Ensuring the precise clearance measurement of excavator slewing bearing during assembly is crucial for the machinery’s optimal performance and longevity. Accurate measurement of axial and radial clearances helps prevent operational issues and extends the bearing’s service life. This blog provides a detailed guide on how to measure these clearances during assembly.

Slewing bearings are essential components in excavators, responsible for the smooth rotation and load distribution of the upper structure. Proper clearance measurement during assembly is critical to ensure the bearing functions correctly and to avoid premature wear or failure. This guide details the steps and considerations for accurately measuring the axial and radial clearances of excavator slewing bearings.

Axial clearance measurement is the first step in ensuring the proper fit and function of a slewing bearing. Here is a step-by-step process for measuring axial clearance:

Begin by uniformly tightening the connecting screws of the double half rings in the slewing bearing. This ensures an even fit and prevents any distortion during measurement.

Place the slewing bearing’s datum level on a large, stable platform. Ensure that the bearing is level and stable to obtain accurate measurements.

Equidistantly place three adjustable bearings from the neutral position of the lower two steps of the slewing bearing. This positioning ensures consistent measurement points.

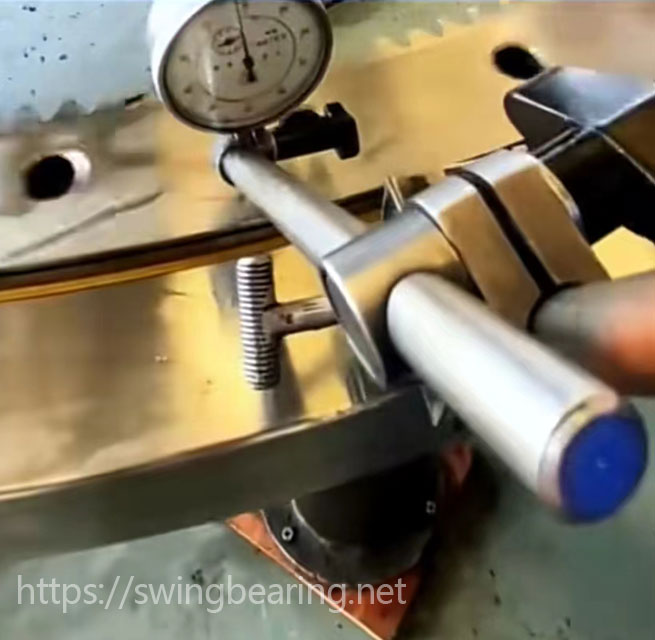

Equidistantly place three measuring frames on the end face of the upper slewing ring. Attach the pointers of these frames to the end face of the lower slewing ring.

To measure the axial clearance:

This method ensures a precise measurement by averaging the readings from multiple points, thereby accounting for any minor discrepancies.

Radial clearance measurement is equally important and involves the following steps:

Place the slewing bearing vertically on the platform to ensure it is in a stable and consistent position for accurate measurement.

Lift one slewing ring slightly, using the dead weight of the other slewing ring to measure the clearance. This step ensures that the measurement is taken without additional external forces that could distort the reading.

Measure the clearance at three equidistant points along the circumference (every 120°). This approach ensures a comprehensive assessment of the bearing’s radial clearance.

Take the average of the three measurements to determine the radial clearance. Averaging multiple measurements helps mitigate any inconsistencies and provides a more accurate overall clearance.

Accurate measurement of axial and radial clearances during the assembly of excavator slewing bearings is vital for ensuring the longevity and optimal performance of the machinery. By following the detailed steps outlined above, you can achieve precise clearance measurements, thereby preventing operational issues and extending the bearing’s service life.

A: Measuring both axial and radial clearances ensures that the slewing bearing is properly aligned and can handle the loads and movements it will encounter during operation. Proper clearance measurements prevent premature wear and operational failures.

A: Clearance measurements should be checked during the initial assembly and periodically during maintenance inspections. The frequency depends on the operating conditions and manufacturer recommendations, but generally, it should be done at regular intervals to ensure ongoing optimal performance.

A: For axial clearance measurement, you need a stable platform, adjustable bearings, measuring frames, and precision pointers. For radial clearance measurement, you need a stable vertical platform and a reliable method to lift and measure the slewing rings accurately.

A: Common signs include unusual noises, increased vibration, uneven rotation speed, and unexpected wear patterns. If any of these signs are observed, it is crucial to re-measure the clearances to diagnose and rectify potential issues.

By following these guidelines and regularly monitoring the clearances, you can ensure the efficient and reliable operation of your excavator’s slewing bearing, thereby enhancing the overall performance and lifespan of your machinery.