Na stránkách CAT 345BL 169-5536 Swing Bearing is a critical component in the world of heavy machinery, specifically designed to handle substantial axial loads, radial loads, and overturning moments. Known for its robust construction and high safety factor, this swing bearing is commonly utilized in various mechanical equipment such as medium to large cranes, mining equipment, and excavators. In this blog, we will delve into the details of the CAT 345BL 169-5536 Swing Bearing, exploring its construction, heat treatment processes, applicable temperature ranges, and working environments, as well as its unique characteristics and advantages.

The CAT 345BL 169-5536 Swing Bearing, often referred to as a “mechanical joint” in the industry, is essential for facilitating the relative rotation between two objects while bearing axial force, radial force, and overturning moments. This bearing comprises two rows of ball-shaped rollers that provide it with the capacity to support large loads efficiently. This design ensures higher safety and reliability, making it ideal for demanding applications in heavy machinery.

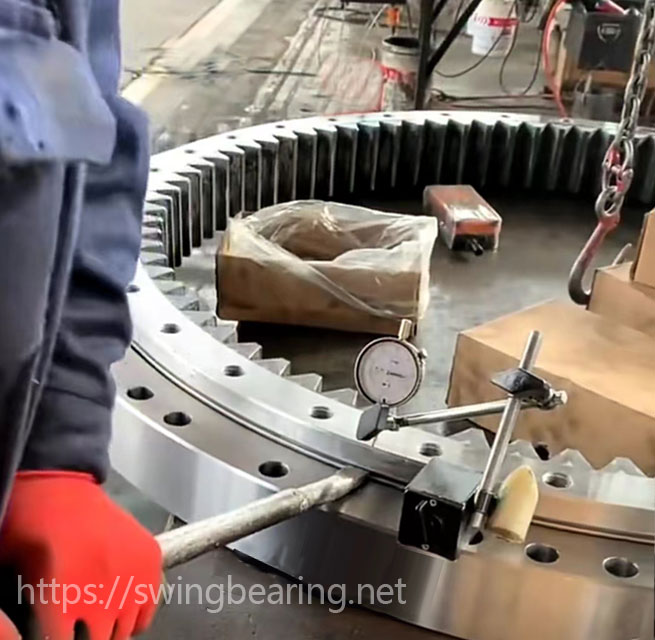

The raceway of the CAT 345BL 169-5536 Swing Bearing undergoes surface induction hardening, achieving a hardness depth of HRC55-62 through quenching and hardening processes. This treatment ensures that the bearing can withstand significant stress and wear. Since these bearings are involved in transmission, they are typically constructed from one of the rings. The heat treatment status of the gear associated with this bearing is usually normalizing or quenching and tempering. For applications requiring higher durability, the tooth surface can be quenched to a hardness of HRC50-60. Gear quenching methods vary based on application needs and can include full tooth quenching or single tooth induction quenching, with further subdivisions into tooth surface and tooth root quenching.

The CAT 345BL 169-5536 Swing Bearing is designed to operate efficiently within a broad temperature range of -300°C to 700°C. This wide range makes it adaptable to various environments, including those with extreme temperatures. In particularly harsh conditions such as marine climates, environments with abrasive particles, or industries dealing with cement and coal, special seals, protective devices, and appropriate lubricants are essential. Regular maintenance and proper protection ensure that these bearings function optimally, even under challenging conditions.

The CAT 345BL 169-5536 Swing Bearing, a double row ball slewing bearing, shares some similarities with conventional bearings, such as rolling elements and seat rings. However, it stands out due to its distinct features. These bearings are larger, sturdier, and designed to handle a combination of axial forces, radial forces, and substantial overturning moments. This capability allows them to bear various loads simultaneously, making them suitable for applications like tower cranes and car cranes.

Double row ball slewing bearings like the CAT 345BL 169-5536 typically operate at low speeds, usually around 50 rpm. In many applications, these bearings do not rotate continuously but instead move at specific angles. Manufacturing processes for these bearings, including material selection and heat treatment, differ significantly from those of rolling bearings. They often feature gear rings for rotational drive and sealing devices for dust prevention. Installation methods also vary; unlike ordinary spindle bearings, double row ball slewing bearings are installed in bearing boxes and secured to the upper and lower bearings using screws.

The CAT 345BL 169-5536 Swing Bearing is a vital component in heavy machinery, designed to handle significant loads and withstand harsh operating conditions. Its robust construction, advanced heat treatment processes, and adaptability to extreme temperatures make it indispensable for applications in cranes, mining equipment, and excavators. Understanding the unique characteristics and maintenance requirements of these bearings can help ensure their optimal performance and longevity.

Q1: What makes the CAT 345BL 169-5536 Swing Bearing suitable for heavy machinery?

A1: The CAT 345BL 169-5536 Swing Bearing is designed to handle large axial loads, radial loads, and overturning moments due to its robust construction and two rows of ball-shaped rollers. This makes it highly reliable and suitable for demanding applications in heavy machinery such as cranes, mining equipment, and excavators.

Q2: How does the heat treatment process enhance the performance of the CAT 345BL 169-5536 Swing Bearing?

A2: The heat treatment process, including surface induction hardening and quenching, increases the hardness of the bearing’s raceway and gear surfaces, enhancing their ability to withstand stress, wear, and impact. This results in improved durability and longevity of the bearing under heavy loads and harsh conditions.

Q3: What temperature range can the CAT 345BL 169-5536 Swing Bearing operate within?

A3: The CAT 345BL 169-5536 Swing Bearing can operate efficiently within a wide temperature range of -300°C to 700°C. This makes it adaptable to various environments, including extreme temperatures and harsh conditions.

Q4: Why is regular maintenance important for the CAT 345BL 169-5536 Swing Bearing?

A4: Regular maintenance is crucial for ensuring the optimal performance and longevity of the CAT 345BL 169-5536 Swing Bearing. Proper maintenance, including the use of special seals, protective devices, and appropriate lubricants, helps prevent issues caused by wear, contamination, and harsh operating conditions.

Q5: What are the unique characteristics of double row ball slewing bearings like the CAT 345BL 169-5536?

A5: Double row ball slewing bearings are larger, sturdier, and capable of handling a combination of axial forces, radial forces, and substantial overturning moments. They often feature gear rings for rotational drive, sealing devices for dust prevention, and are installed differently from conventional bearings. These characteristics make them suitable for applications requiring high load-bearing capacity and reliable performance.