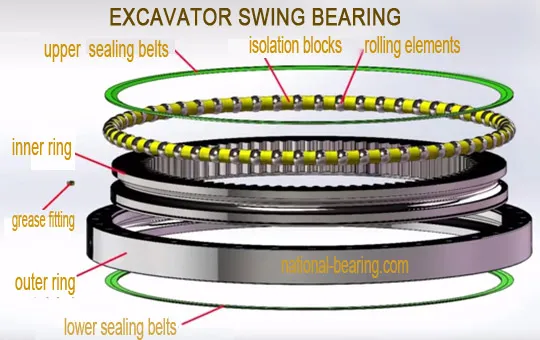

The swing bearing is typically situated at the base of the excavator’s upper structure, where it interfaces with the lower structure. It consists of two concentric rings, one fixed to the upper structure and the other to the lower structure. The rings are separated by a series of rolling elements, such as ball bearings or rollers, which facilitate rotation.

To locate the swing bearing, begin by identifying the excavator’s upper and lower structures. The upper structure is the part that houses the cab, boom, and arm, while the lower structure comprises the tracks or wheels and the undercarriage.

Once the upper and lower structures are identified, look for the point where they connect. This is typically a circular or hexagonal opening in the center of the upper structure. The slew ring is located within this opening.

In some excavators, the swing bearing may be partially or fully enclosed by a protective housing. This housing serves to keep the slew ring clean and lubricated, extending its lifespan. To access the slew ring, it may be necessary to remove the housing.

The location of the slew ring can vary slightly depending on the specific excavator model and manufacturer. However, it is generally found at the base of the upper structure, where it provides a stable and reliable connection between the upper and lower structures.

Understanding the location of the slew ring is crucial for maintenance and repair tasks. Regular inspection and lubrication of the slew ring are essential to ensure its proper functioning and prevent premature wear or failure. By knowing where to find the slew ring, technicians can efficiently perform these tasks, maximizing the excavator’s performance and longevity.

The swing bearing, a crucial component in an excavator, is located at the base of the upper structure, where it connects to the lower structure. This strategic placement allows the upper structure to rotate smoothly and efficiently, enabling the excavator to perform a wide range of tasks.

The slew ring consists of two main components: an inner gear and an outer gear. The inner gear is attached to the upper structure, while the outer gear is fixed to the lower structure. As the excavator operator activates the slew motor, the inner gear rotates, driving the outer gear and causing the upper structure to turn.

The slew ring plays a vital role in the excavator’s functionality. It provides a stable and reliable connection between the upper and lower structures, ensuring smooth and precise rotation. Without a properly functioning slew ring, the excavator would be unable to perform its intended tasks effectively.

The location of the slew ring at the base of the upper structure is not only practical but also advantageous. This placement allows for easy access during maintenance and repairs, minimizing downtime and ensuring the excavator’s continued operation.

In addition to its primary function, the slew ring also contributes to the excavator’s overall stability. By providing a solid connection between the upper and lower structures, it helps to distribute the weight of the excavator evenly, preventing it from tipping over during operation.

Furthermore, the slew ring’s location at the base of the upper structure allows for the installation of additional components, such as hydraulic lines and electrical wiring. These components are essential for the excavator’s operation and are conveniently routed through the slew ring, ensuring their protection and functionality.

In conclusion, the slew ring is a critical component in an excavator, located at the base of the upper structure. Its strategic placement enables smooth rotation, provides stability, and facilitates the installation of essential components. Understanding the function and importance of the slew ring is crucial for ensuring the efficient and reliable operation of an excavator.

The slewing ring is a vital component in an excavator, playing a pivotal role in enabling the upper structure to rotate smoothly upon the undercarriage. Understanding its location, structure, and function is essential for troubleshooting common issues related to this critical part. This detailed guide will help you identify, diagnose, and resolve problems associated with the slewing ring, ensuring your excavator operates efficiently.

The slewing ring is typically situated at the base of the excavator’s upper structure, where it interfaces with the lower frame. It comprises two concentric rings: one fixed to the upper structure and the other to the lower frame. Between these rings are rolling elements, such as ball bearings or rollers, that facilitate the rotation of the upper structure.

To access the slewing ring, it is necessary to remove the upper structure from the undercarriage. This involves several steps:

Once the upper structure is detached, the slewing ring becomes visible as a large, circular component located at the base of the upper frame.

The primary function of the slewing ring is to facilitate the rotation of the excavator’s upper structure relative to its undercarriage. This allows the operator to maneuver the boom, arm, and bucket with precision, enhancing the excavator’s versatility and efficiency. The slewing ring must withstand significant loads and stresses during operation, making its proper maintenance and functioning critical.

One of the most common issues with the slewing ring is excessive wear. This can result from various factors, including heavy usage, inadequate lubrication, and contamination. Symptoms of excessive wear include:

To diagnose excessive wear, perform the following checks:

If excessive wear is confirmed, take the following steps:

Proper lubrication is crucial for the smooth operation and longevity of the slewing ring. Inadequate or incorrect lubrication can lead to increased friction, overheating, and premature failure.

Signs of lubrication problems include:

To resolve lubrication issues:

Svingleje til gravemaskine

Bearing failure in the slewing ring can have severe consequences, including total operational shutdown. This issue can be caused by various factors, including overloading, poor maintenance, and manufacturing defects.

Symptoms of bearing failure include:

If bearing failure is suspected:

Regular monitoring and maintenance are crucial for preventing issues with the slewing ring and ensuring its optimal performance.

Perform scheduled inspections to identify potential issues before they become severe:

Ensure that operators and maintenance personnel are adequately trained:

The slewing ring is a critical component of an excavator, enabling the upper structure to rotate smoothly upon the undercarriage. Understanding its location, structure, and function is essential for troubleshooting common issues and ensuring optimal performance. By regularly inspecting, maintaining, and addressing issues such as excessive wear, lubrication problems, and bearing failure, you can prolong the life of the slewing ring and enhance the overall efficiency and reliability of your excavator.

By following these detailed maintenance practices, you can ensure that your excavator’s hydraulic system remains in top condition, providing reliable performance and longevity. Regular monitoring, proper lubrication, and timely replacement of worn components are key to preventing common issues and maintaining the efficiency of the slewing ring.

The structure of slewing ring

1. Where is the slewing ring located in an excavator?

– The slew ring is located between the upper and lower structures of the excavator.

2. What is the function of the slew ring in an excavator?

– The slew ring allows the upper structure of the excavator to rotate relative to the lower structure.

3. What are the different types of slew rings used in excavators?

– There are two main types of slew rings used in excavators: ball bearing slew rings and roller bearing slew rings.

The slew ring, also known as the swing bearing, is a crucial component located at the base of an excavator’s upper structure. It provides support and allows the upper structure to rotate smoothly on the lower structure, enabling the excavator to perform digging and excavation operations with precision and efficiency.