Hydraulic systems are the lifeblood of modern excavators, providing the power necessary to perform a wide range of tasks, from digging trenches to lifting heavy loads. Central to these systems is the hydraulic pump, which generates the hydraulic energy needed to operate the excavator’s various functions. Understanding the intricacies of hydraulic pumps and their role in the overall hydraulic system is crucial for operators and technicians alike.

A hydraulic system is a mechanism that uses fluid power to perform work. In excavators, hydraulic systems convert mechanical energy from the engine into hydraulic energy through the hydraulic pump. This energy is then used to move cylinders, motors, and other components, enabling the excavator to perform tasks with precision and efficiency.

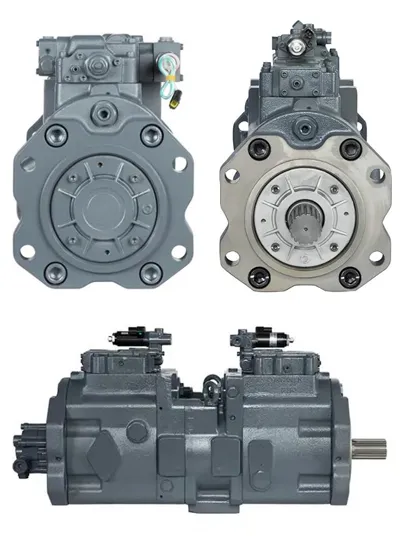

There are several types of hydraulic pumps used in excavators, each with its own advantages and applications. The most common types include gear pumps, vane pumps, and piston pumps. Understanding the differences between these pumps can help in selecting the right one for specific excavator applications.

Gear pumps are one of the simplest types of hydraulic pumps. They consist of two meshing gears that rotate to move fluid through the system. These pumps are known for their durability and ease of maintenance.

Gear pumps are often used in systems where steady, high-pressure flow is required. They are suitable for tasks such as powering auxiliary hydraulic circuits in excavators.

Vane pumps use a series of sliding vanes within a rotating cylinder to move fluid. They are known for their smooth operation and ability to handle variable flow rates.

Vane pumps are commonly used in applications requiring variable flow rates, such as controlling the boom and arm movements of an excavator.

Piston pumps are the most complex and versatile type of hydraulisk pumpe. They use a series of pistons to move fluid, providing precise control and high pressure.

Piston pumps are used in primary hydraulic systems of excavators, where precise control and high pressure are essential, such as in the operation of the main boom, arm, and bucket.

The hydraulic pump is the heart of the hydraulic system in an excavator. Its primary function is to convert mechanical energy from the engine into hydraulic energy, which is then used to perform various functions. The performance and efficiency of an excavator largely depend on the proper functioning of its hydraulic pump.

The hydraulic pump generates hydraulic energy by pressurizing the hydraulic fluid. This pressurized fluid is then directed through hoses and valves to the hydraulic cylinders and motors, enabling the excavator to perform its tasks. The efficiency of this process is crucial for the overall performance of the excavator.

Hydraulic pumps are responsible for controlling the flow and pressure of the hydraulic fluid. By adjusting the pump settings, operators can control the speed and force of the excavator’s movements. This is essential for tasks that require precision and careful handling.

A well-maintained hydraulic pump ensures the overall efficiency of the hydraulic system. By providing consistent and reliable hydraulic power, the pump allows the excavator to operate smoothly and efficiently. Regular maintenance and proper operation of the pump are key to avoiding downtime and costly repairs.

Regular maintenance of hydraulic pumps is essential to ensure their longevity and performance. This involves routine checks, fluid changes, filter replacements, and inspections. Proper maintenance can prevent common issues such as leaks, wear, and contamination, ensuring the hydraulic system operates efficiently.

Hydraulic fluid is the lifeblood of the hydraulic system. It transmits power, lubricates components, and helps in cooling the system. Over time, hydraulic fluid can become contaminated with particles and moisture, reducing its effectiveness. Regularly checking and changing the hydraulic fluid is crucial for maintaining the health of the hydraulic pump and the entire system.

Hydraulic filters remove contaminants from the hydraulic fluid, protecting the components from wear and damage. Over time, these filters can become clogged, reducing their effectiveness and potentially causing damage to the hydraulic pump and other components.

Seals and hoses are critical components of the hydraulic system. They contain the hydraulic fluid and ensure that it is delivered to the right places within the system. Over time, seals and hoses can wear out, leading to leaks and reduced system performance.

Hydraulic leaks can significantly reduce system efficiency and pose environmental hazards. They can also lead to a loss of hydraulic fluid, which can damage the hydraulic pump and other components.

Despite regular maintenance, hydraulic pumps can sometimes experience issues that need troubleshooting. Understanding common problems and their solutions can help keep the hydraulic system in optimal condition.

To maximize the performance of hydraulic pumps, it’s essential to follow best practices in operation and maintenance. This includes proper training for operators, regular system checks, and staying updated with the latest advancements in hydraulic technology.

Proper training for operators is crucial for the efficient and safe operation of hydraulic systems. Well-trained operators can identify potential issues early, use the equipment correctly, and perform basic maintenance tasks.

Conduct daily inspections of the hydraulic system to identify any issues early. This includes checking fluid levels, inspecting hoses and seals, and looking for signs of leaks or damage.

Follow a scheduled maintenance plan that includes fluid changes, filter replacements, and detailed system inspections. Adhering to this plan can prevent unexpected breakdowns and extend the lifespan of the hydraulic pump.

Stay updated with the latest advancements in hydraulic technology. Innovations such as variable displacement pumps, electronic control systems, and advanced filtration technologies can enhance the performance and efficiency of hydraulic systems.

Consider integrating new technologies into existing hydraulic systems to improve performance. This may involve upgrading components, using more advanced